Power device used for garbage compression

A power device and garbage compression technology, which is applied to fluid pressure actuators, fluid pressure actuation system components, servo motors, etc., can solve the problems of large reversing impact, heavy power device weight, and high oil temperature of equipment, and achieve extended Longer service life, avoiding oil pump damage, avoiding the effect of bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

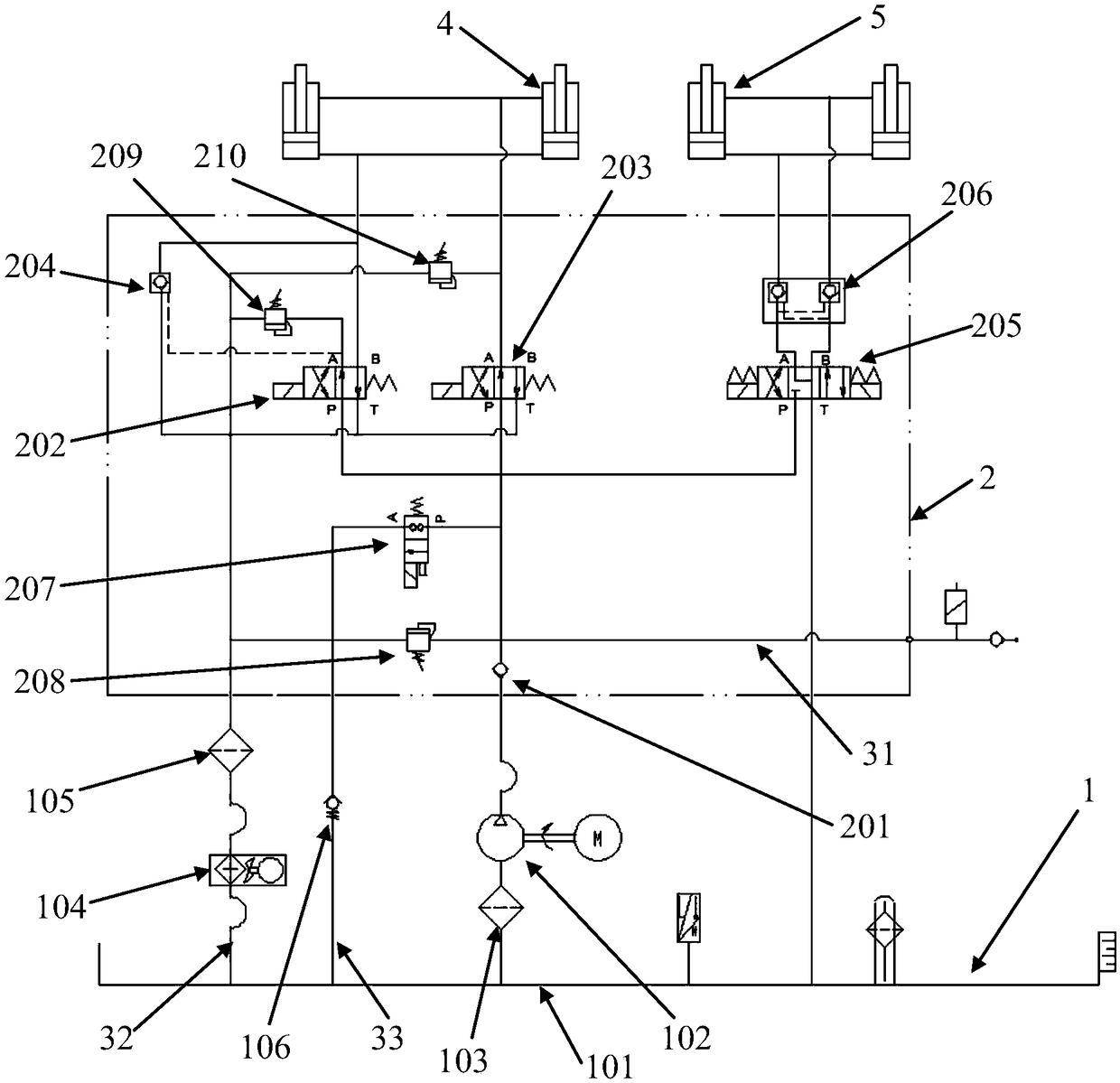

[0020] refer to figure 1 It can be seen that the present invention discloses a power device for garbage compression, including a fuel tank assembly 1, a hydraulic valve group assembly 2 and a power assembly; wherein, the fuel tank assembly 1 includes a fuel tank 101 for carrying hydraulic oil and a communication For the oil pump 102 of the oil tank 101, the hydraulic valve group assembly 2 includes a one-way valve 201, a first two-position four-way solenoid valve 202, a second two-position four-way solenoid valve 203 and a hydraulic control check valve 204, and the one-way valve 201 The inlet of the check valve 201 is connected to the oil outlet of the oil pump 102, and the outlet of the check valve 201 is respectively connected to the P oil port of the first two-position four-way solenoid valve 202 and the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com