Water-cooled flange with embedded circulating water path

A technology of water-cooled flanges and circulating water circuits, which is used in flange connection, pipe heating/cooling, pipe/pipe joint/pipe fittings, etc. lower problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

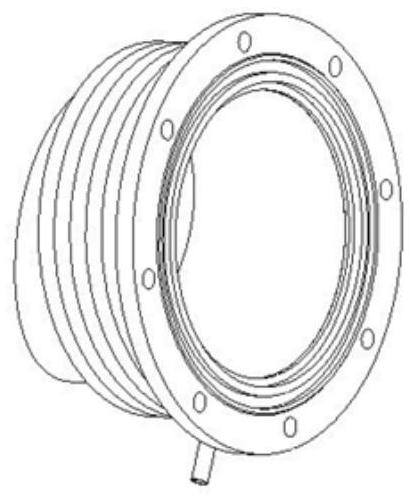

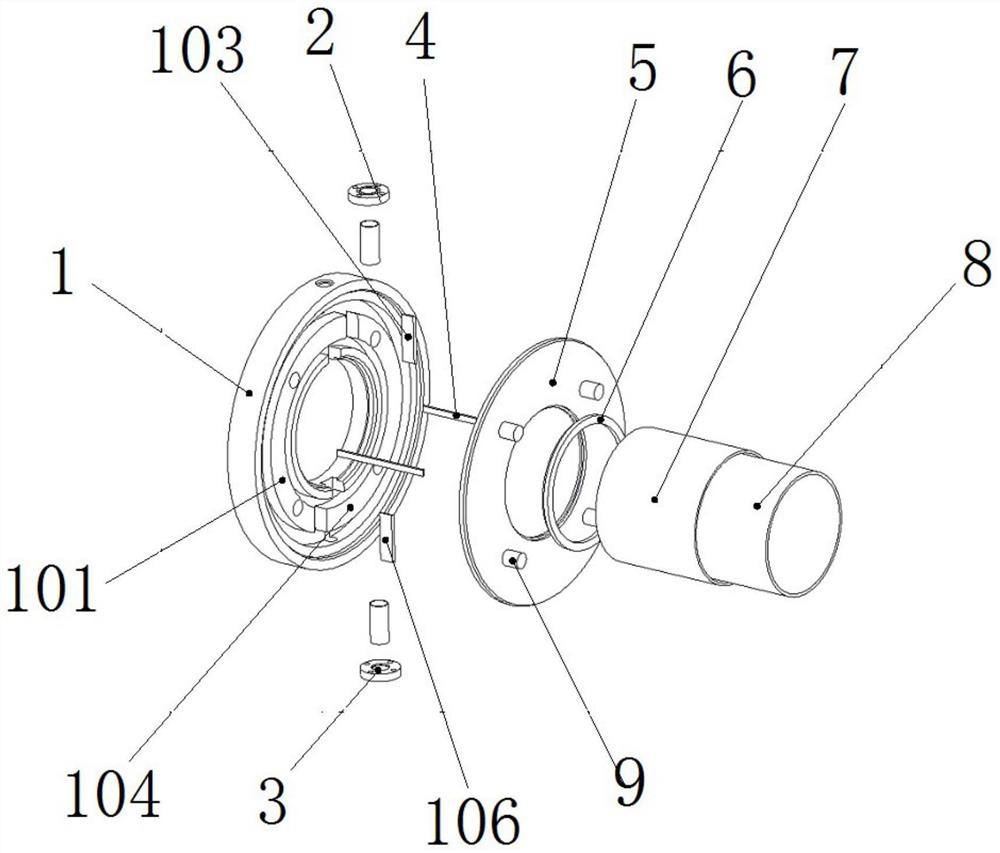

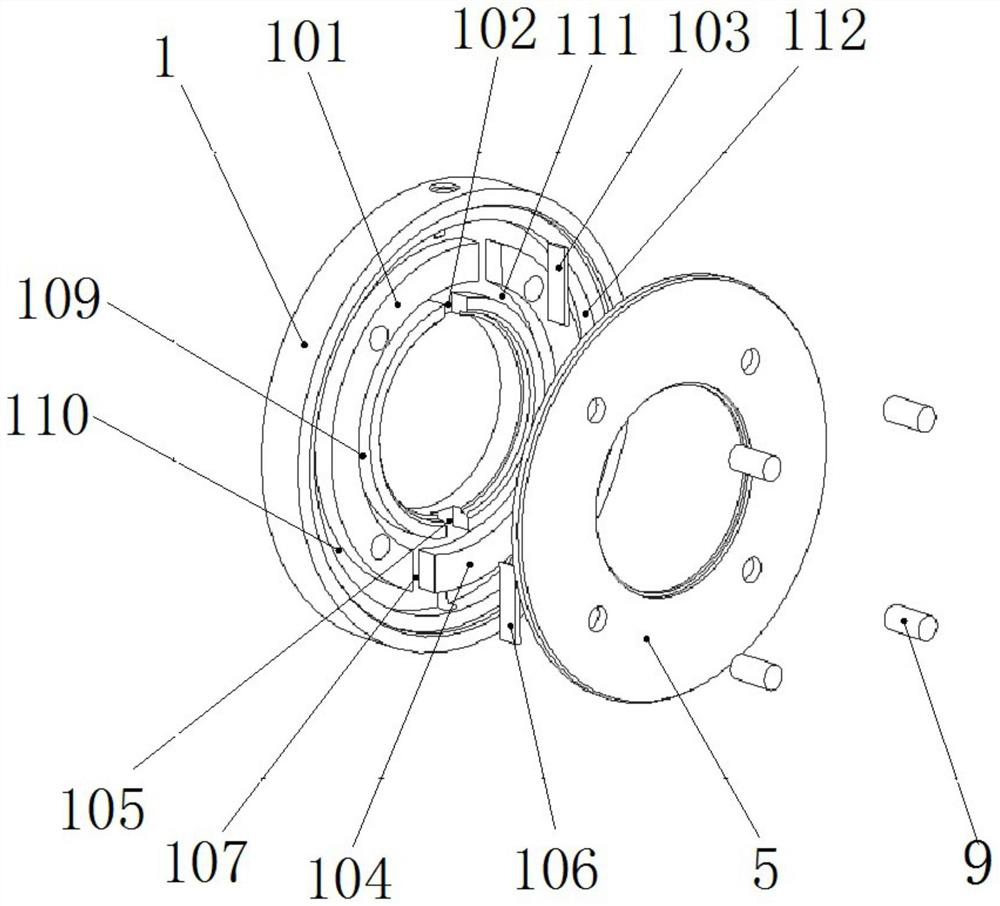

[0033] In order to better understand the purpose, structure and function of the present invention, below in conjunction with appendix Figure 1-7 , understanding of the present invention.

[0034] The present invention uses the form embedded in the vacuum flange to realize the function of directly contacting the heat source to cool down. The structure embedded in the vacuum flange is designed with a circulating cooling water circuit in the middle, and there is a cooling water circuit at the flange port. The water inlet and outlet can realize the circulation of cooling water, and a sealing structure is designed on the end face of the water-cooling flange, which can be used as a link between the vacuum flange and the vacuum tank, and at the same time does not affect the original function of the corresponding vacuum flange.

[0035] The water-cooled flange adopts the form of embedded cooling water circuit, which solves the problem that the local temperature of the vacuum flange i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com