Graphene-based composite micro-sphere for cigarette and preparation method of composite micro-sphere

A graphene-based, composite microsphere technology, applied in applications, tobacco, e-liquid filter elements, etc., can solve the problems of complex flavors and fragrances, thermal collapse of the filter rod structure, etc., to prevent collapse, optimize the taste of smoking, and increase the ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

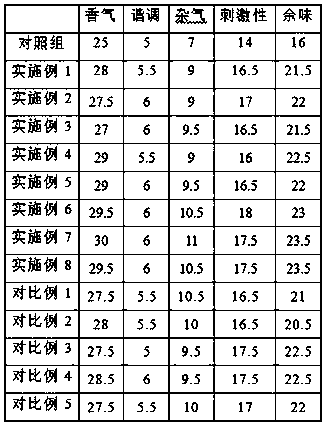

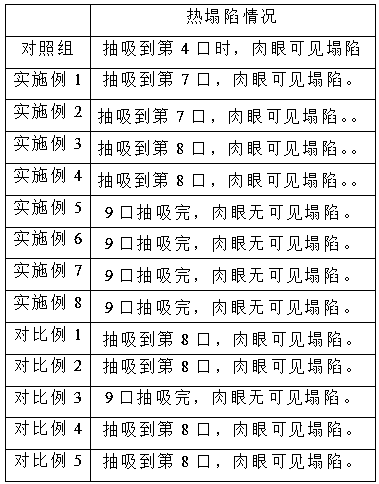

Examples

Embodiment 1

[0041] A preparation method for graphene-based composite microspheres for cigarettes, comprising the steps of:

[0042] Step (1), select a specific surface area of about 450 m 2 / g, graphene oxide with a sheet diameter of 8-12 μm and an average number of layers of 7-12 layers;

[0043] Step (2), reducing the graphene oxide selected in step (1) with a natural reducing agent to obtain reduced graphene oxide with a C / O of about 6;

[0044] In step (3), add the reduced graphene oxide obtained in step (2) into PBS buffer to a concentration of 0.5 mg / mL, and after ultrasonication until uniformly dispersed, add fruit with a mass three times the mass of reduced graphene oxide to it. Fragrant aldehydes, add dopamine hydrochloride at the same time, stir and react, centrifuge, wash the solid phase with water, and then carry out Soxhlet extraction with methanol solution containing 9% acetic acid to remove fruity aldehydes, and obtain graphene-based composite materials;

[0045] Wherein...

Embodiment 2

[0051] A preparation method for graphene-based composite microspheres for cigarettes, comprising the steps of:

[0052] Step (1), select a specific surface area of about 500 m 2 / g, graphene oxide with a sheet diameter of 7-10 μm and an average number of layers of 11-15 layers;

[0053] Step (2), reducing the graphene oxide selected in step (1) with a natural reducing agent to obtain reduced graphene oxide with a C / O of about 8;

[0054] Step (3), adding the reduced graphene oxide obtained in step (2) to PBS buffer solution with a pH of 7.5 to a concentration of 1.0 mg / mL, ultrasonically until uniformly dispersed, and adding a mass of reduced graphene oxide to it 5 times the amount of fruit-flavored aldehydes, while adding dopamine hydrochloride, stirring for 2.5 h, centrifuging, washing the solid phase with water, and then carrying out Soxhlet extraction with a methanol solution containing 12% acetic acid to remove the fruity-flavored aldehydes compounds to obtain graphen...

Embodiment 3

[0061] A preparation method for graphene-based composite microspheres for cigarettes, comprising the steps of:

[0062] Step (1), select a specific surface area of about 300 m 2 / g, graphene oxide with a sheet diameter of 12-15 μm and an average number of layers of 16-20 layers;

[0063] Step (2), reducing the graphene oxide selected in step (1) with a natural reducing agent to obtain reduced graphene oxide with a C / O of about 5;

[0064] In step (3), the reduced graphene oxide obtained in step (2) is added to PBS buffer solution with a pH of 8.0 to a concentration of 0.6 mg / mL, and after being sonicated until uniformly dispersed, the mass of reduced graphene oxide is added to it. 2.5 times the amount of fruit-flavored aldehydes, add dopamine hydrochloride at the same time, stir for 0.5 h, centrifuge, wash the solid phase with water, and then carry out Soxhlet extraction with methanol solution containing 10% acetic acid to remove fruity-flavored aldehydes Compound, obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com