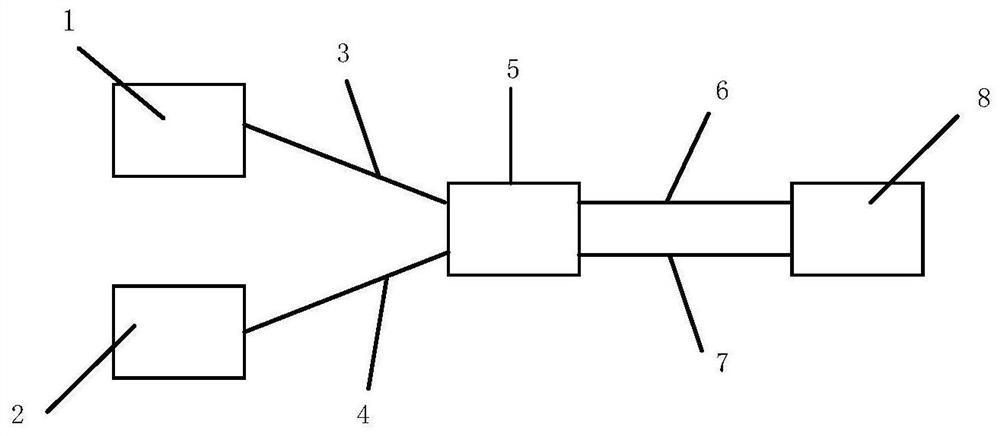

Double-helix planar waveguide magnetic field sensor and manufacturing method thereof

A magnetic field sensor and planar waveguide technology, which is applied to the size/direction of the magnetic field, the optical waveguide light guide, and the use of magneto-optical equipment for magnetic field measurement, etc. Enlarging the phase difference and overcoming the effect of the device being easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

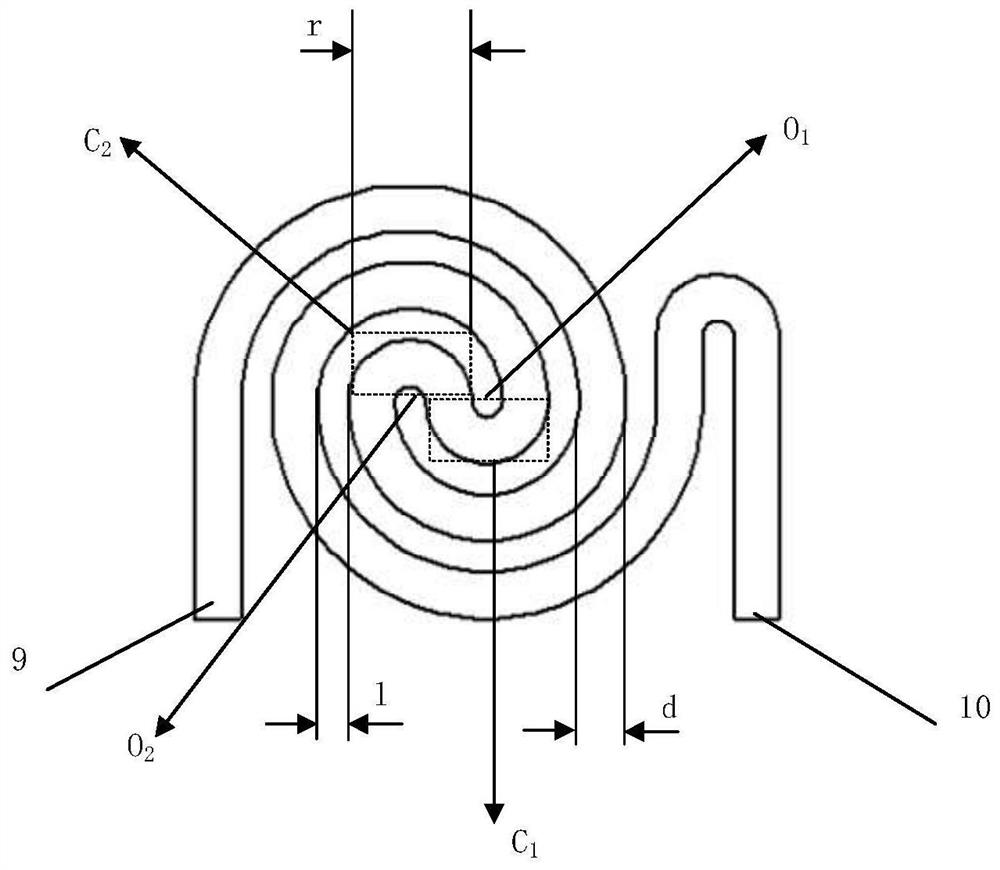

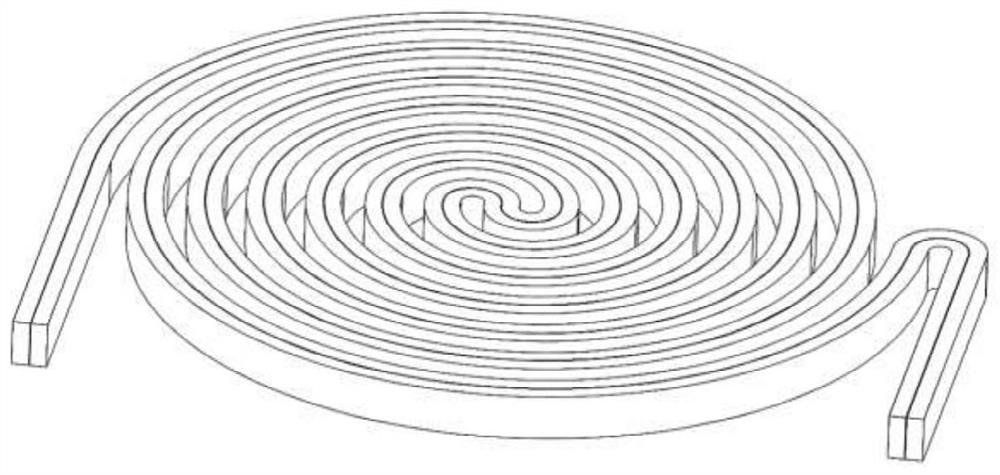

[0024] The present invention will be further described below in conjunction with accompanying drawing and example. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

[0025] The invention adopts two-photon femtosecond laser direct writing technology, according to the refractive index of the material and the geometric shape of the disc waveguide structure, a 3D printing model of the double helical planar waveguide structure is established, the cross section of which is rectangular, and printed on the glass substrate first The first material is the right rectangle in the rectangular cross-section, and the length of the part in contact with the glass substrate is half of the height. After printing, the excess material is cleaned, and the second material is printed as a rectangle by using the two-photon laser direct writing device again. The left side of the cross-sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com