Multi-union lubricating oil pump set easy to maintain and low in pressure pulsation

A low-pressure, easy-to-maintain technology, used in engine lubrication, rotary-piston/oscillating-piston pump components, pumps, etc., to solve problems such as easy loss, long time consumption, and difficulty in operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

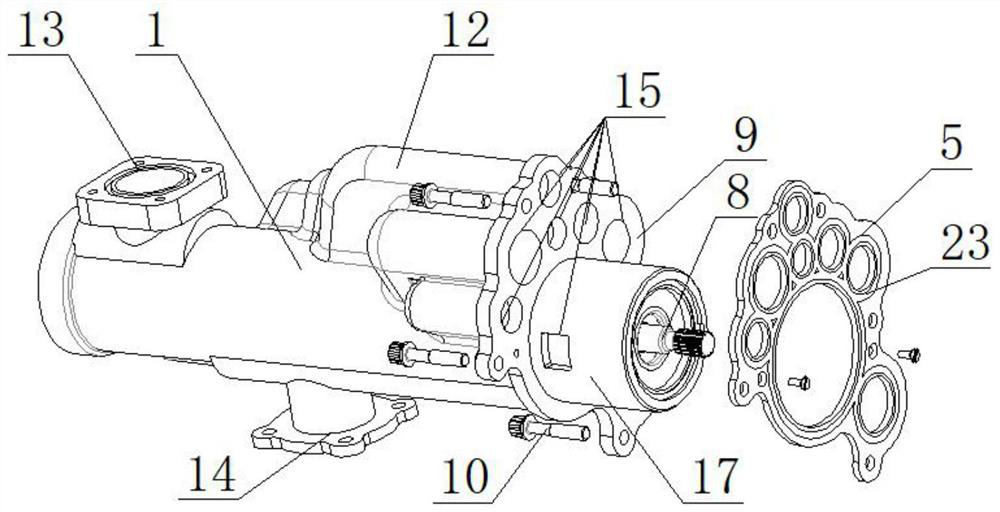

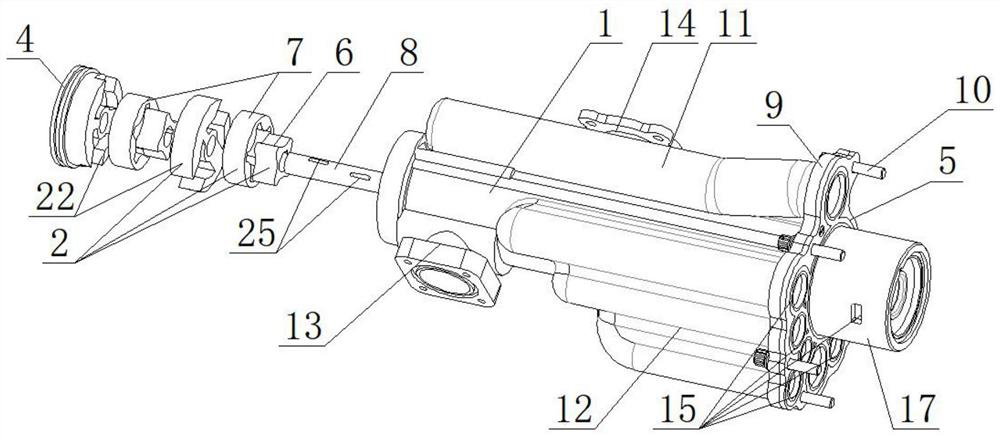

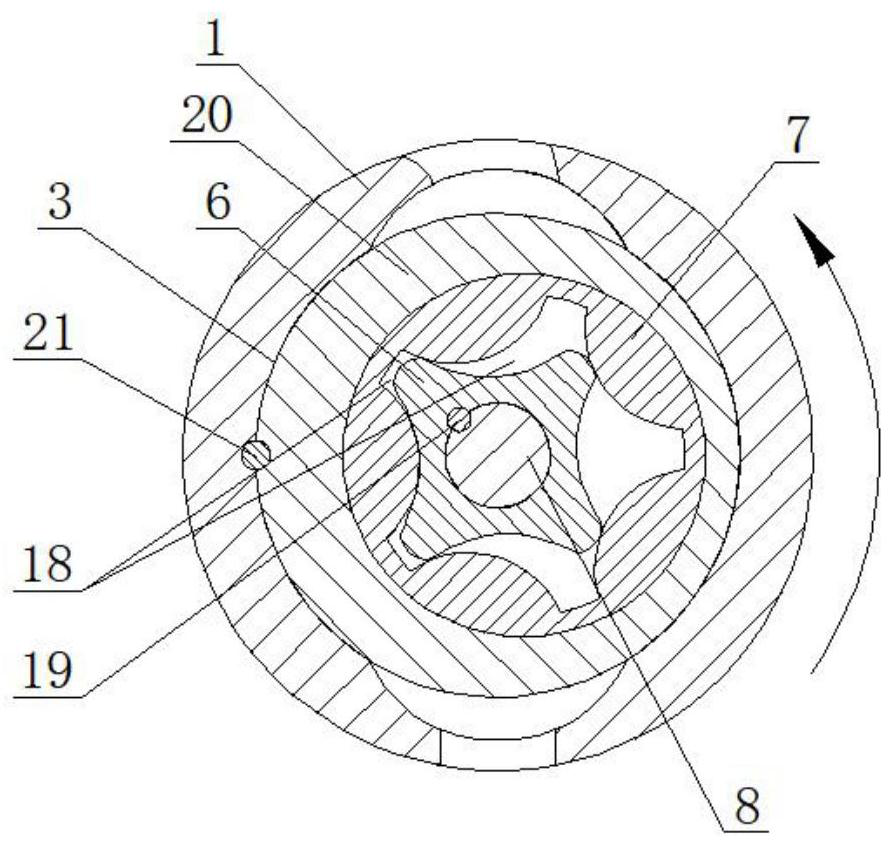

[0024]Seefigure 1 ,figure 2 ,image 3 ,Figure 4 withFigure 5, The present invention includes a pump assembly 1, a grade oil supply pump 2, a multi-stage oil supply pump 3, an end cap 4, and a sealing pad 5, an oil pump 2, an inner rotor 6 of the return pump 3, and the outer rotor 7 passes The same drive shaft 8 is driven, and the oil pump 2 is provided, and the return pump 3 is provided inside the pump set housing 1; the pump assembly 1 is fixed to the left side 4, and the inlet and oil supply pump 2 of several return oil pumps 3 are fixed. The exit is disposed on the flange 9 on the right end surface of the pump group housing, and the flange 9 is opposite the pipe end of the engine attachment machine, and the flange 9 is fixed to the tensioned pad 5, and the flange 9 The engine attachment machine is threaded by the tension screw 10; the oil supply pump 2 includes two pairs of rotors, and the two pairs of rotors are spaced apart in the circumferential direction half a work cycle arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com