Air control device for continuous tea leaf de-enzyming and carding machine

A greening machine and tea technology, which is applied in tea treatment before extraction, can solve the problems of poor competitiveness of tea quality, cumbersome and laborious adjustment methods, and inability to adjust the wind direction, so as to achieve the effect of improving the color and luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

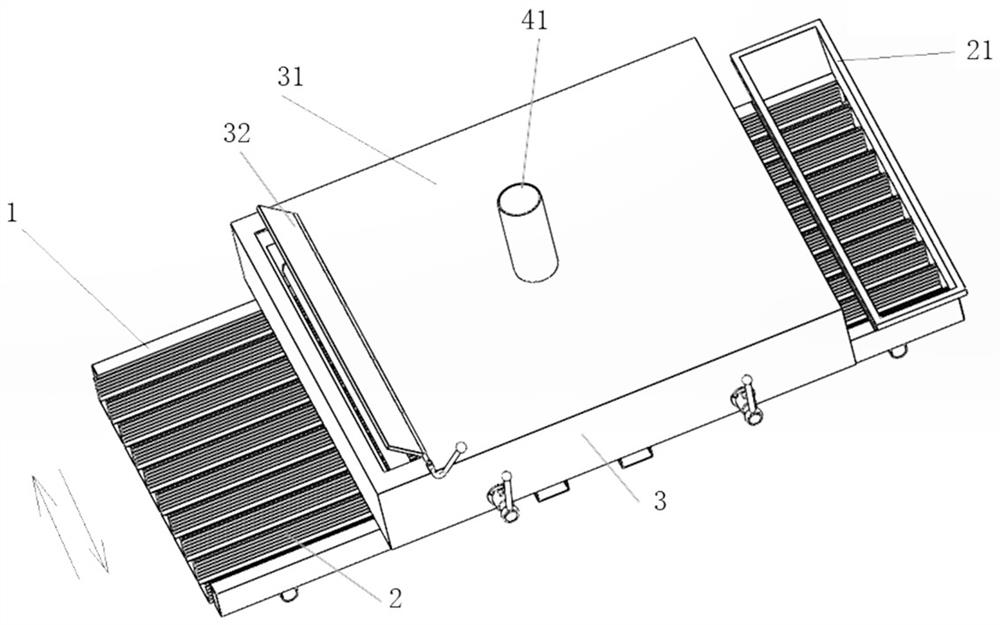

[0038] Such as figure 1 As shown, a wind control device for a continuous tea finishing machine, including a rectangular frame 1 and a pot mechanism, the pot mechanism includes more than four pots 2, and more than four pots 2 along the The length direction of the frame 1 is arranged side by side in the frame 1, one end is the material inlet, and the other end is the material outlet;

