Deep open-pit mine slope lifting and crushing system

A crushing system and open-pit mine technology, which is applied in open-pit mining, special mining, earth square drilling, etc., and can solve problems such as increasing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached Figure 1-4 The application is described in further detail.

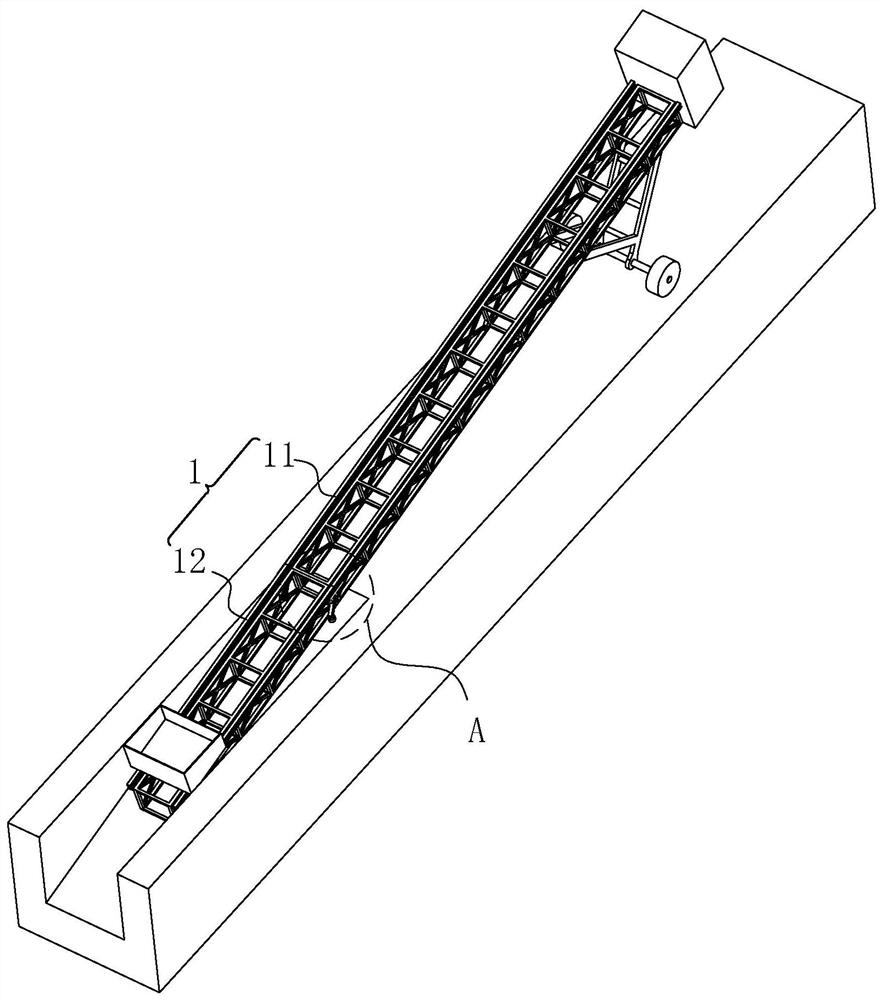

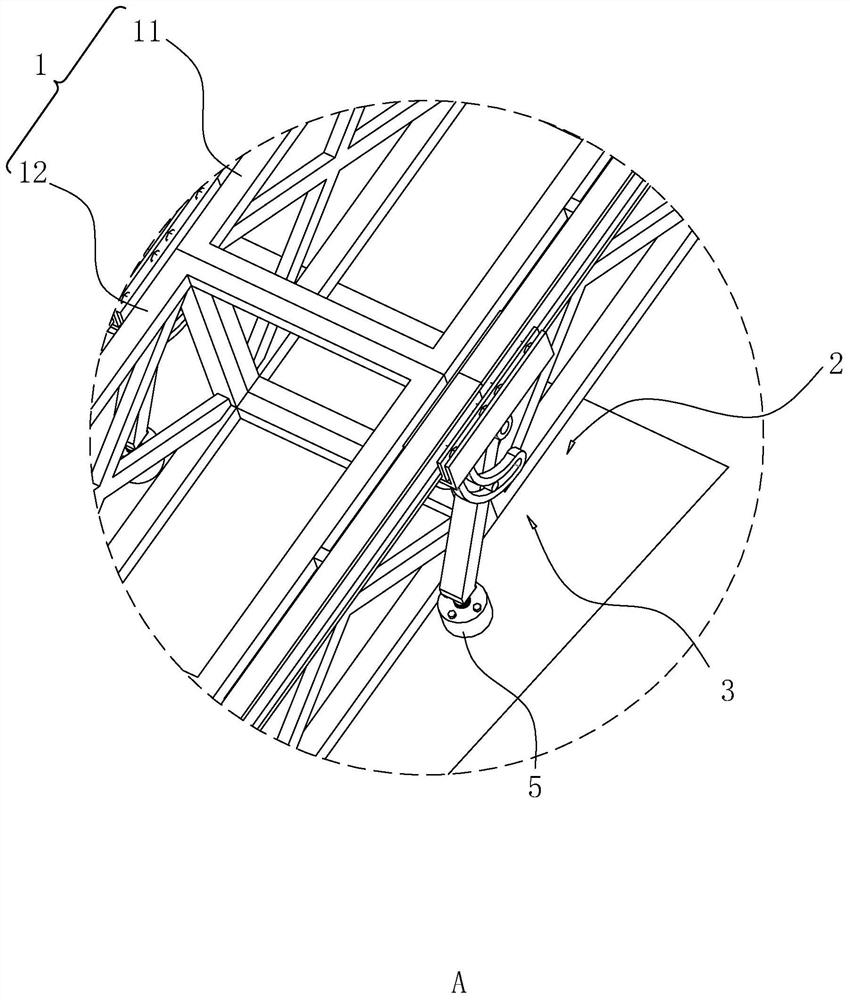

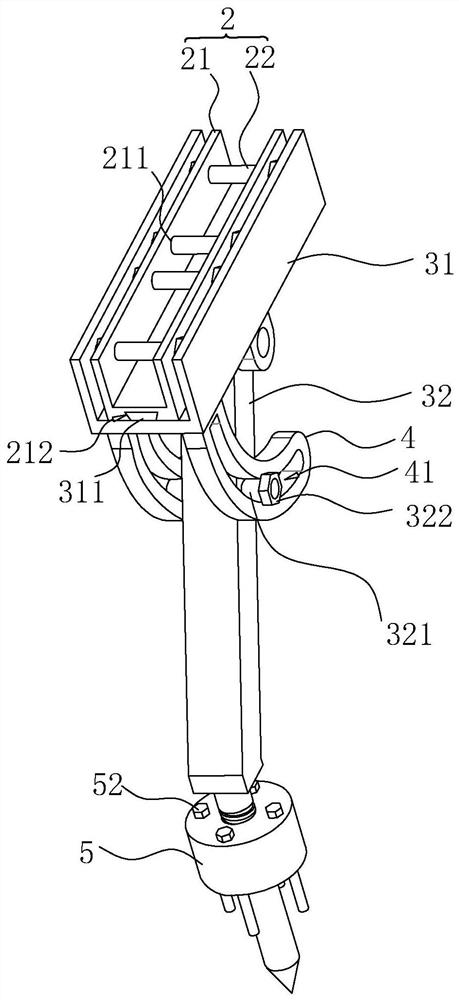

[0037] The embodiment of the present application discloses a slope lifting and crushing system in a deep concave open-pit mine. combine figure 1 and figure 2 , a slope lifting and crushing system for a deep concave open-pit mine, including a track 1 laid on the top of the deep concave open-pit stope and on the slope, the track 1 includes a first slide rail 11 and a second slide rail 12, and the first slide rail 11, One end of the second slide rails 12 close to each other is detachably provided with a connecting assembly 2, and as the depth of the deep concave open-pit stope increases, the relative lengths of the first slide rail 11 and the second slide rail 12 can be changed by adjusting the connecting assembly 2 , to facilitate the lifting of the crushing system to mine deep concave open pits of different depths, reduce the number of times to relocate crushing stations and reins...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap