High-pressure fluid nozzle detection workbench

A technology for testing workbenches and high-pressure fluids. It is used in measuring devices, mechanical parts testing, and machine/structural parts testing. It can solve problems such as affecting production, time-consuming and labor-intensive, and incompatible nozzle models, specifications, and models.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

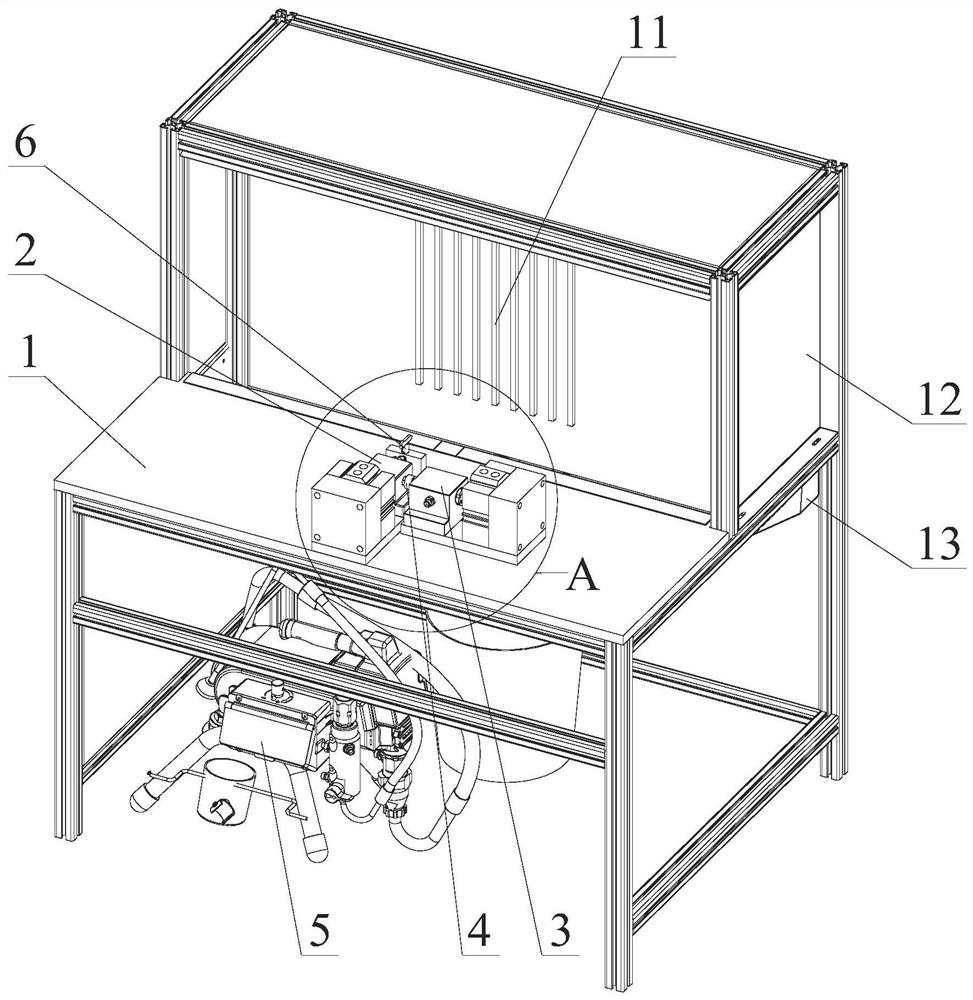

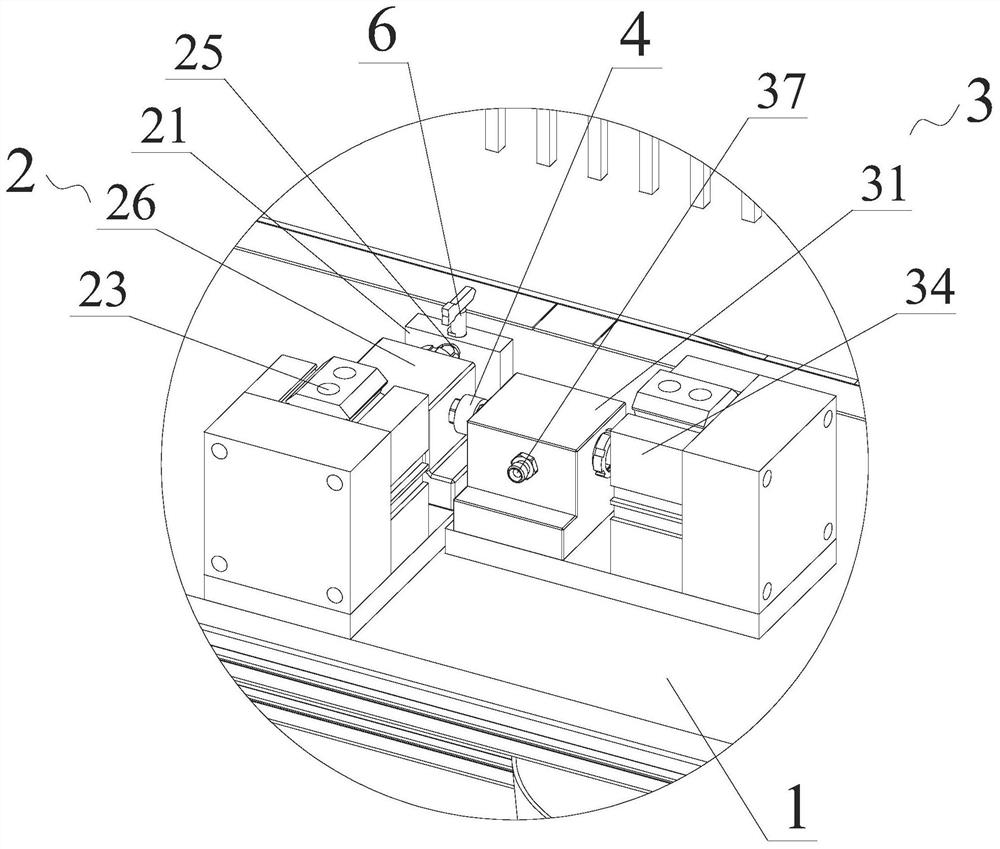

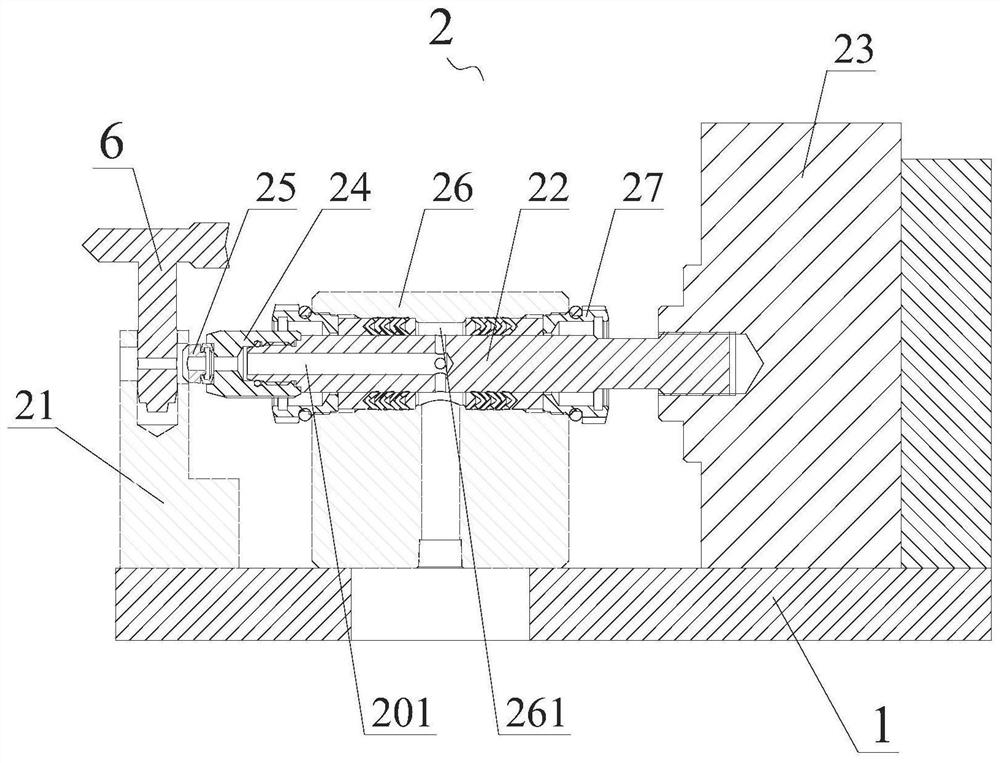

[0026] see Figure 1-4 As shown, a high-pressure fluid nozzle detection workbench includes a detection table 1, and the detection table 1 is provided with a nozzle detection and positioning assembly 2 and a high-pressure fluid on-off assembly 3, and the nozzle detection and positioning assembly 2 is connected to the A fluid delivery joint 4 is provided between the high-pressure fluid on-off components 3, a first fluid channel 201 is provided in the nozzle detection and positioning component 2, and a second fluid that can be controlled on and off is provided inside the high-pressure fluid on-off component 3. Channel 301, the high-pressure fluid on-off assembly 3 is connected to the small sprayer 5 arranged under the detection table 1 through a pipeline, and the nozzle detection and positioning assembly 2 is used to fix and communicate with the no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com