Fabricated profile steel confined concrete shear wall structure

A technology for confining concrete and shear walls, applied to walls, building components, building structures, etc., can solve problems such as troubles for construction personnel, poor seismic performance, and difficult positioning of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

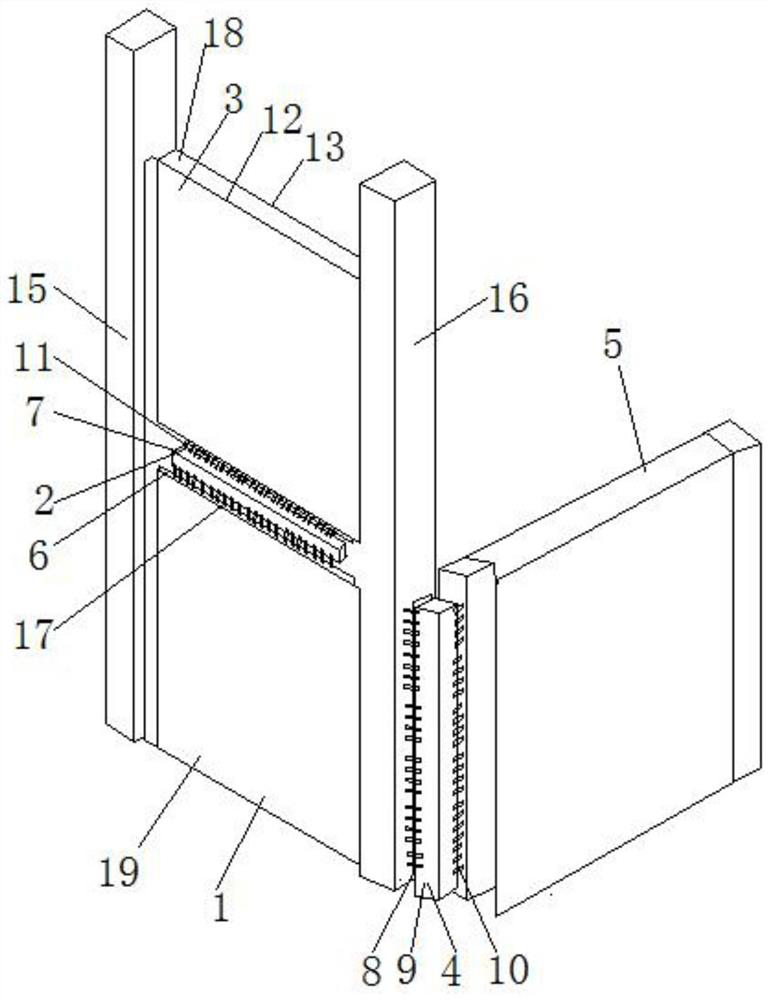

[0027] A prefabricated steel-confined concrete shear wall structure, such as figure 1 As shown, it includes: a lower shear wall unit 1, the upper side of which is connected with an upper shear wall unit 3, and the side of the lower shear wall unit 1 is connected with a side shear wall unit 5; the first connector 2 is connected to the lower shear wall Between the force wall unit 1 and the upper shear wall unit 3, the first connector 2 includes the first H-shaped steel 6 respectively connected to the lower shear wall unit 1 and the upper shear wall unit 3, and the lower shear wall unit 1 The flange on the first H-shaped steel 6 extends upward, the flange on the first H-shaped steel 6 on the upper shear wall unit 3 extends downward, and a first square steel pipe is arranged between the two first H-shaped steel 6 7. Between the flanges of the two first H-shaped steels 6 and the first square steel pipe 7, a plurality of first reinforcing ribs 11 are respectively arranged, and the p...

Embodiment 2

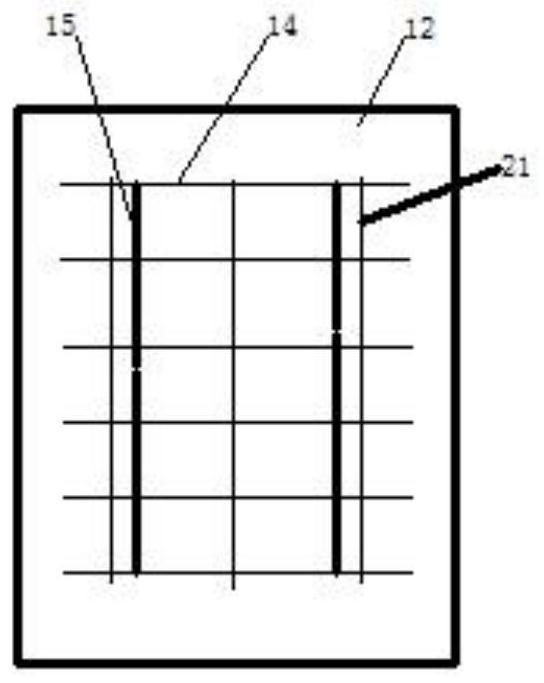

[0031] Further, on the basis of embodiment 1, such as Figure 2-3As shown, the lower shear wall unit 1, the upper shear wall unit 3 and the side shear wall unit 5 all include vertical and face-to-face first steel plates 12 and second steel plates 13 respectively, and the first steel plates 12 and the second steel plates Between 13, there are multiple layers of corrugated reinforced bars 14, each layer including two corrugated reinforced bars 14, the waveform positions of the two corrugated reinforced bars 14 intersect each other and form two nodes, and two adjacent layers of corrugated reinforced bars The nodes formed by 14 are connected by polystyrene boards 15 arranged vertically, and the periphery of the floor frame formed between the multi-layer corrugated reinforced steel bars 14 is also provided with a plurality of ring-type connecting beam stirrups 21 in parallel and equidistantly. The connecting beam stirrup 21 is vertically arranged with the corrugated reinforced stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com