Coupling

A technology of coupling and semi-coupling, applied in the direction of coupling, elastic coupling, mechanical equipment, etc., can solve the problems of increasing the axial size of the coupling, large axial space, unfavorable transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

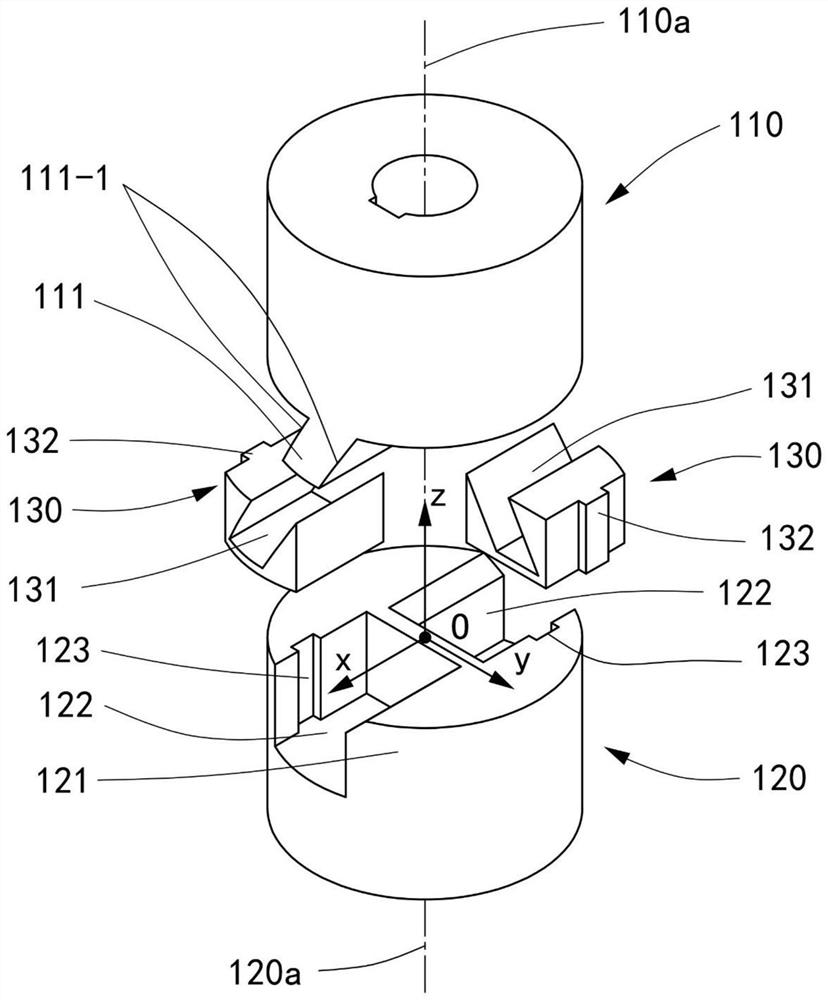

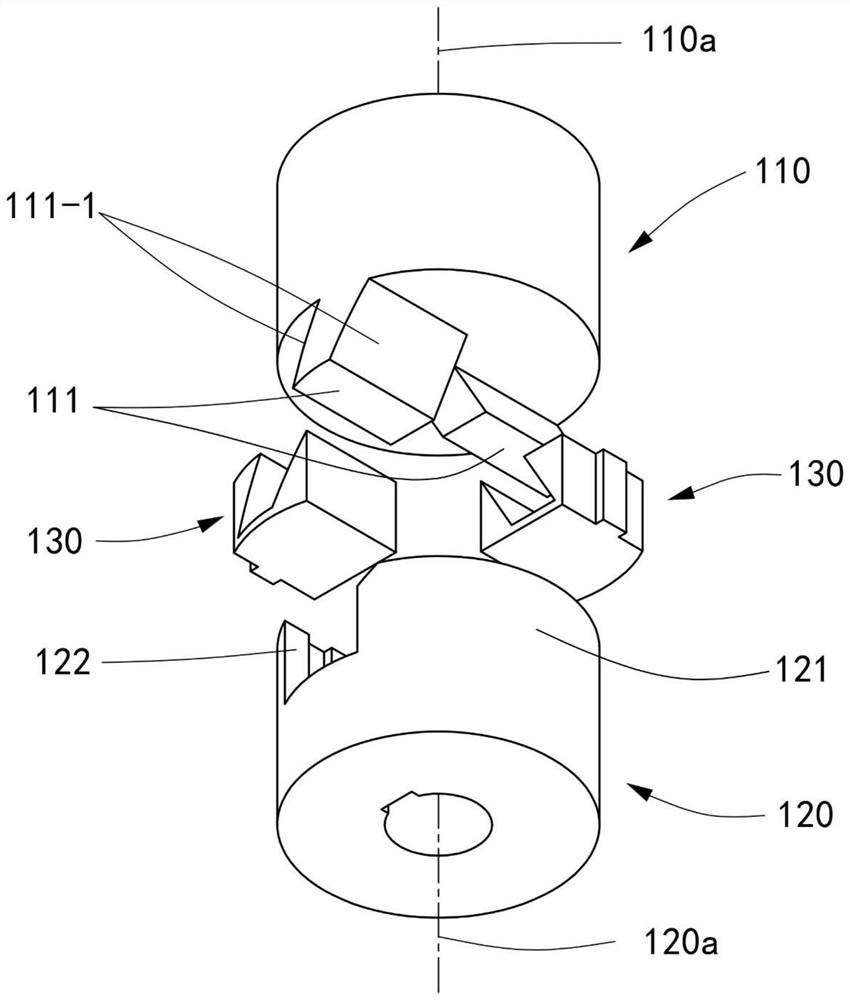

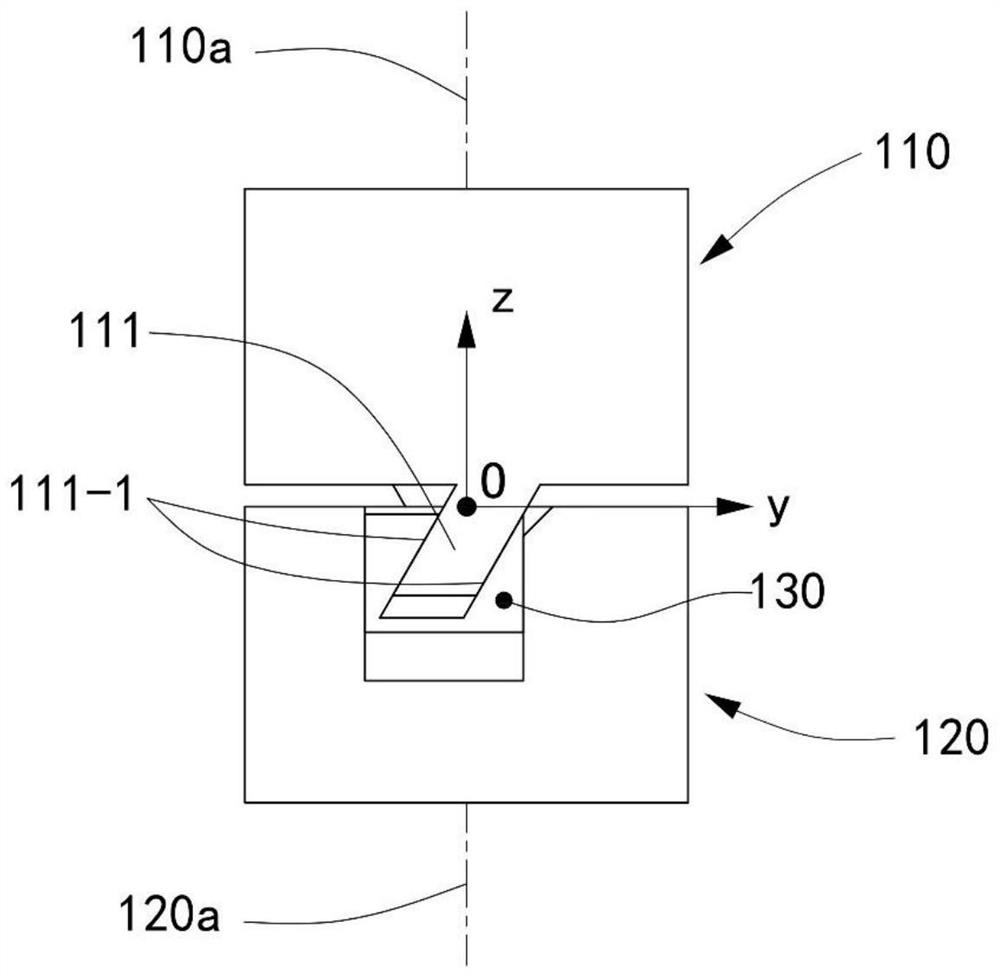

[0023] Such as figure 1 with figure 2 Shown is the coupling provided by the first embodiment of the present invention, including a first half coupling 110 , a second half coupling 120 and an intermediate connecting member 130 connecting the two half couplings 110 and 120 . The intermediate connecting piece 130 can only be slidably connected to the second half-coupling 120 in the axial direction, that is, it can only be slidably connected to the second half-coupling in the axial direction but not relatively rotatable. device 120. At the same time, the intermediate connecting piece 130 connects the second coupling 120 to the first coupling half 110 so that it can move freely in all directions along an inclined plane on the first coupling half 110. plane, and in the following description, unless otherwise specified, "inclined" is interpreted as inclined to a radial plane.

[0024] Here, the rotation axis of the first half-coupling 110 is referred to as the first rotation axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com