Gravure roller storage storing and taking cart for finish material printing press

A technology of veneer materials and access vehicles, which is applied in conveyors, storage devices, mechanical conveyors, etc., can solve the problem that the degree of intelligence and automation of the roller vertical warehouse cannot meet the enterprise, affect the efficiency of goods in and out of the warehouse, and restrict the conveyor. or forklift movement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

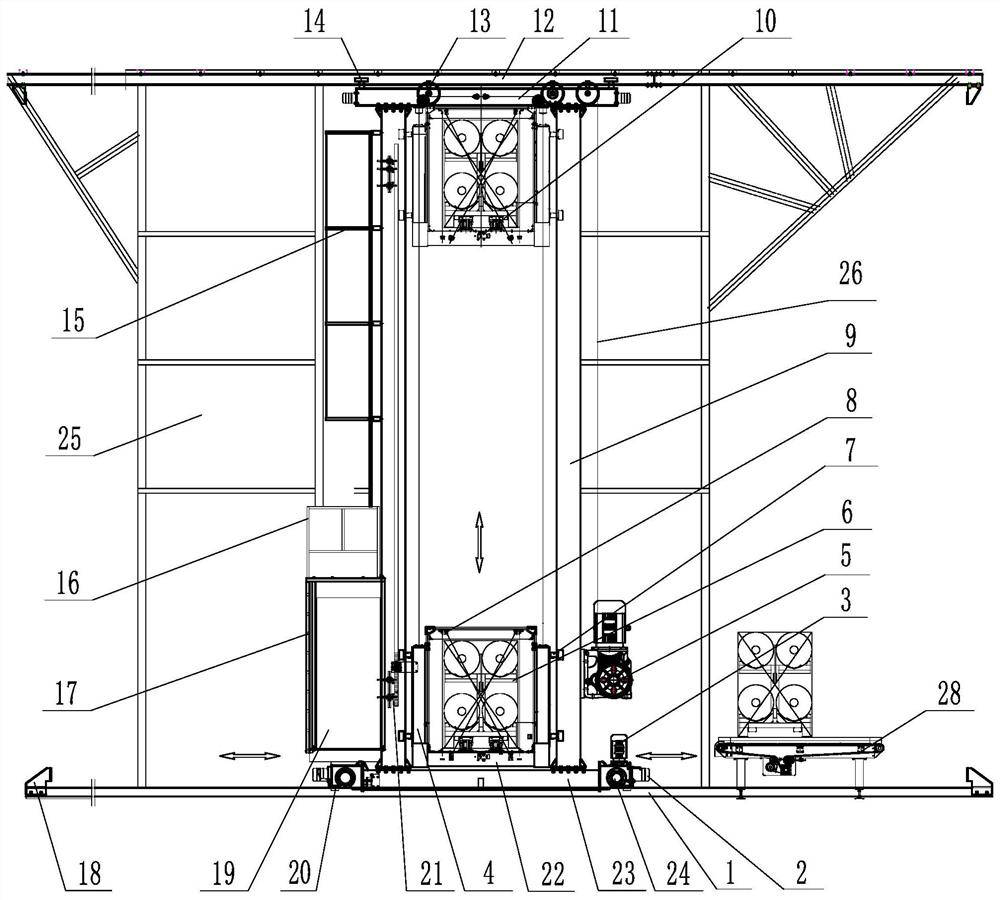

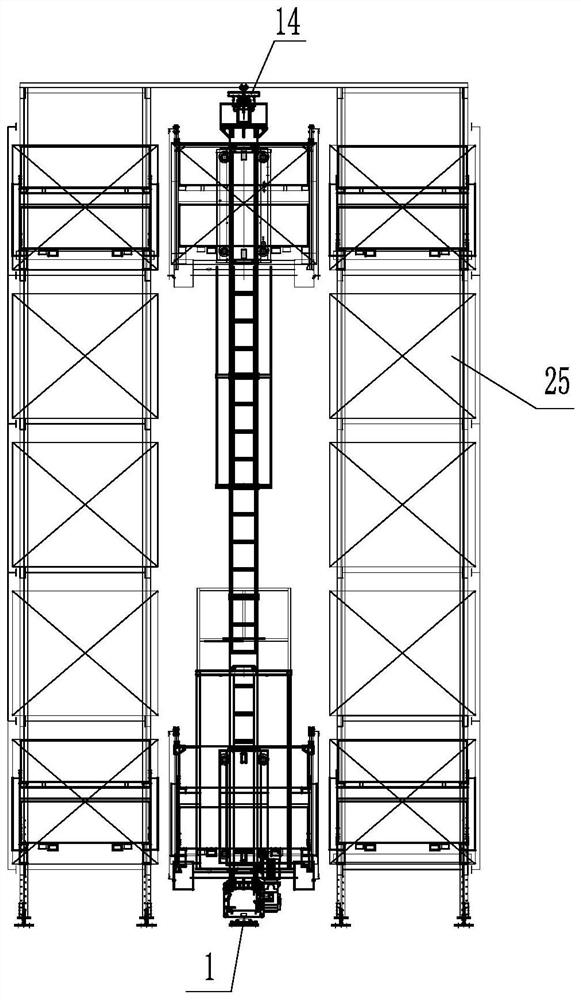

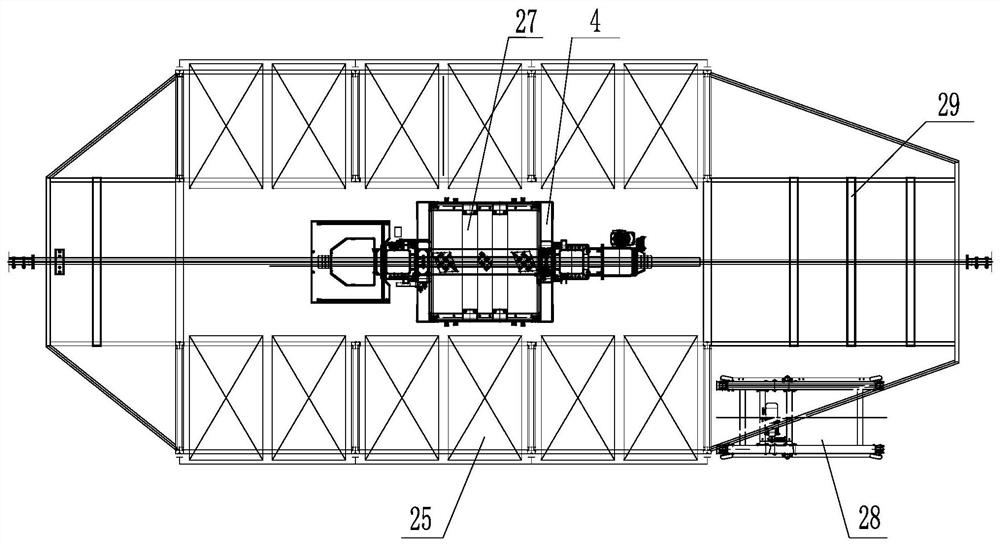

[0024] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

[0025] Such as Figure 1 to Figure 3 The gravure roller warehouse of the facing material printing machine is stored and picked up, which can work in the high and narrow aisle between the shelves; and in order to facilitate the fixing and management of the version rollers, the present invention requires four types of version rollers to be accessed according to the design and color patterns. It is a group, and the plate roller assembly bracket 6 is used for full storage and turnover (the plate roll assembly bracket is an existing technology, and its structure has been published in the patent No. Bracket" is disclosed and will not be described in detail).

[0026] The gravure roller warehouse of the facing material printing machine of the present invention is used in conjunction with the version roller assembly bracket to store the version roller assembly brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com