Divergent cooling air film hole distribution structure of supersonic turbine blade

A technology of divergent cooling and turbine blades, applied in the direction of blade support components, engine components, machines/engines, etc., can solve the problems of easy deformation and ablation of the divergent cooling layer, achieve simple and fast processing, reduce usage, and ensure The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

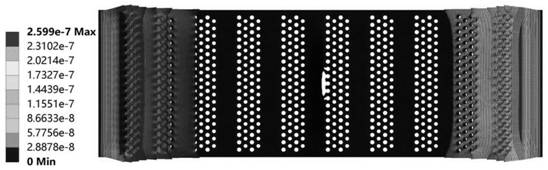

[0040] Example 1: Periodic zigzag air film hole distribution model

[0041] Such as figure 2 As shown, the distribution of air film holes on the divergent cooling layer in this embodiment includes a dense area and an array structure area. The dense area is located at one end of the divergent cooling layer, and the rest of the area on the divergent cooling layer except the dense area is an array structure area.

[0042] The array structure area is arranged in a periodic zigzag array, specifically: the air film holes are distributed in a periodic zigzag band along the longitudinal direction of the divergent cooling layer, and each zigzag band is composed of a number of air hole units arranged in an equilateral triangle. A pore unit is composed of 6 air film holes, the distance between adjacent air film holes is 0.5 mm, the connection line of the center of the 6 air film holes forms an equilateral triangle, and one side of the triangle of each air pore unit on a zigzag belt is l...

Embodiment 2

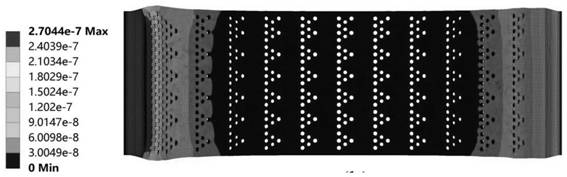

[0046] Embodiment 2: Periodic prismatic air film hole distribution model

[0047] Such as image 3 As shown, the distribution of air film holes on the divergent cooling layer in this embodiment includes a dense area and an array structure area. The dense area is located at one end of the divergent cooling layer, and the rest of the area on the divergent cooling layer except the dense area is an array structure area.

[0048] The array structure area is arranged in the form of a periodic prism array, specifically: the air film holes are distributed in a periodic prism along the longitudinal direction of the divergent cooling layer, the center distances of adjacent prisms are the same, and adjacent rows of prisms are arranged alternately; A prism is made up of 4 gas film holes, and the center line of the 4 gas film holes forms a prism, and the distance between adjacent gas film holes is 0.5 mm. The distance between phase prisms is 0.8 millimeters, and the diameter of air film h...

Embodiment 3

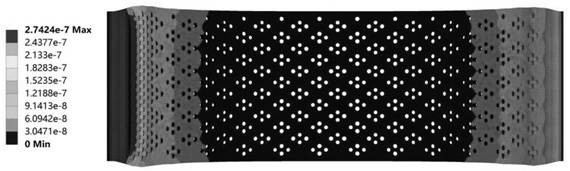

[0052] Example 3: Periodic corrugated gas film hole distribution model

[0053] Such as Figure 4 As shown, the distribution of air film holes on the divergent cooling layer in this embodiment includes a dense area and an array structure area. The dense area is located at one end of the divergent cooling layer, and the rest of the area on the divergent cooling layer except the dense area is an array structure area.

[0054] The array structure area is arranged in the form of a periodic corrugated array, specifically: the gas film holes are distributed in the form of periodic corrugated strips along the longitudinal direction of the divergent cooling layer, and the distance between adjacent corrugated strips is 2.5 mm. Each corrugated strip is composed of two mirrored Each sawtooth belt is composed of a number of air hole units arranged in an equilateral triangle. Each air hole unit is composed of six air film holes. The distance between adjacent air film holes is 0.5 mm. 300 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com