Central electronic hysteroscope, lens mounting end cover thereof, and uterine cavity moving operation platform

A technology of electronic palace and installation end, applied in the medical field, can solve the problems of patient injury, limit the range of activities, affect the operator's field of vision, etc., and achieve the effect of easy operation and reduced overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Reference manual attached Figure 1 to Figure 7 , the central type electronic hysteroscope provided by the present invention is described, the lens end of the central type electronic hysteroscope has a smaller size, so that the use of the central type electronic hysteroscope can be facilitated.

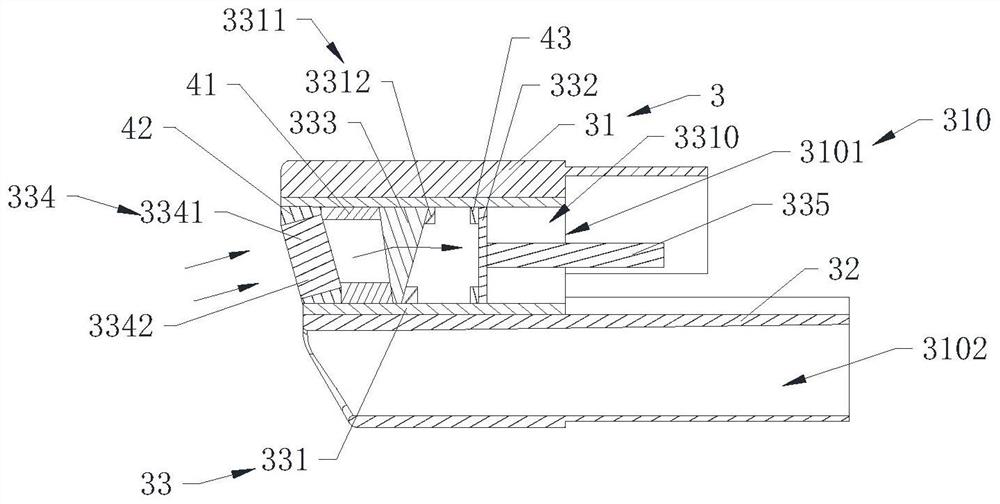

[0077] Reference manual attached figure 2 , image 3 as well as Figure 7 Specifically, the central electronic hysteroscope includes an operating handle 1, a tube body 2 and a lens mounting end cap 3, the tube body 2 is mounted on the operating handle 1, and the lens mounting end cap 3 is mounted on the The end of the tube body 2 away from the operating handle 1 .

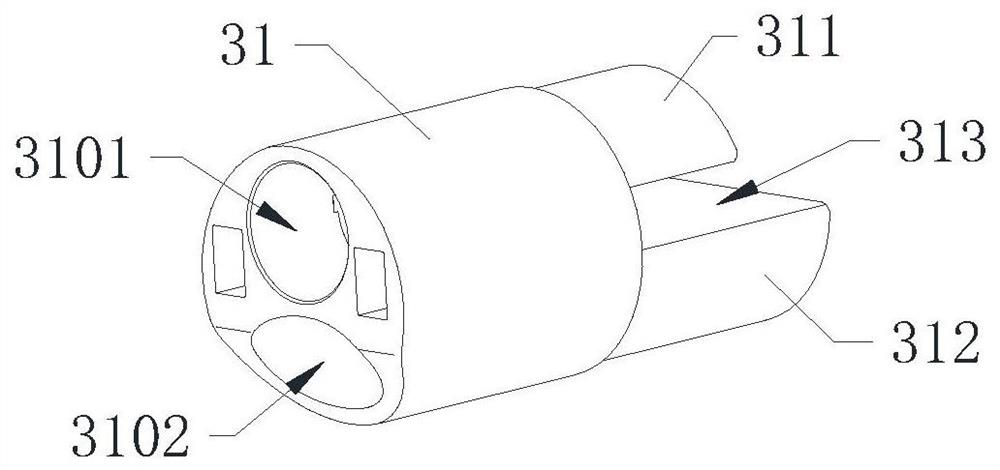

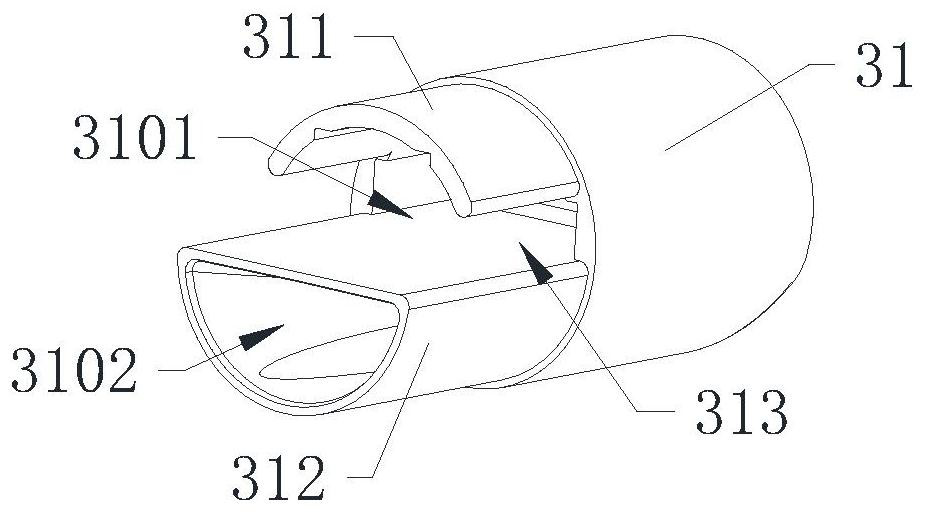

[0078] Reference manual attached figure 1 Further, the lens mounting end cap 3 includes an end cap housing 31 , an end cap partition 32 and a lens module 33 . The end cover housing 31 has an end cover cavity 310, the end cover partition 32 is installed in the end cover cavity 310, and divides the end cover cav...

Embodiment 2

[0125] Reference manual attached Figure 8 and Figure 9 The lens mounting end cap 3a of the second preferred embodiment of the lens mounting end cap provided by the present invention is described, and the structure of the lens mounting end cap 3a of the second preferred embodiment is substantially the same as that of the above preferred embodiment, The difference is that the photosensitive chip and the lens are respectively installed in the housing of the end cap to reduce the overall size of the end cap where the lens is installed.

[0126] Specifically, the lens mounting end cap 3a includes an end cap housing 31a, an end cap partition 32a, a photosensitive chip 332a and a lens assembly 334a, the end cap housing 31a has an end cap cavity 310a, and the end cap partition 32a divides the end cap cavity 310a into an upper end cap cavity 3101a and a lower end cap cavity 3102a. The photosensitive chip 332a and the lens assembly 334a are installed in the upper end cap cavity 3101...

Embodiment 3

[0155] Reference manual attached Figure 10 to Figure 15 , the third preferred embodiment of the lens mounting end cap of the central electronic hysteroscope provided by the present invention is described, the lens mounting end cap of the central electronic hysteroscope in the third preferred embodiment is the same as the above-mentioned first The difference between the first preferred embodiment and the second preferred embodiment is that the photosensitive chip and the lens assembly are independently installed on the end cover housing.

[0156] Specifically, the lens mounting end cap of the central electronic hysteroscope provided in the third preferred embodiment includes an end cap housing 31b, an end cap partition 32b, a lens assembly 33b, a photosensitive chip 34b and a prism 35b. The end cover housing 31b has an end cover cavity 310b; the end cover partition 32b is installed in the end cover cavity 310b, and divides the end cover cavity 310b into an upper end cover cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com