A chemically assisted superabrasive metal bond grinding wheel sharpening device

A metal bond and superabrasive technology, which is applied in the direction of abrasive surface adjustment devices, grinding/polishing safety devices, metal processing equipment, etc., can solve the problems of poor grinding effect, unsuitable coarse-grained grinding wheel dressing, etc., and achieve effective Good for industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

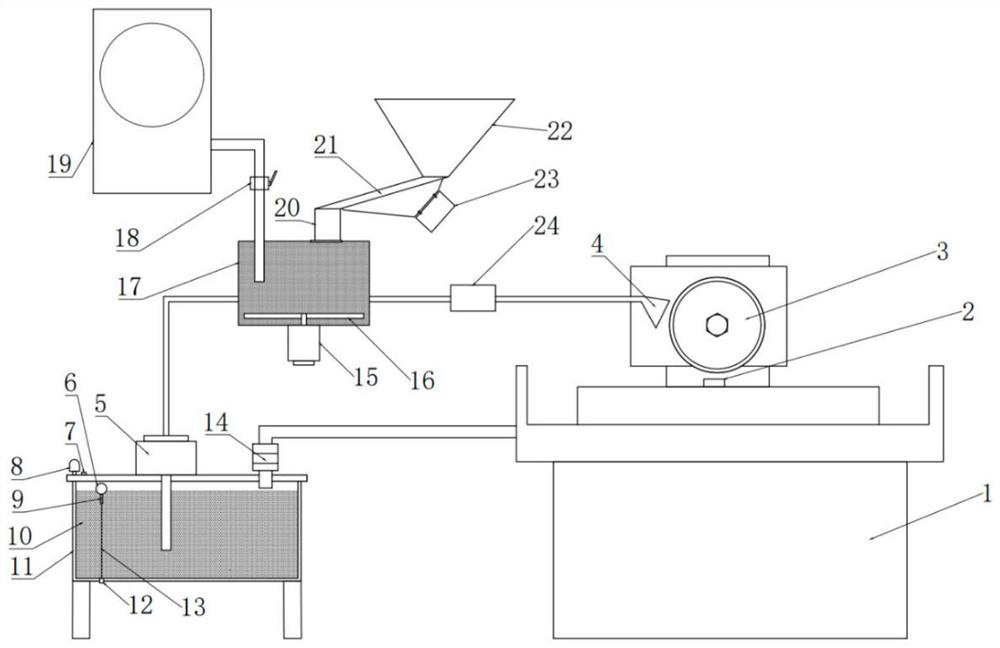

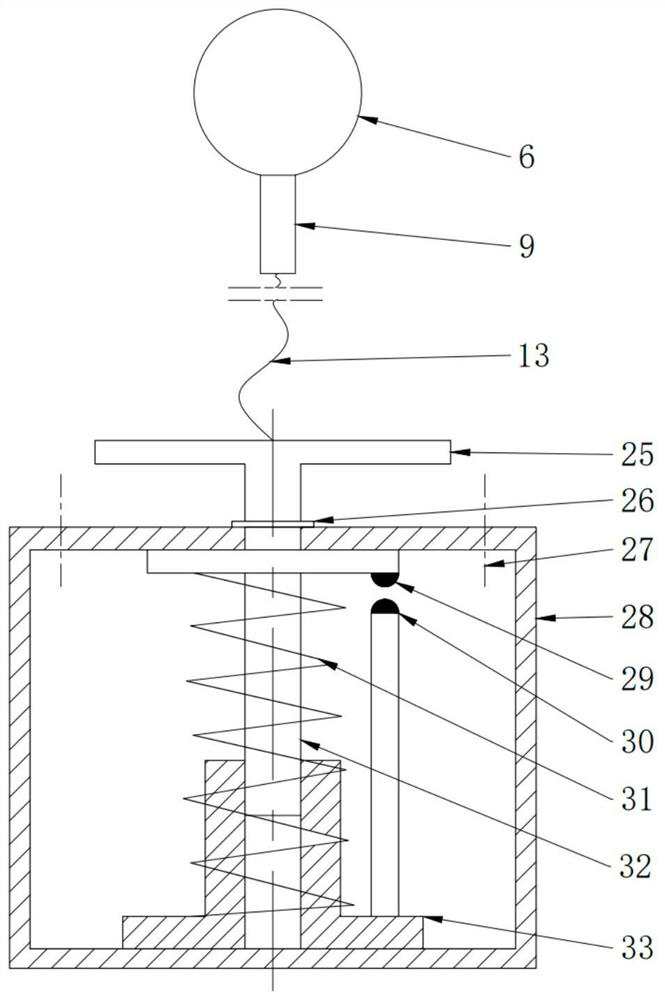

[0022] refer to figure 1 and figure 2 , a chemically assisted superhard abrasive metal bond grinding wheel sharpening device, comprising a grinding machine 1, a grinding fluid injection device, a grinding fluid mixing and stirring device, a grinding fluid circulating filtering device and a grinding fluid shortage alarm device. The cutting fluid spraying device sprays the grinding fluid on the surface of the grinding wheel through the nozzle through the pressurized pump; the grinding fluid mixing and stirring device quantitatively adds the oxidant to the grinding fluid and fully mixes the oxidant and the grinding fluid; the grinding fluid The liquid circulation filter device circulates the grinding fluid during the grinding process and filters out the impurities in the grinding fluid after grinding; the grinding fluid shortage alarm device will drive the grinding flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com