Efficient ice making system

A control system and high-efficiency technology, applied in ice making, control/regulation system, ice making, etc., can solve problems such as difficulty in matching engine speed, poor ice making efficiency, energy loss, etc., to avoid energy loss and improve refrigeration efficiency , the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present application will be further described below in combination with specific embodiments.

[0017] In order to make the purpose, technical solutions and advantages of the present application clearer, the present application will be further described in detail below in conjunction with specific embodiments. It should be understood that the specific implementation manners described here are only used to explain the present application, and are not intended to limit the present application.

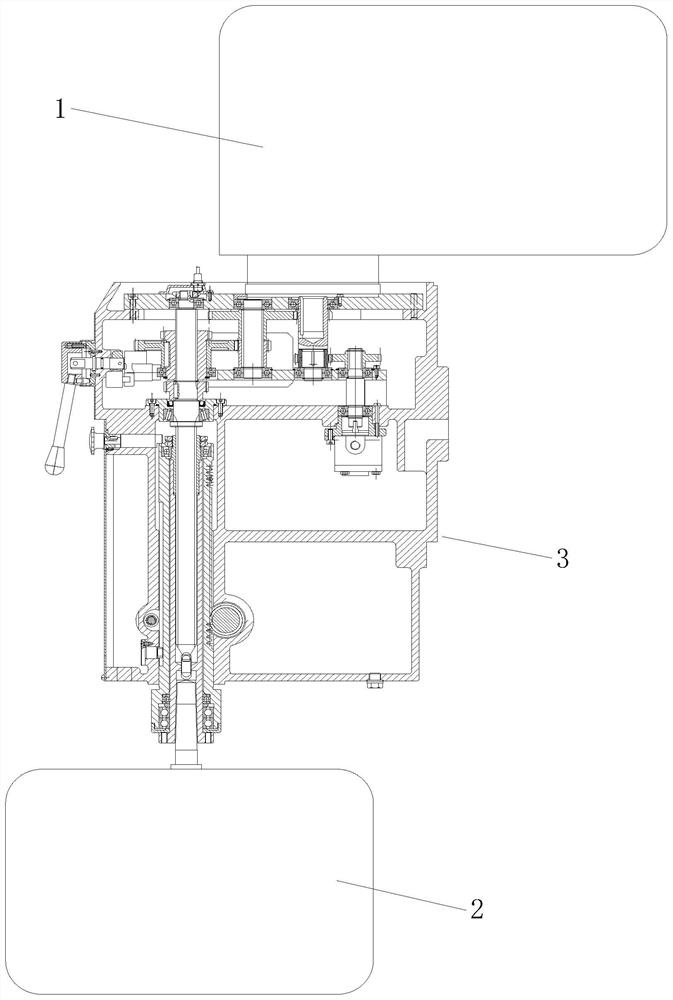

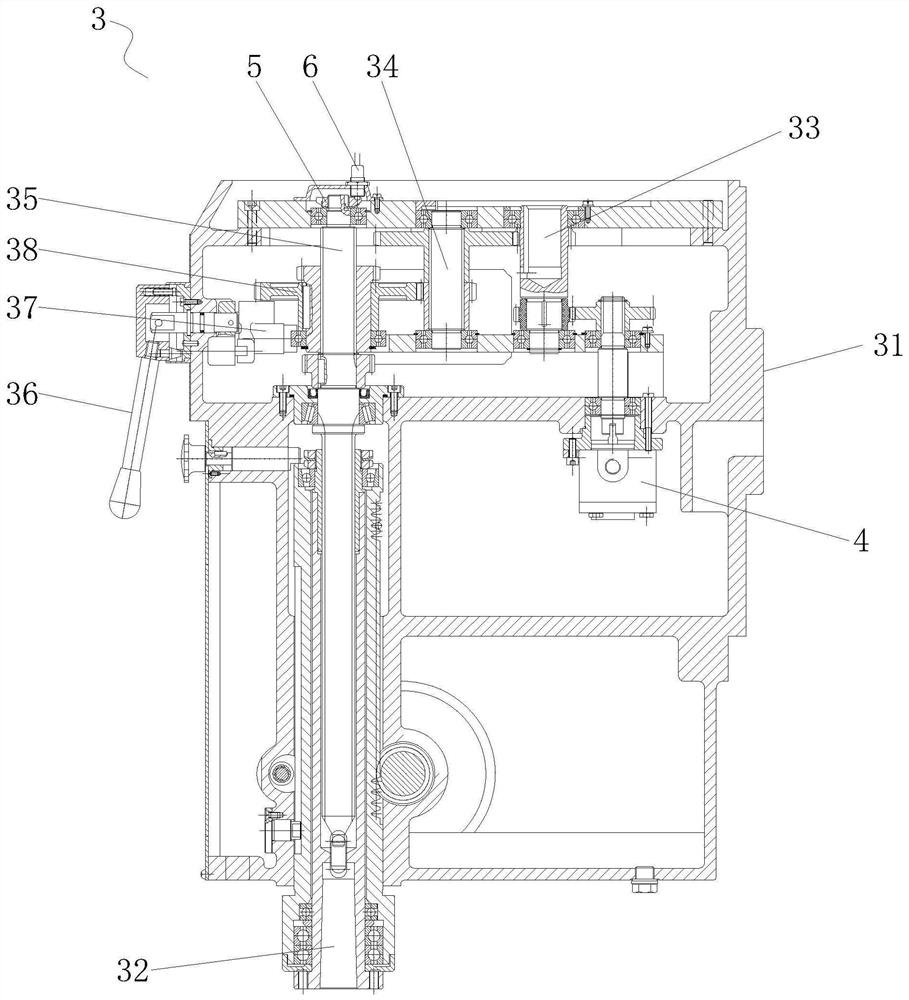

[0018] see Figure 1-2 , a high-efficiency ice-making system, including a PLC control system, an engine 1 and a compressor 2, the engine 1 and the compressor 2 are all connected to a speed-adjusting and shifting mechanism 3; the speed-adjusting and shifting mechanism 3 includes a headstock 31, a main shaft A main shaft 32, a primary shaft 33, a secondary shaft 34, a tertiary shaft 35, a shift handle 36, a fork 37, and a double gear 38 are arranged in the box 31, the output sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com