Positive-pressure high-temperature gas standard device taking sonic nozzle as standard device

A sonic nozzle, high temperature gas technology, applied in testing/calibration devices, measuring devices, instruments, etc., can solve the problems of not truly reflecting the performance of high temperature gas flowmeters, calibration of high temperature gas flowmeters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

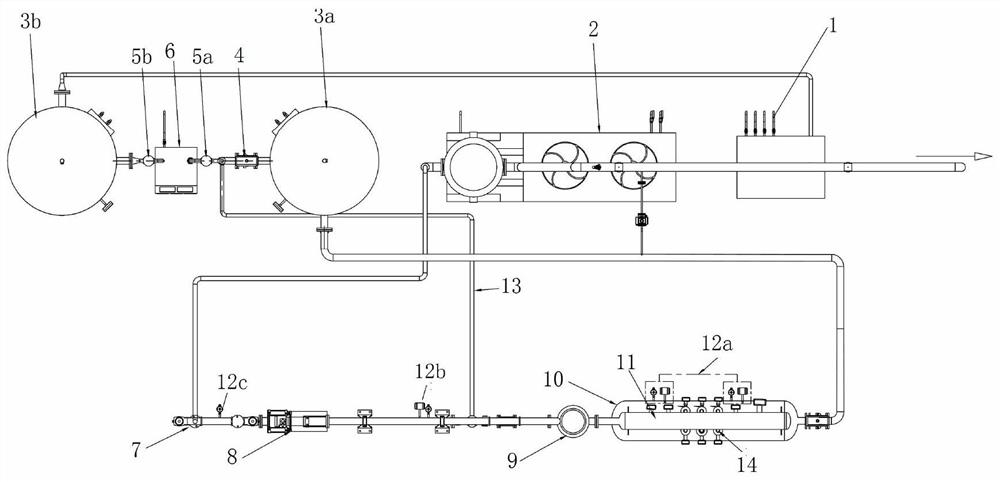

[0021] Such as figure 1 As shown, a kind of positive pressure high-temperature gas standard device using the sonic nozzle as the standard device of the present invention includes: an air compressor 1, a steady flow container, a standard device unit, a gas heating unit, a tested meter unit 8, and an air-cooled unit 2 and temperature and pressure acquisition unit. The outlet of the air compressor 1 is connected to the inlet of the flow stabilization container through a pipeline, and the outlet of the flow stabilization container is connected to the inlet of the standard unit through a pipeline. The etalon unit is composed of a stagnation container 10 and a plurality of sonic nozzles 14. The upper end of the sonic nozzles 14 is provided with an electric switch valve to select the state of the nozzle through the control of the host computer, so as to achieve the function of selecting the flow rate. A confluence pipe 11 is provided at the upper end of the stagnation container 10 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com