Coal bunker support and construction process thereof

A construction technology and coal bunker technology, applied in shaft lining, tunnel lining, underground chamber, etc., can solve problems such as complex process, high cost, and large engineering volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

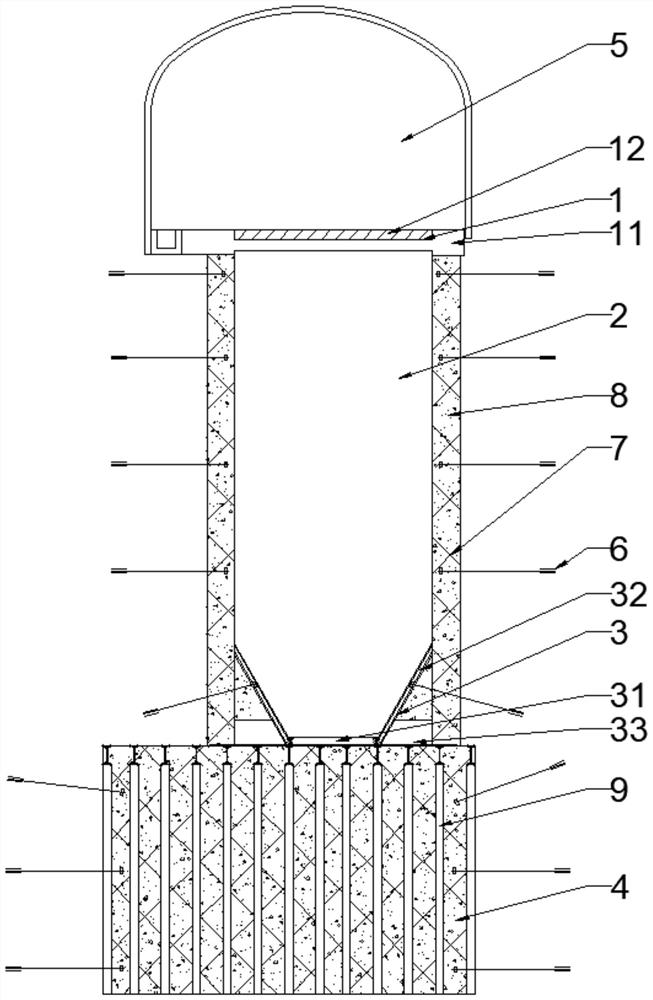

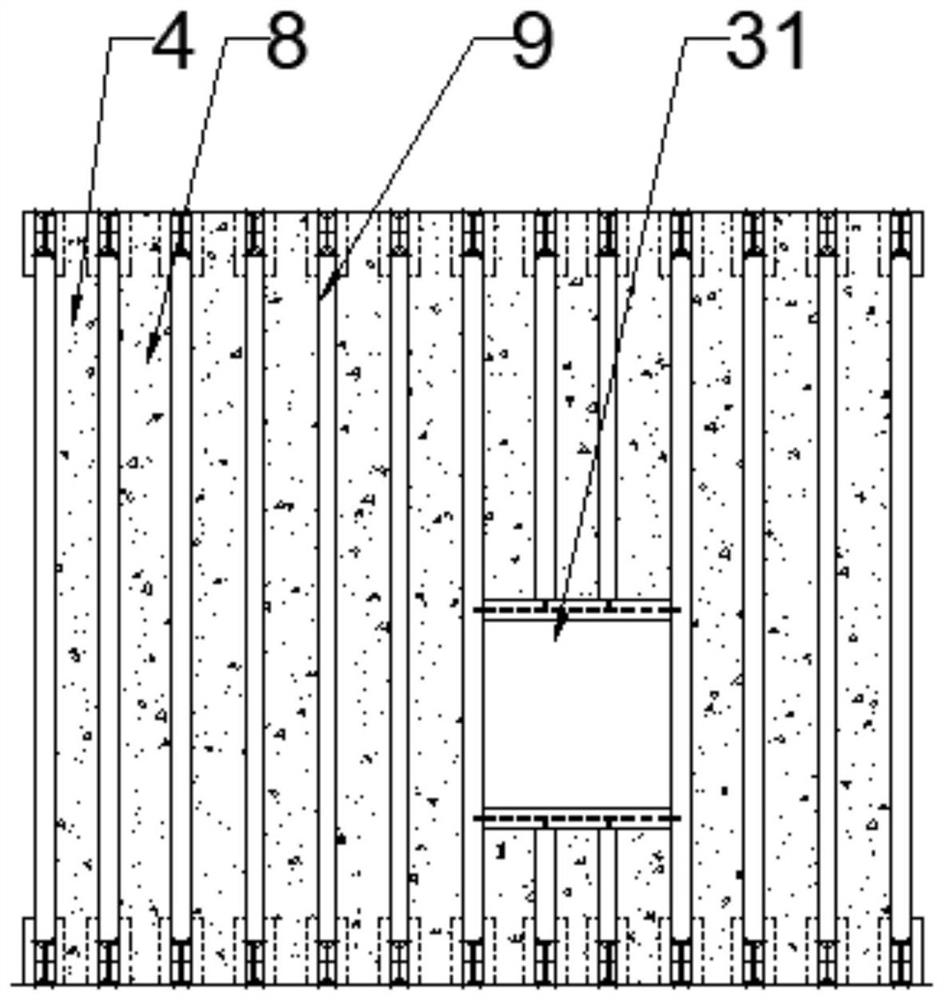

[0023] Such as Figure 1-2 As shown, the coal bunker support provided by the embodiment of the present invention includes a coal bunker and a support; the coal bunker includes a coal bunker cover plate 1, a coal bunker body 2, a coal bunker funnel 3, a loading chamber 4, and a coal bunker cover The plate 1 is set on the top of the coal bunker body 2, the coal bunker funnel 3 is set on the bottom of the coal bunker body 2, and the loading chamber 4 is set on the bottom of the coal bunker body 2; the support includes anchor net spray support, rail support, anchor net Sprayed metal shed support; coal bunker body 2 is equipped with anchor net spray support, coal bunker funnel 3 is provided with rail support, and loading chamber 4 is equipped with anchor net sprayed metal shed support.

[0024] Coal bunker cover plate 1 includes 11# mine I-beam 11 and checkered steel plate 12, with openings on checkered steel plate 12; 11# mine I-beam 11 is buried in the warehouse wall for 500 mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com