An intelligent anti-tilt correction device and construction method for strip-based brick walls of cultural relic buildings

A construction and strip-based technology, applied in construction, building maintenance, protection devices, etc., can solve problems such as lack of intelligent rectification function, wall tilt, and walls with a large length cannot be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

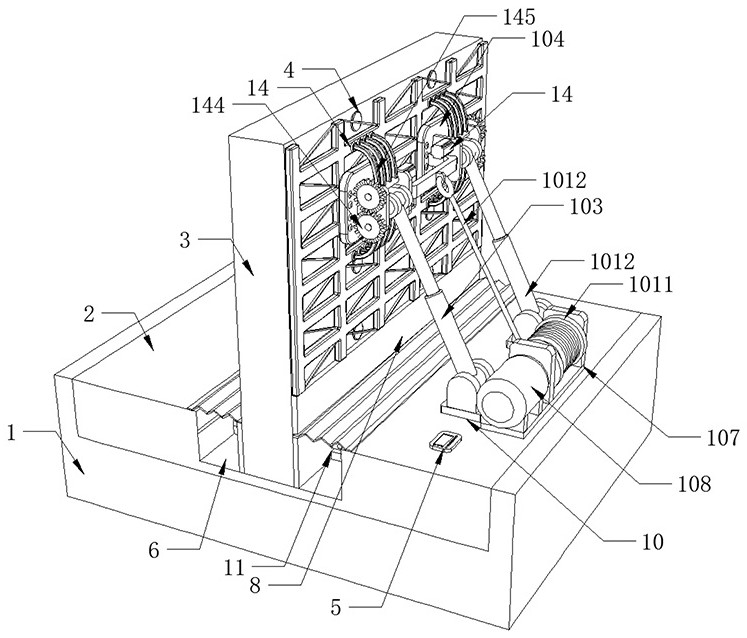

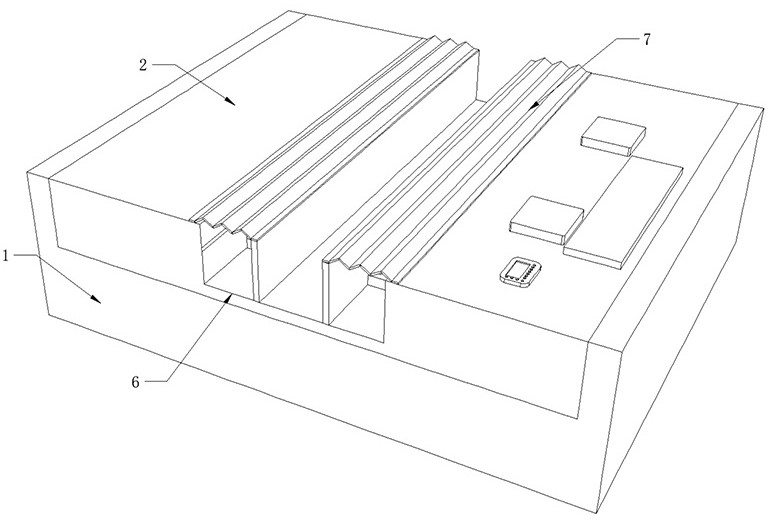

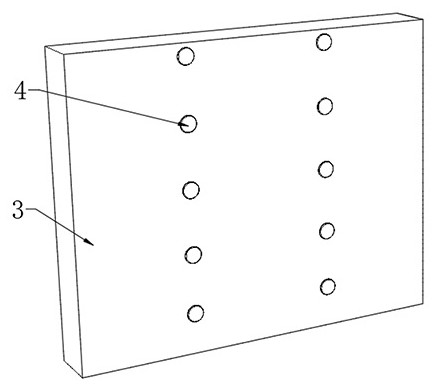

[0037] In the specific implementation process, please refer to the figure 1 , figure 2 , image 3 , Figure 4 with Figure 11, the intelligent anti-tilt correction device for the strip-based brick wall of a cultural relic building, including land 1, foundation body 2, wall body 3, compressive stress sheet 4 and MCU module 5, the top of land 1 is poured with foundation body 2, and foundation body 2 is close to the top An installation groove 6 is provided, and the upper surface of the installation groove 6 is located on the upper surface of the wall body 3. A cover seam plate 7 is provided to facilitate cleaning or maintenance of the shock absorbing mechanism 11 on the inner wall of the installation groove 6, and the bottom of the inner wall of the installation groove 6 is fixed. The wall body 3 is connected, and the foundation beam 8 is fixedly connected to the top side of the foundation body 2. In this embodiment, a prefabricated reinforced concrete baffle is used as the f...

Embodiment 2

[0053] see Figure 11 The difference between this embodiment and Embodiment 1 is that the two sides of the wall body 3 are symmetrically equipped with a foundation beam 8, a strengthening mechanism 9, an anti-deformation mechanism 10 and a stretching mechanism 14. Selective installation is carried out according to the damaged condition, and double-sided support is carried out to correct and strengthen the wall body 3.

[0054] Working principle: By installing an intelligent anti-shock device on the side of the wall body 3 close to the room, the damage to the original building is small, and the external appearance of the cultural relic wall building is not affected. The foundation beam 8 strengthens the connection between the wall body 3 and the outer surface of the foundation body 2, increases the overall performance of the ancient building, can enhance the stability of the building, and reduces vibration; When an earthquake occurs, the surface of the wall body 3 is deformed ...

Embodiment 3

[0057] When the wall body 3 is an inclined wall with a length less than 3 meters, the device is installed on both sides of the wall body 3 and the bottom of the foundation body (2), and the external device is fixedly installed at a reasonable position on the wall body to provide positioning and anti-inversion The role of the hydraulic cylinder (103) of the inner device is driven, the anti-deformation mechanism and the stretching mechanism (14) run simultaneously, the connecting plate (104) and the strengthening mechanism (9) are lifted, the wall body 3 is lifted, and the stretching mechanism (14) is simultaneously The direction of rotation increases the contact surface between the outsourcing steel frame (91) and the wall body 3, and drives the wall body 3 to rotate and lift, so that the wall body 3 resets according to the operating direction of the stretching mechanism (14) and the strengthening mechanism (9). By running the anti-deformation mechanism, the invention can restor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com