Preparation method of variable-twist Sorona filament and Richcel staple fiber coated fancy yarn

A technology of spun yarn and fancy yarn, which is applied in the field of spinning and can solve the problems of less research on filament composite yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

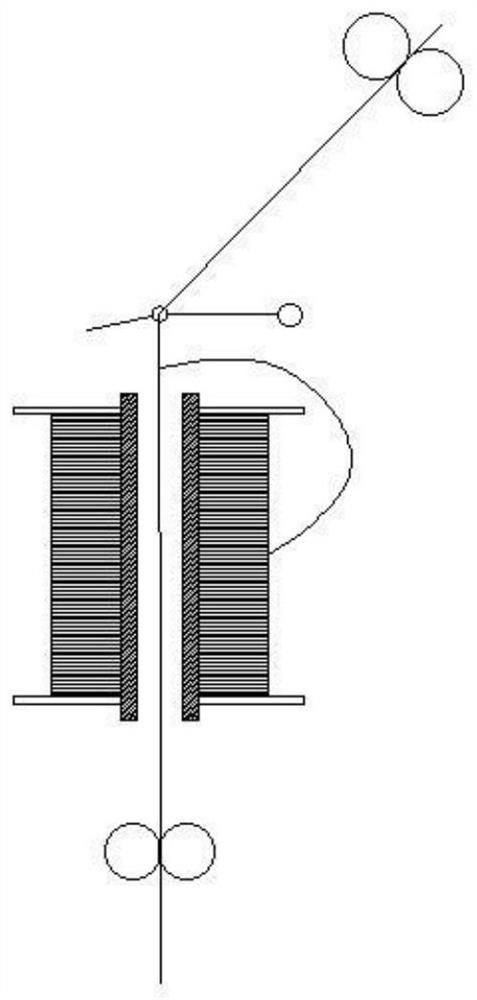

Method used

Image

Examples

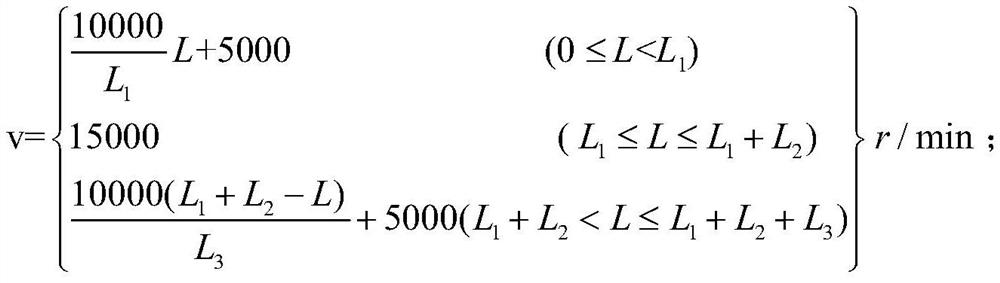

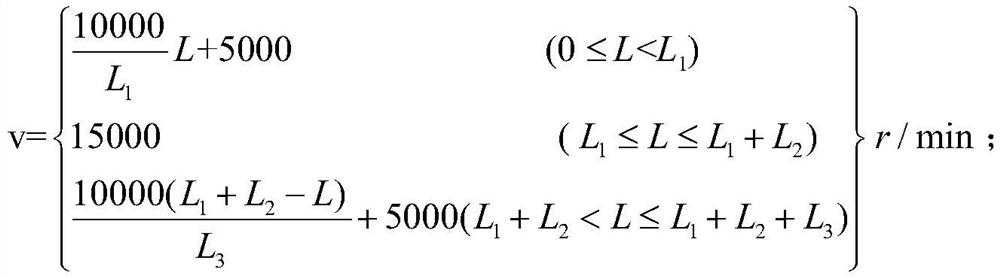

Embodiment 1

[0031] The fineness of Sorona filament is 20D; Lisa spun yarn is spun by ring spinning low-twist yarn technology, and the yarn count of Lisa spun yarn is 30 S , the twist is 400 twists / m; the line speed of the drawing roller is 21.4m / min, and the feeding speed of Sorona filament is 21.4m / min; L 1 The length is 10cm, L 2 The length is 20cm, L 3 The length is 10cm.

[0032] The prepared fancy yarn L 1 The segment has a minimum elastic elongation at break of 20%, and an elastic recovery of 65% under a load of 50g, L 2 The segment has an elastic elongation at break of 30%, and an elastic recovery of 80% under a load of 50g, L 3 The segments had an elastic elongation at break of 20% and an elastic recovery of 60% under a load of 50 g.

Embodiment 2

[0034] The fineness of Sorona filament is 30D; Lisa spun yarn is spun by ring spinning low-twist yarn technology, and the yarn count of Lisa spun yarn is 40 S , the twist is 500 twists / m; the line speed of the drawing roller is 15m / min, and the feeding speed of Sorona filament is 15m / min; L 1 The length is 30cm, L 2 The length is 50cm, L 3 The length is 40cm.

[0035] The prepared fancy yarn L 1 The elastic elongation at break of the segment is 35%, and the elastic recovery rate is 70% under a load of 50g, L 2 The elastic elongation at break of the segment is 40%, and the elastic recovery rate under 50g load is 82%, L 3 The segments had an elastic elongation at break of 37% and an elastic recovery under a 50 g load of 73%.

Embodiment 3

[0037] The fineness of Sorona filament is 50D; Lisa spun yarn is spun by ring spinning low-twist yarn technology, and the yarn count of Lisa spun yarn is 50 S , the twist is 500 twists / m; the line speed of the drawing roller is 10.2m / min, and the feeding speed of Sorona filament is 10m / min;, L 1 The length is 50cm, L 2 The length is 70cm, L 3 The length is 50cm.

[0038] The prepared fancy yarn L 1 The segment has an elastic elongation at break of 40%, and an elastic recovery of 75% under a load of 50g, L 2 The elastic elongation at break of the segment is 48%, and the elastic recovery rate under 50g load is 83%, L 3 The segment had an elastic elongation at break of 40% and an elastic recovery under a load of 50 g of 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yarn count | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com