Crystalline self-cooked rice and preparation method thereof

A crystalline, self-cooking technology, used in food ingredients as a fluffing agent, food drying, food science, etc., can solve problems such as loss of nutrients, and achieve the effect of retaining flavor, reducing rehydration time, and shortening the time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

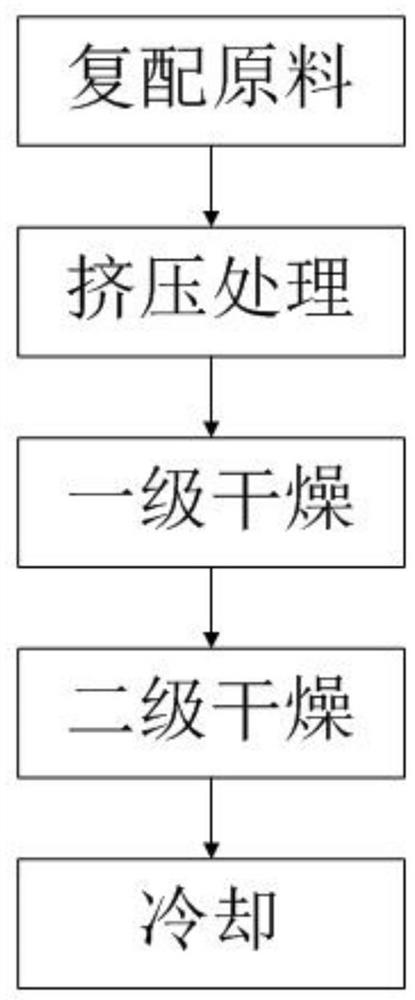

Method used

Image

Examples

Embodiment 1

[0041] S11. Extrude 60 parts of compound raw rice, 20 parts of cornstarch, 15 parts of water, 0.1 part of monoglyceride and 0.1 part of calcium dihydrogen phosphate, and respectively control the temperature of the second zone in the extruder to 50°C , The temperature in the third zone is 88°C, the temperature in the fourth zone is 128°C, the temperature in the fifth zone is 123°C, the temperature in the sixth zone is 108°C, the temperature in the seventh zone is 92°C, and the extrusion process is controlled to be completed within 60s , get prefabricated rice;

[0042] S12, using a fluidized bed dryer to perform primary drying of the prefabricated rice at 70° C., so that the prefabricated rice is completely dispersed;

[0043] S13. The prefabricated rice after the primary drying treatment is subjected to secondary drying at 55°C in a drying box with a dehumidification device, and the moisture content of the product is controlled below 16%;

[0044] S14. Cool the prefabricated ...

Embodiment 2

[0046] S21. Extrude 80 parts of rice, 40 parts of cornstarch, 30 parts of water, 1 part of difatty acid glyceride and 1 part of calcium dihydrogen phosphate for compound raw materials, and respectively control the temperature of the second zone in the extruder to 70°C , The temperature of the third zone is 92°C, the temperature of the fourth zone is 128°C, the temperature of the fifth zone is 127°C, the temperature of the sixth zone is 112°C, the temperature of the seventh zone is 92°C, and the extrusion process is controlled to be completed within 30s , get prefabricated rice;

[0047] S22, using a fluidized bed dryer to perform primary drying of the prefabricated rice at 90°C;

[0048] S23. The prefabricated rice after the primary drying treatment is subjected to secondary drying at 45°C in a drying oven with a dehumidification device, and the moisture content of the product is controlled below 16%;

[0049] S24. Cool the prefabricated rice after the secondary drying treatm...

Embodiment 3

[0051] S31. Extruding 70 parts of compound raw rice, 30 parts of cornstarch, 22 parts of water, 0.5 part of mono- and di-fatty acid glycerides and 0.5 part of calcium dihydrogen phosphate, respectively controlling the temperature of the second zone in the extruder to 60 ℃, the temperature of the third zone is 90 ℃, the temperature of the fourth zone is 130 ℃, the temperature of the fifth zone is 125 ℃, the temperature of the sixth zone is 110 ℃, the temperature of the seventh zone is 90 ℃, and the extrusion process is controlled within 50s Finished, get prefabricated rice;

[0052] S32, using a fluidized bed dryer to perform primary drying of the prefabricated rice at 80°C;

[0053] S33. The prefabricated rice after the primary drying treatment is subjected to secondary drying at 50° C. in a drying box with a dehumidification device, and the moisture content of the product is controlled below 16%;

[0054] S34. Cool the prefabricated rice after the secondary drying treatment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com