Rotating shaft fault detection system and method based on vision measurement

A visual measurement and fault detection technology, which is applied in the direction of measuring devices, optical testing of flaws/defects, and material analysis through optical means, can solve problems such as expensive testing costs, low efficiency, and susceptibility to noise interference, and achieve high-efficiency measurement, Efficient and convenient detection, the effect of efficient analysis of the dynamic characteristics of the shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

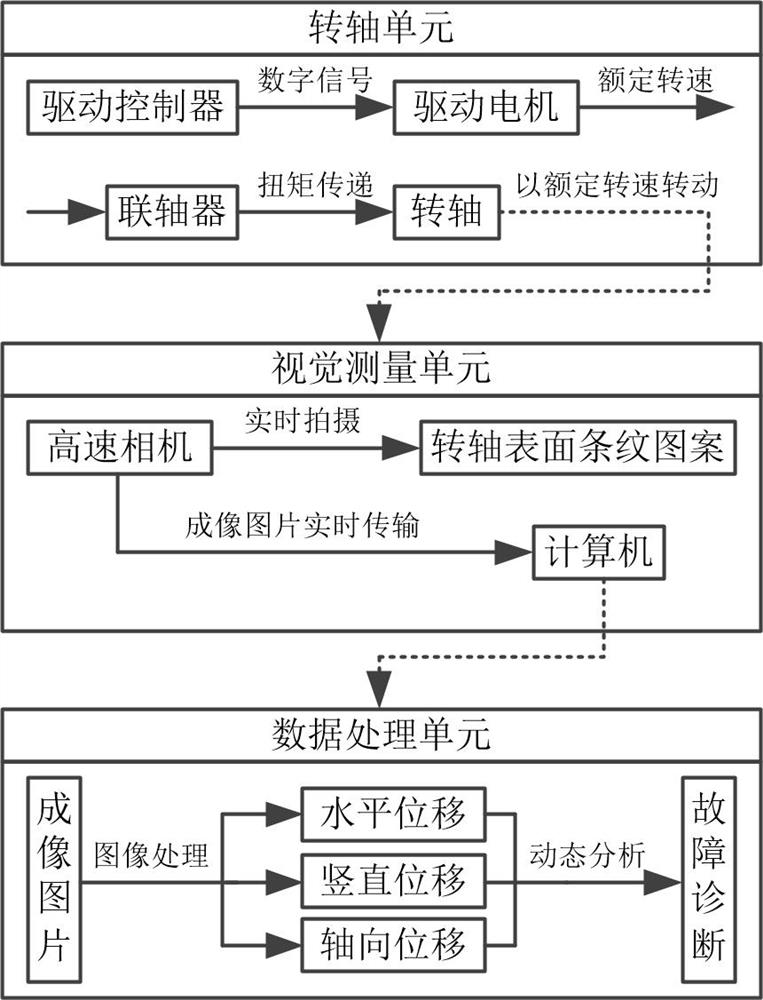

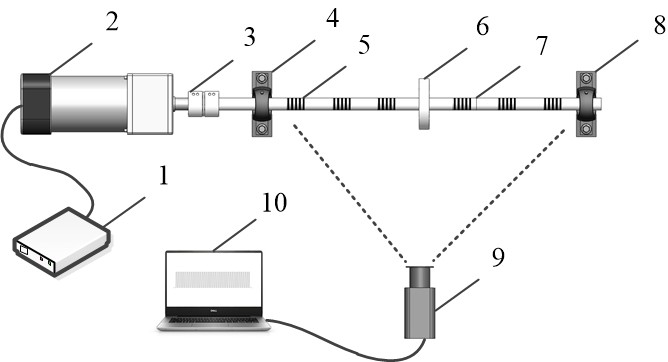

[0026] Please refer to figure 1 , the present invention provides a rotating shaft fault detection system based on visual measurement, including a drive controller 1, a drive motor 2, a coupling 3, a left end bearing 4, a rotating shaft 5, a counterweight disc 6, a crack 7, and a right end bearing 8 , high-speed camera 9, computer 10. Different types of digital signals generated in the drive controller 1 control the drive motor 2 to rotate at a rated speed. The drive motor 2 is connected to the rotating shaft 5 through the coupling 3. The rotating shaft 5 is supported by the left end bearing 4 and the right end bearing 8 respectively. The rotating shaft 5 The length is 620 mm, the diameter is 10 mm, the material elastic modulus is 210000 N / mm², and the material density is 7850 g / mm 3 . A counterweight disc 6 is arranged in the middle of the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com