Ring spinning machine and method for operating spinning position of a spinning machine

A ring spinning machine and ring spinning technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc. It can solve problems such as the inability of the yarn guide to move up and down and difficulty in doffing. Achieve fewer thread defects, high yarn evenness, and high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

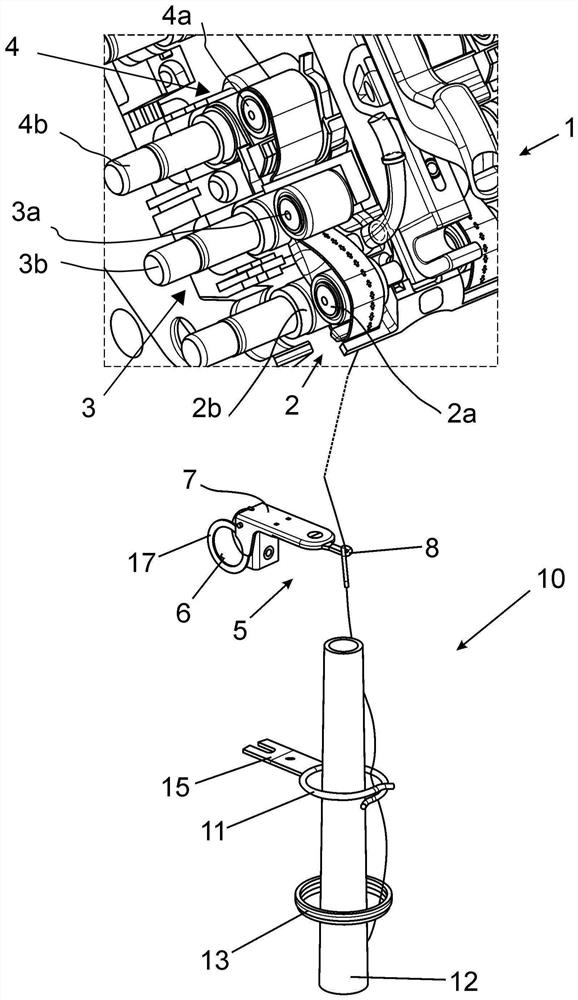

[0054] figure 1 The drafting device 1 of the spinning position of a ring spinning machine with a plurality of centrally driven Spinning bit. The main components of the spinning position are the drafting device 1 and the spindle for accommodating the tube 12 .

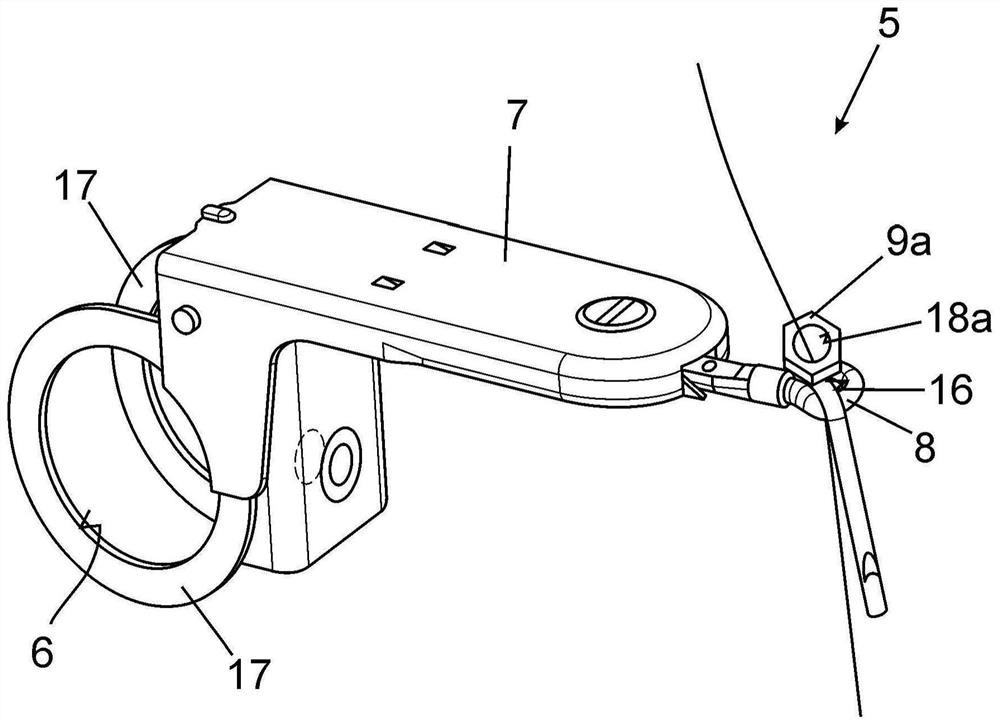

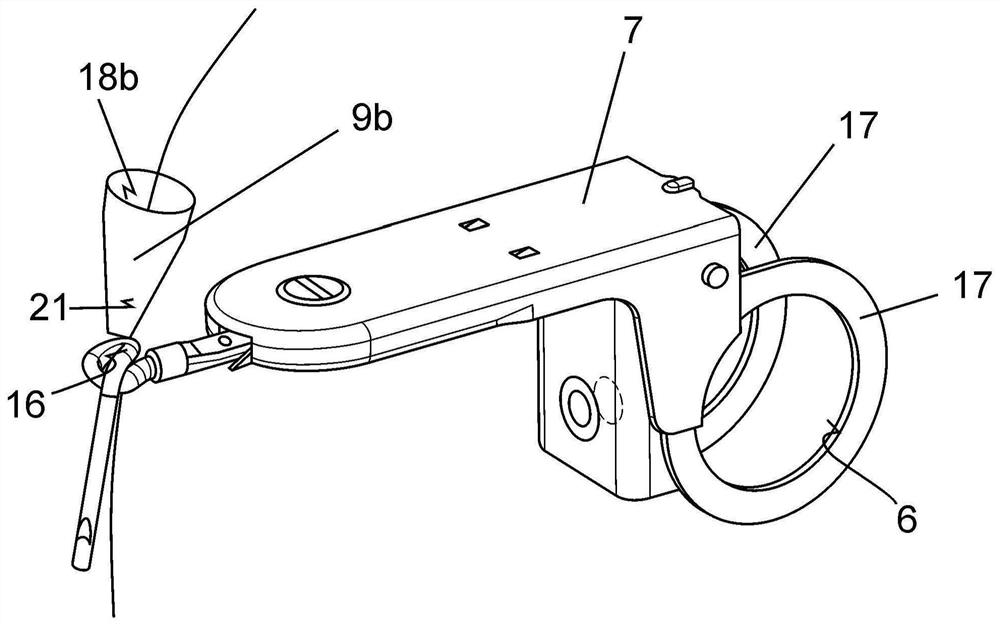

[0055] In the illustrated embodiment, the drafting device 1 has four pairs of rollers, namely, a pair of input rollers not shown, a pair of intermediate rollers 4, a pair of output rollers 3 and a pair of delivery rollers 2 of a compacting apparatus. . Roller pairs 2, 3, 4 are composed of upper rollers 2a, 3a, 4a and lower rollers 2b, 3b, 4b respectively. Thus, the middle roller pair 4 consists of a middle top roller 4a and a middle bottom roller 4b. The middle top roller 4a and the middle bottom roller 4b are respectively wound by draft belts. The output roller pair 3 has an output top roller 3a and an output bottom roller 3b forming a nip line on its contact line. The conveyor roller pair 2 of the agglomeration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com