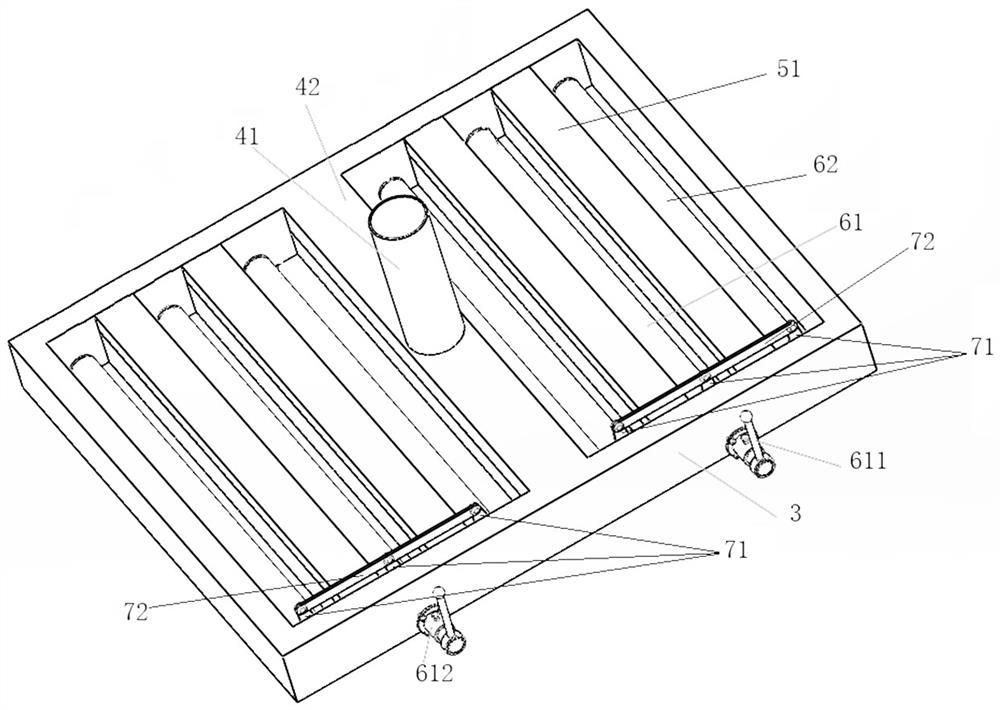

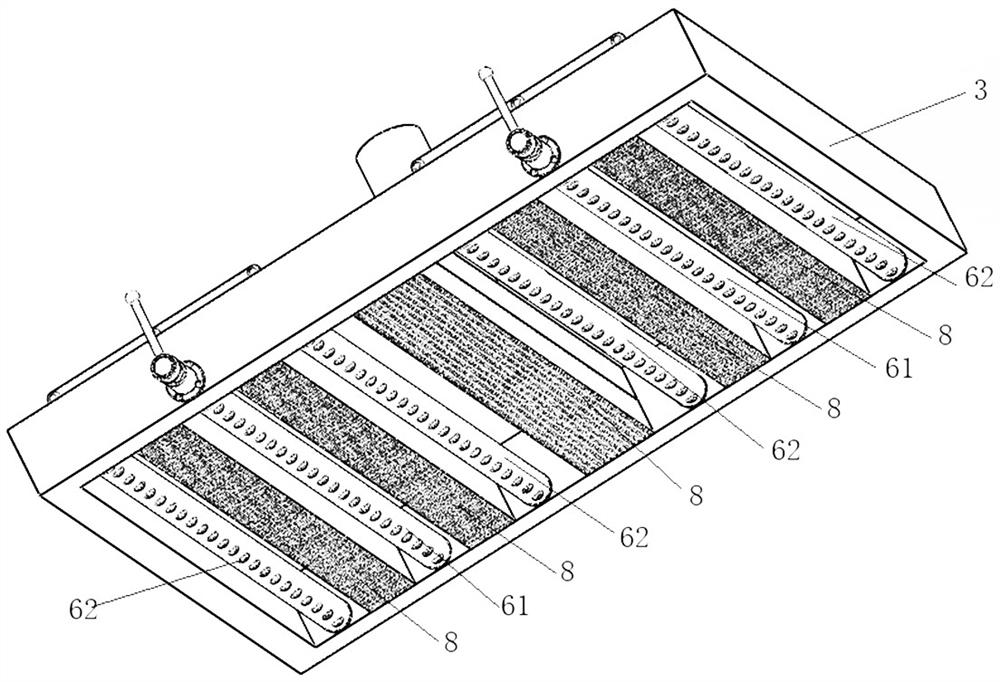

[0039] See Figure 2~3 As shown, it also includes an air control device fixedly installed above the frame 1. The air control device includes an air intake mechanism, a sealed return-shaped air duct 3, and more than two air distribution channels uniformly arranged along the length direction of the return-shaped air duct 3. mechanism, and the upper end of the return-shaped air duct 3 is provided with a cover plate 31 in conjunction with the cover.

[0040] See Figure 4 It is the return-shaped air duct 3.

[0041] The air intake mechanism includes a connected air intake pipe 41 and a rectangular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com