Multidirectional multilayer full-diameter fracture core seepage simulation device and application thereof

A seepage simulation, full-diameter technology, applied to measuring devices, teaching models, educational tools, etc., can solve the problems of being unable to simulate complex seepage conditions in the formation, and not considering multi-directional and multi-layered radial seepage conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

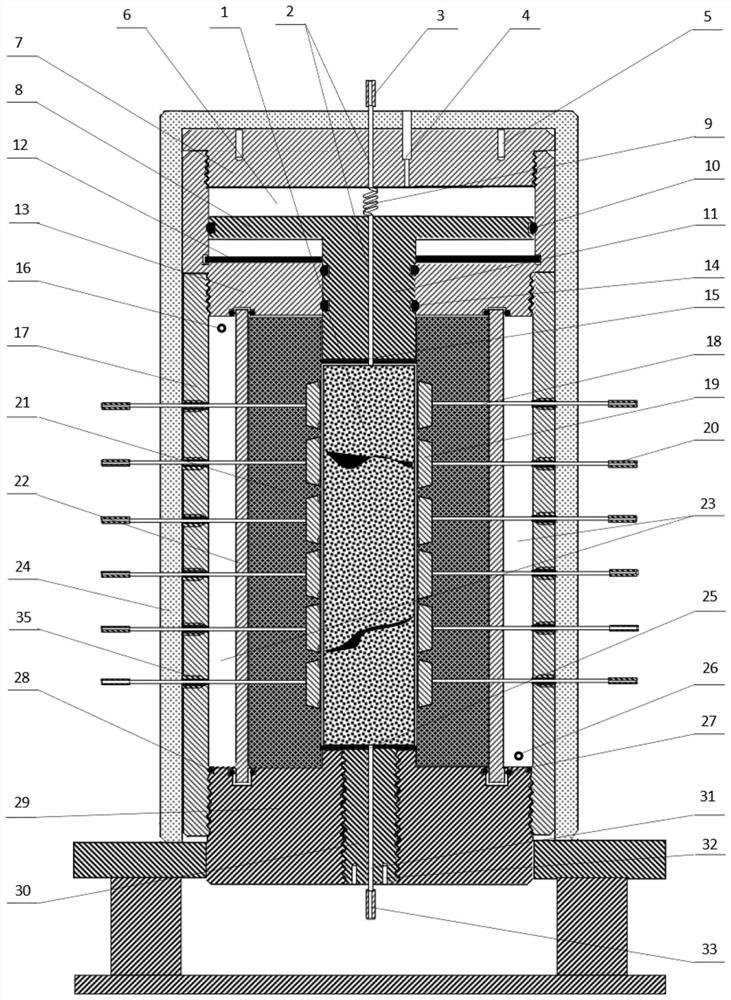

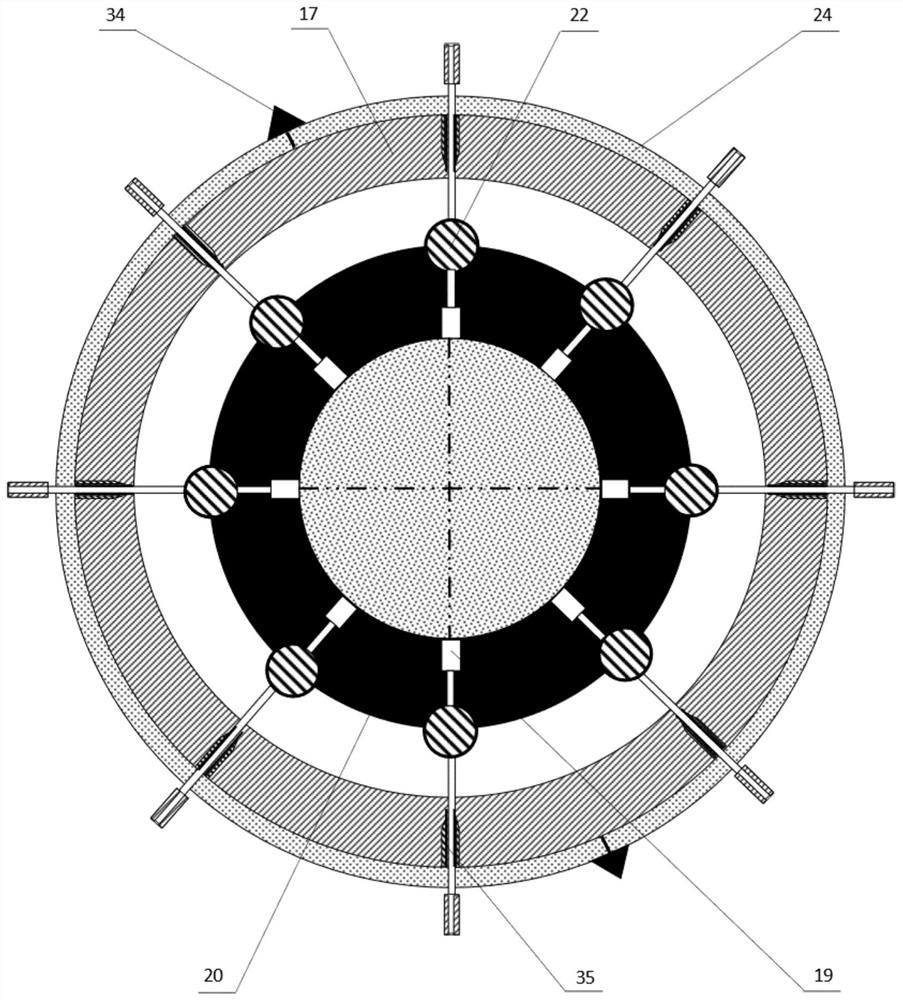

[0063] The multi-directional multi-layer full-diameter fractured core seepage simulation device provided by the present invention has a schematic diagram of its overall structure as shown in figure 1 As shown (sectional view in the front view direction), it includes a full-diameter fractured core clamping module, a radial multi-directional multi-layer seepage injection-production module, an axial seepage injection-production module, and a stress and temperature loading module.

[0064] Wherein, the full-diameter fractured core clamping module includes a high-pressure-resistant rubber sleeve 21 and a holder cylinder 17, and the inner cavity of the high-pressure-resistant rubber sleeve 21 is used as a full-diameter fractured core chamber 1 for placing a full-diameter fractured core sample, The holder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com