Method and device for calibrating flow coefficient of orifice plate by adopting pressure method

A technology of flow coefficient and calibration hole, which is applied in the field of gas flow testing and calibration, and can solve problems such as high pressure, potential safety hazards, and exceeding the acceptable range of the container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

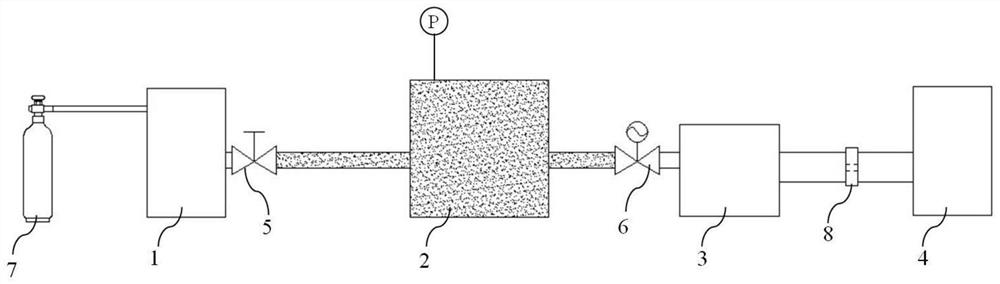

[0034] like figure 1 As shown in the figure, a device for calibrating the flow coefficient of an orifice plate by a pressure method includes a feeding container 1, a feeding pressure-relief tank 2, a pressure-stabilizing tank 3 and a receiving container 4 that are communicated in turn through a vacuum pipeline. The feeding container 1 The outlet is provided with a valve 5, an electric pressure regulating valve 6 is provided between the supply pressure relief tank 2 and the pressure stabilization tank 3, and the orifice plate 8 is arranged in the vacuum pipeline between the pressure stabilization tank 3 and the material receiving container 4. The pressure relief tank 2 is connected with a pressure measuring device.

[0035] The device for calibrating the flow coefficient of the orifice plate by the pressure method further includes a high-pressure gas cylinder 7 which is communicated with the supply container 1 or the supply pressure relief tank 2 .

Embodiment 2

[0037] Based on the device of Embodiment 1, a method for calibrating orifice flow coefficient by pressure method, comprising the following steps:

[0038] (I) Use the standard volume to measure the volume V of the reference area; the reference area is the area between the valve 5 and the electric pressure regulating valve 6, namely figure 1 middle fill area;

[0039] (II) Evacuate the system after the valve 5, start the test after the evacuation is completed, and maintain the temperature T of the system and the test environment during the test 0 constant;

[0040] (Ⅲ) Electric pressure regulating valve to stabilize P K1 , measure Δt 1 Time reference area pressure drop ΔP 1 ;

[0041] (IV) According to the design of different electric pressure regulating valve voltage regulation value P Ki , repeat step (III), measure the corresponding Δt i Time gray area pressure drop ΔP i ;

[0042] (Ⅴ) When the pressure of the supply buffer tank is not enough, use a high-pressure ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com