Monolithic insulation test tool for carbon ceramic linear resistor

A linear resistance and insulation test technology, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of inability to perform separate insulation tests on a single piece of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

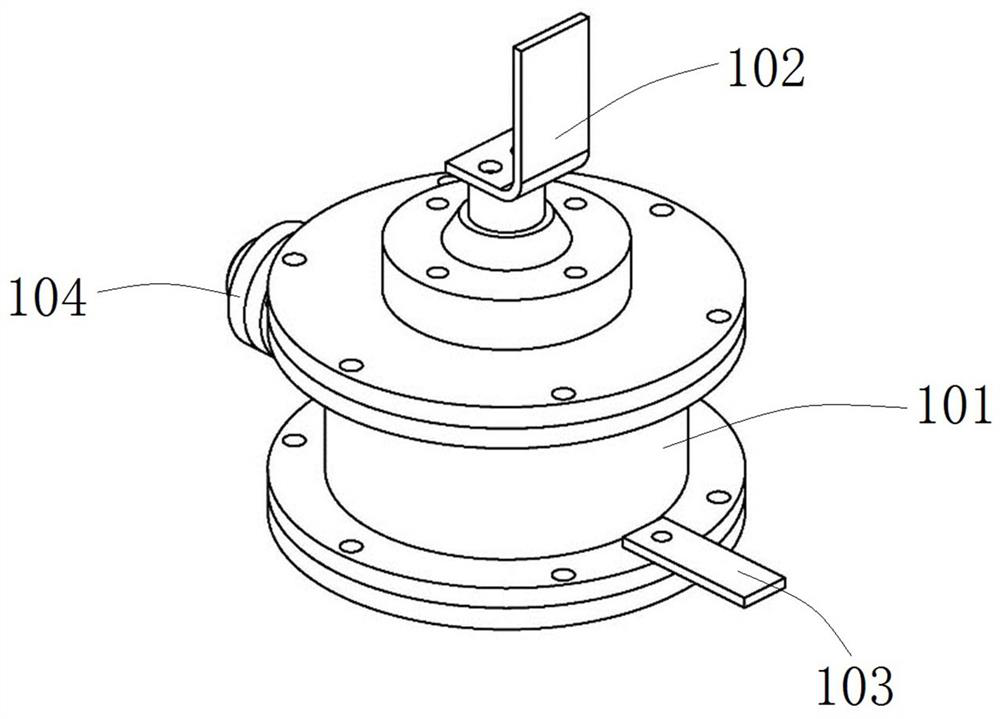

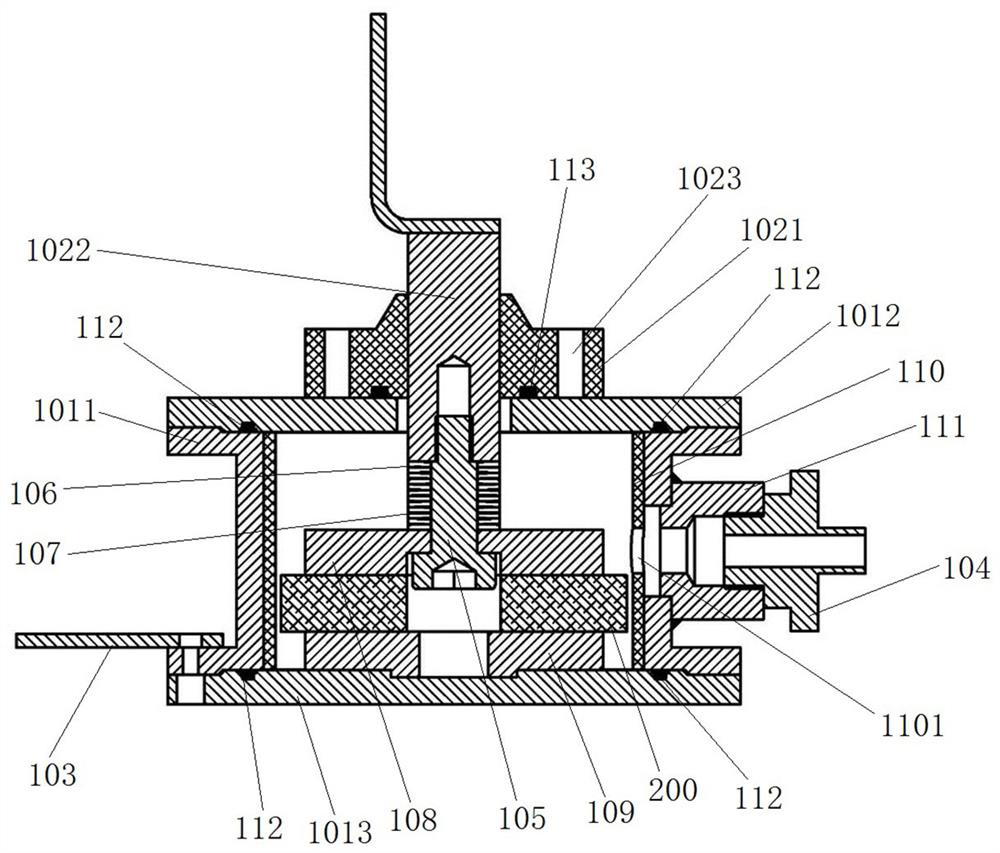

[0042] Such as Figure 1 to Figure 4 As shown, the carbon ceramic linear resistor monolithic insulation test tool (hereinafter referred to as the test tool) provides the required gas environment and pre-tightening force for the insulation performance test of the resistance monolithic 200, and the gas environment and pre-tightening force can be adjusted Change. The resistor monolith 200 here is a carbon ceramic linear resistor monolith.

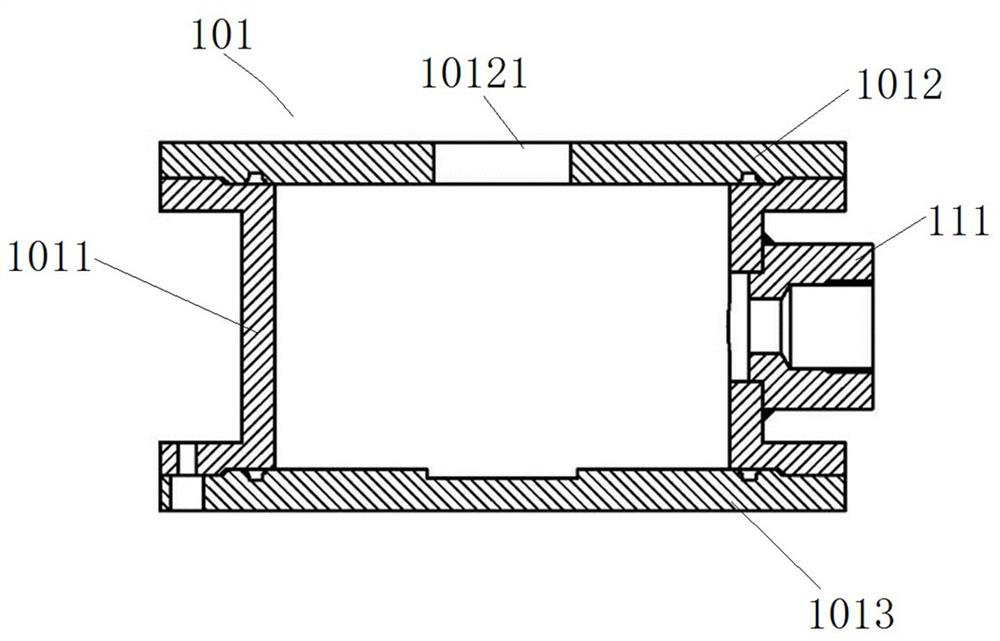

[0043]The test tooling includes a cavity 101, the cavity 101 extends up and down, the cavity 101 includes a cylinder 1011 in the middle, an upper cover 1012 above and a lower cover 1013 below, the cylinder 1011 extends up and down and has an inner cavity in the middle, the cylinder 1011 There are flanges on the upper and lower sides, the upper cover 1012 is fixed on the top of the cylinder 1011 by bolts, and the lower cover 1013 is fixed on the bottom of the cylinder 1011 by bolts. There is a closed air chamber inside the cavity 101 , and th...

Embodiment 1

[0066] In Embodiment 1, the main body of the cavity includes a cylinder and a lower cover that are assembled separately. In this embodiment, the cylinder body and the lower cover can be of an integral structure, and the shape of the main part in the cavity can be changed, such as a square shape.

specific Embodiment 3

[0068] In Embodiment 1, the insulator in the upper connection terminal is provided with screw holes, and is installed on the upper cover by means of screw fixing. In this embodiment, the insulator can be an insulating sleeve, which is fixed on the outside of the conductor, and the insulating sleeve is adapted to be worn in the hole of the copper rod. In order to improve the sealing performance, a sealing ring can be installed on the outer peripheral surface of the insulating sleeve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com