Blasting type mine single supporting pillar

A single-pillar technology, used in blasting cylinders, pillars/supports, mining equipment, etc., can solve the problems of complex hydraulic systems, difficult to move turnover, and high machining accuracy, achieve high operational flexibility, reduce manufacturing costs, and reduce machining accuracy. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

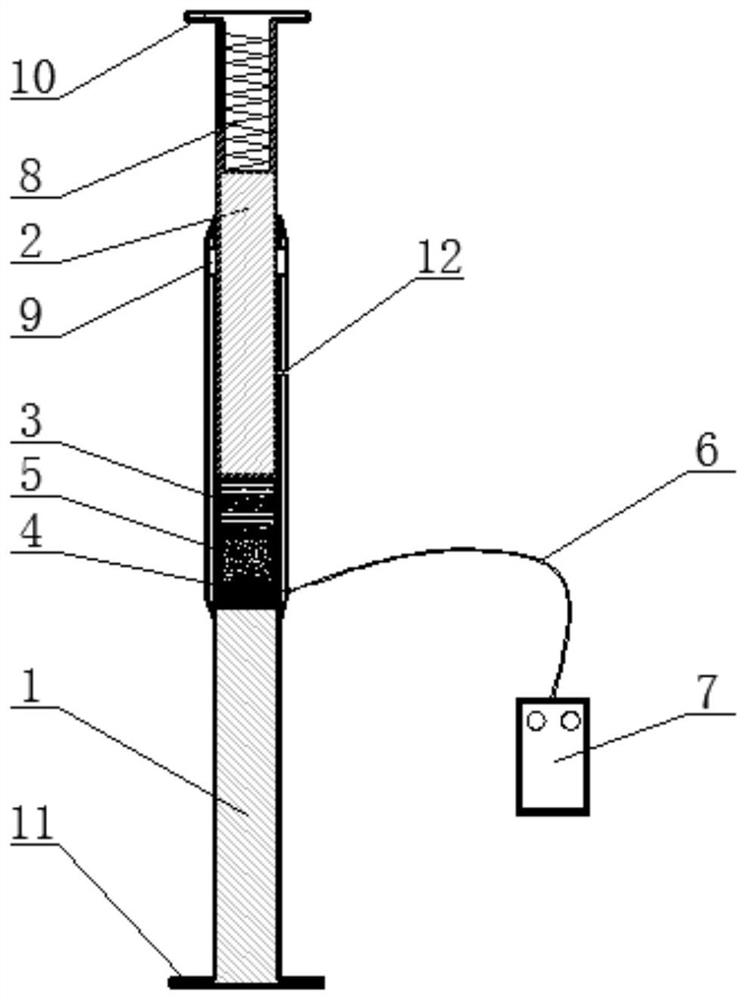

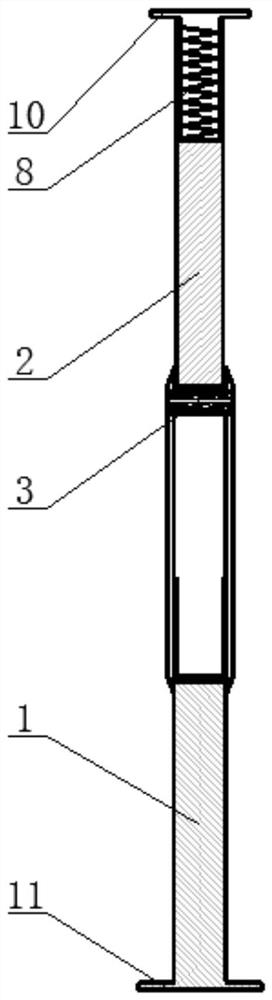

[0020] like figure 1 , figure 2 As shown, the present invention provides a blasting type mine single support pillar, including a base 1 and a push rod 2, a receiving groove is arranged on the base 1, and an elastic member 3 is fixedly connected to one end of the push rod 2 and is sleeved in the receiving groove , the other end of the push rod 2 extends outwards, and the detonator 4 and the gunpowder 5 are sequentially filled between the bottom of the receiving tank and the elastic member 3, and the detonator 4 is electrically connected to the detonator 7 arranged outside through a wire 6.

[0021] Further, it is preferred that the material of the elastic member 3 is 7075 aluminum alloy. A height adjuster 8 is also embedded in the push rod 2 . The height adjuster 8 is a cylindrical helical compression spring.

[0022] In additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com