Conveying device in soft tissue production line and conveying method

A conveying device and production line technology, which is applied in the field of hygienic product conveying, can solve problems such as untimely packaging, production shutdown and maintenance, and material blockage, so as to avoid shutdown and production shutdown and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

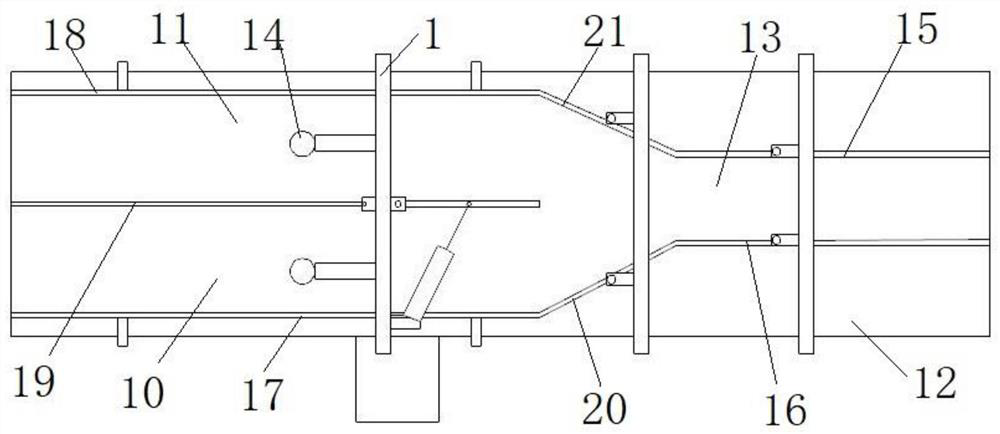

[0031]Such asFigure 1 to 3 As shown, in order to provide two shunt delivery channels, the detecting mechanism of the present embodiment includes an infrared sensor 14 disposed in a shunt delivery channel feed end. Specifically, the first infrared sensor is provided at the feed end of the first shunt delivery passage, and the second infrared sensor is provided in the feed end of the second split delivery passage, and the two infrared sensors are used to detect respective shunt delivery. Whether it appears in the channel. Of course, only an infrared sensor can also be provided only on the feed end of the first shunt delivery passage. When the first infrared sensor detects the blocking of the first shunt passage, the channel can be switched through the channel switching mechanism so that the soft paper towel passes the second Diversion conveying channels are delivered, and when the first infrared sensor is not detected in the first shunt passage, the soft paper towel can be transported...

Embodiment 2

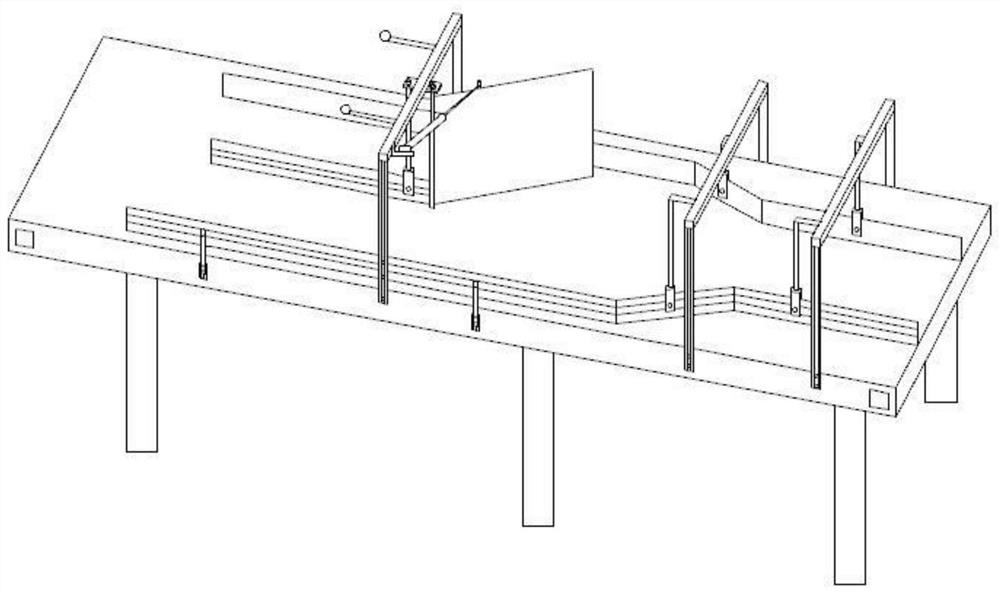

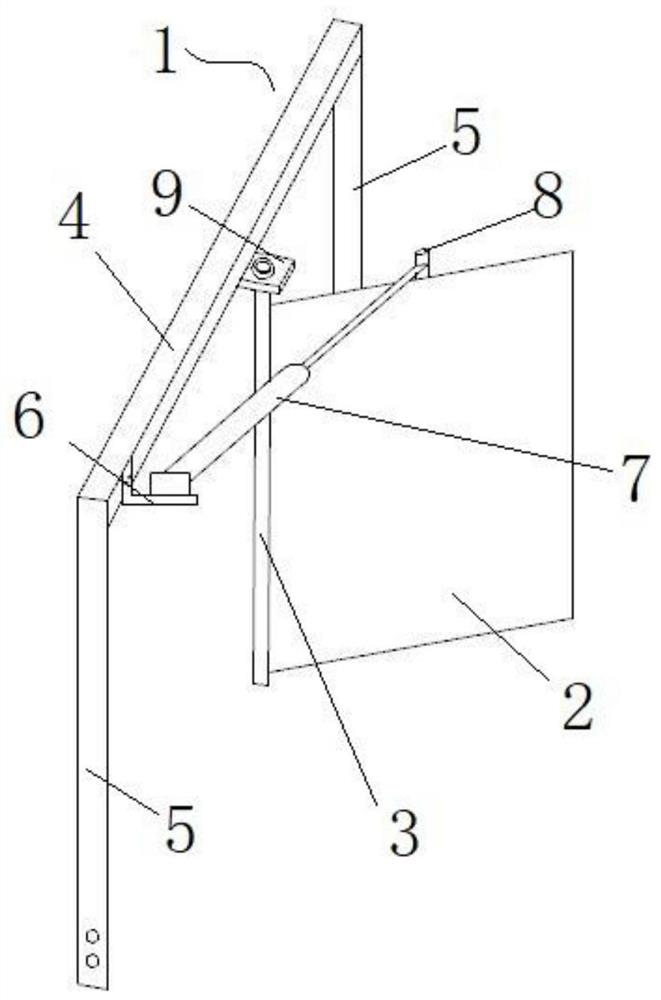

[0045]Such asFigure 4 to 6As shown, the present embodiment differs from the first embodiment in that the conveying platform includes a first conveying platform 26 and a second conveying platform, and the main delivery channel is disposed on the first conveying platform, and the shunt delivery channel is disposed on the second conveying platform. The first conveying platform is coupled to the second conveying platform through the conduit pressure plate 22. Adjust the two transport platforms with the guide press plate, and achieve better conveying of soft paper towels after slitting.

[0046]In this embodiment, the conveying device further includes an adjustment mechanism for adjusting the pitch between the guide plate and the first conveying platform and the second transport platform. The adjustment mechanism is provided to facilitate the adjustment of the distance between the transfer plates to transport the plane of the conveying platform to facilitate the delivery of the soft paper t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com