Water stop ring with split type hinge rubber ring

A hinged apron, split-type technology, applied in shaft lining, tunnel lining, underground chamber, etc., can solve problems such as difficult to ensure construction safety, reduce work efficiency, deformation of water-stop apron, etc., and achieve good anti-leakage The effect of improving work efficiency and improving the jacking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 is a scheme in which the ventilation pipe and the rubber water stop ring are integrally formed:

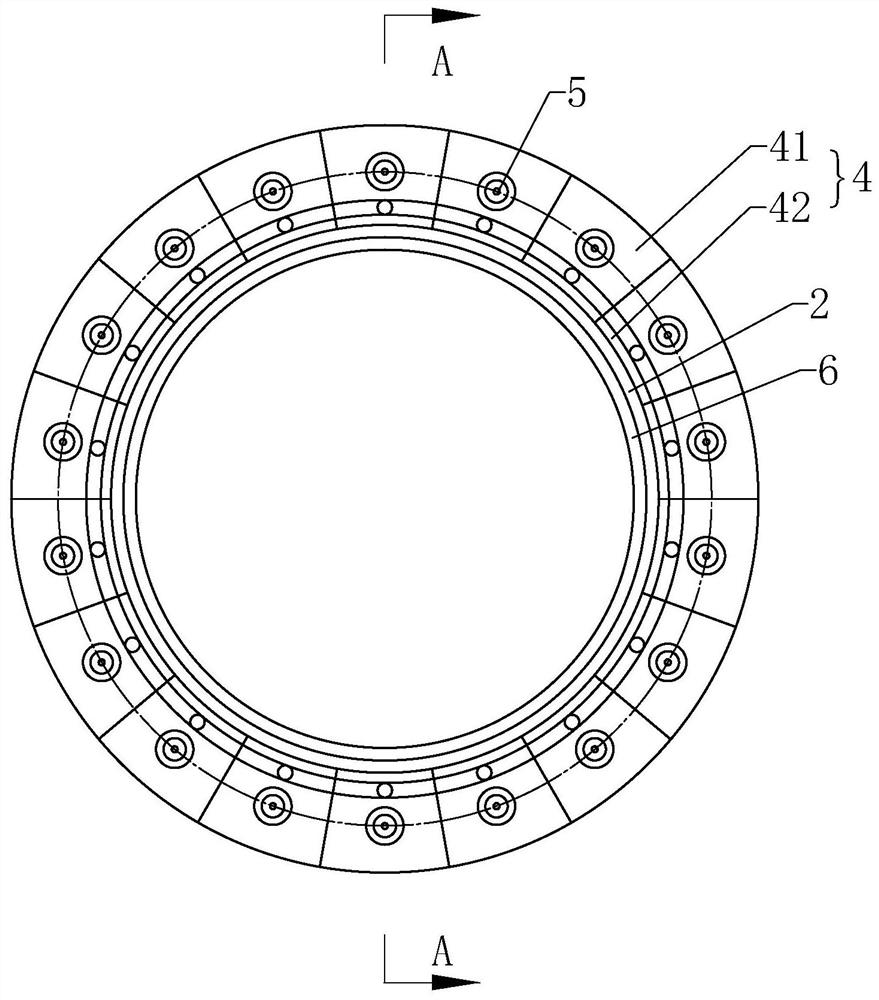

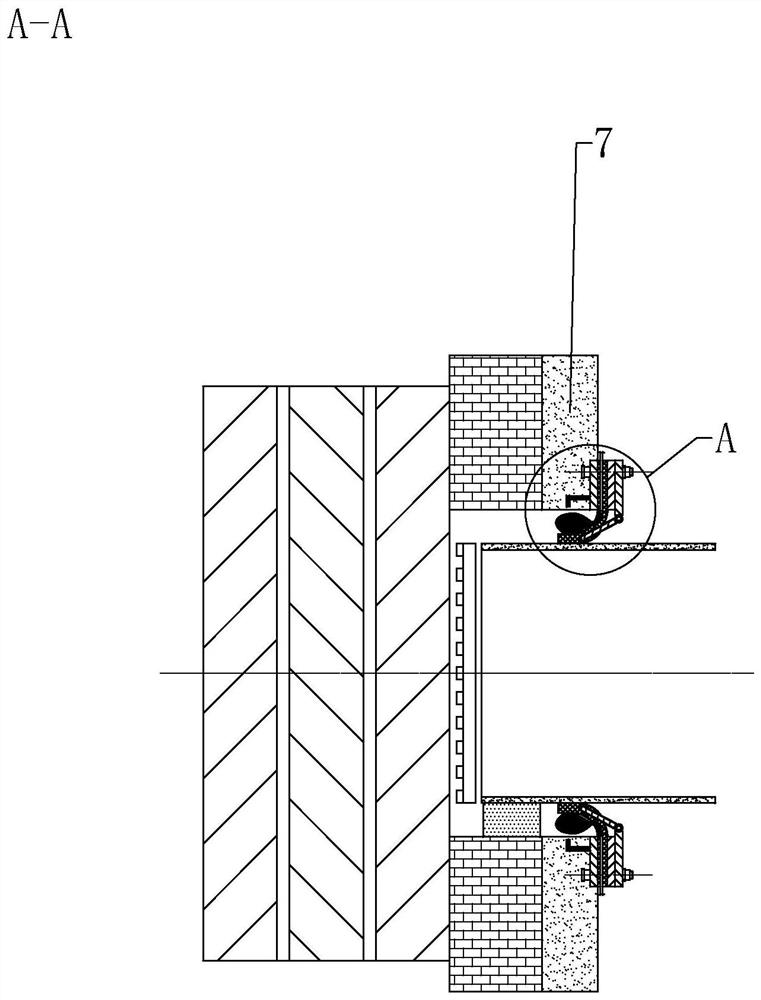

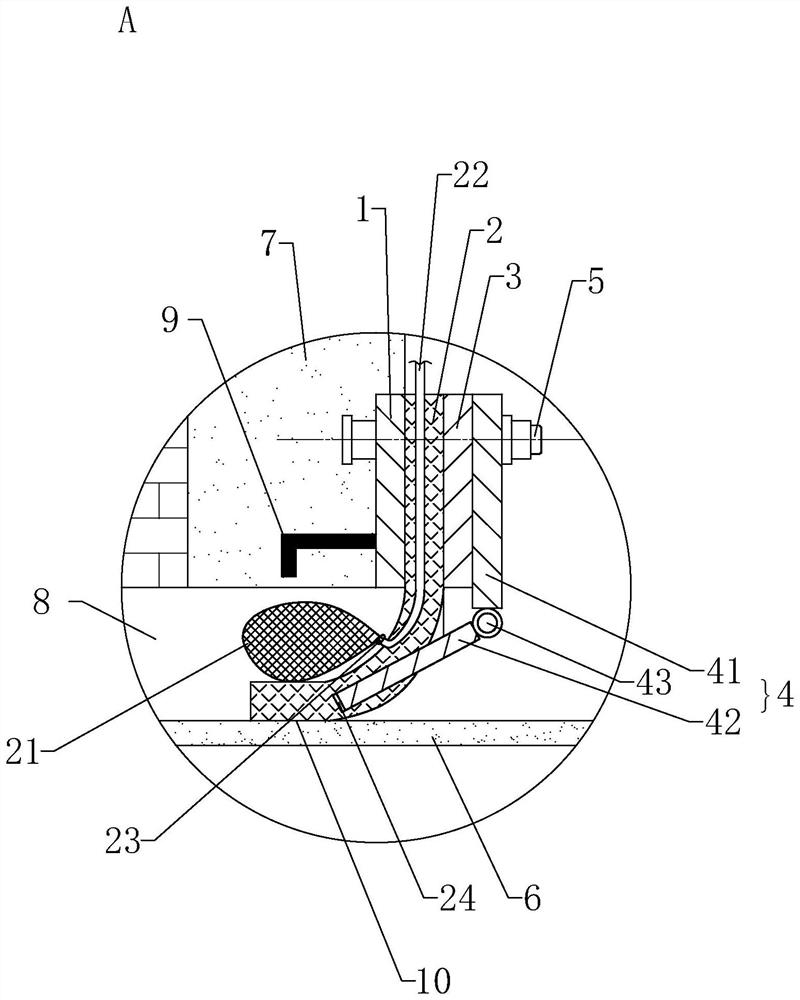

[0029] First, install several pre-embedded bolts along the circumferential direction on the wall of the entrance to the hole, install the airbag on the vent pipe slidingly connected with the rubber water stop ring through at least one check valve, and then install the pre-embedded bolts in sequence through the pre-embedded bolts. The steel ring plate, the rubber water stop ring, the steel pressure ring and the hinge pressure plate are compressed by the compression nut, and the hinge of the hinge pressure plate is inserted into the hinge slot of the rubber water stop ring.

[0030] as attached figure 2 to attach image 3 As shown in the figure, after the pipe jacking machine is pushed into the hole and the machine head passes through the hinge plate, the air filling device controls the inflation of the air bag installed between the inner wall of the well hole ...

Embodiment 2

[0032] Embodiment 2 is a scheme in which the ventilation pipe and the rubber water stop ring are slidably and fixedly connected:

[0033] First, install several pre-embedded bolts along the circumferential direction on the wall of the entrance to the hole, install the airbag on the vent pipe slidingly connected with the rubber water stop ring through at least one check valve, and then install the pre-embedded bolts in sequence through the pre-embedded bolts. The steel ring plate, the rubber water stop ring, the steel pressure ring and the hinge pressure plate are compressed by the compression nut, and the hinge of the hinge pressure plate is inserted into the hinge slot of the rubber water stop ring.

[0034] as attached figure 2 to attach image 3As shown in the figure, after the pipe jacking machine is pushed into the hole and the machine head passes through the hinge plate, the air filling device controls the inflation of the air bag installed between the inner wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com