Vacuum purification device and purification system

A vacuuming device and vacuum technology, applied in the field of medicine and chemical industry, can solve problems such as deterioration of raw materials, and achieve the effect of reducing heating time and reducing the risk of deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

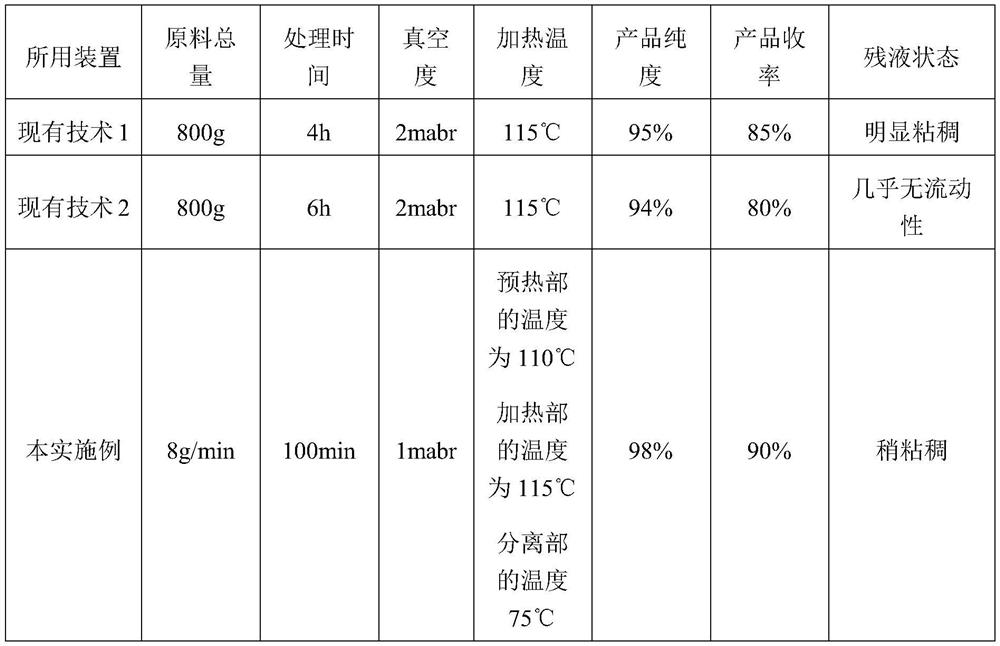

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0024] It should be noted that, in the embodiment of the present invention, the heating part 20 has a first preset temperature value A1, and the separating part 30 has a second preset temperature value A2, wherein A1>A2. That is to say, during the purification process, it is always ensured that the temperature of the heating part 20 is higher than the temperature of the separation part 30 .

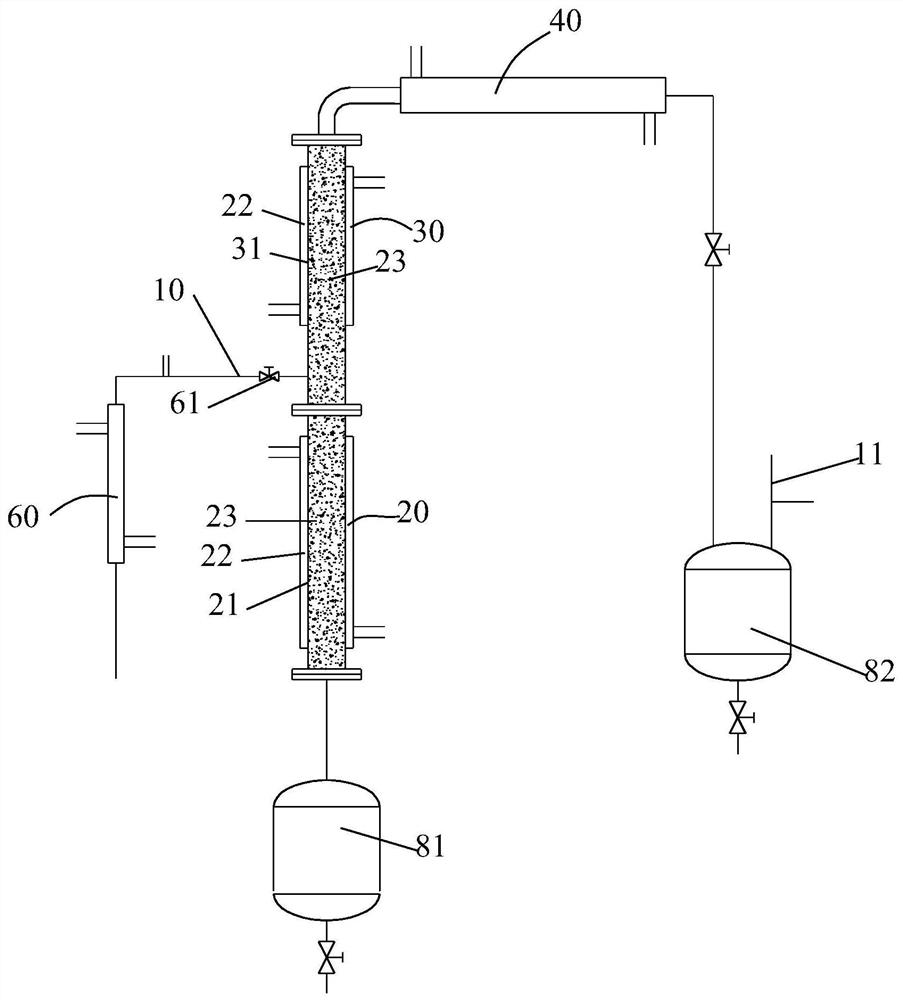

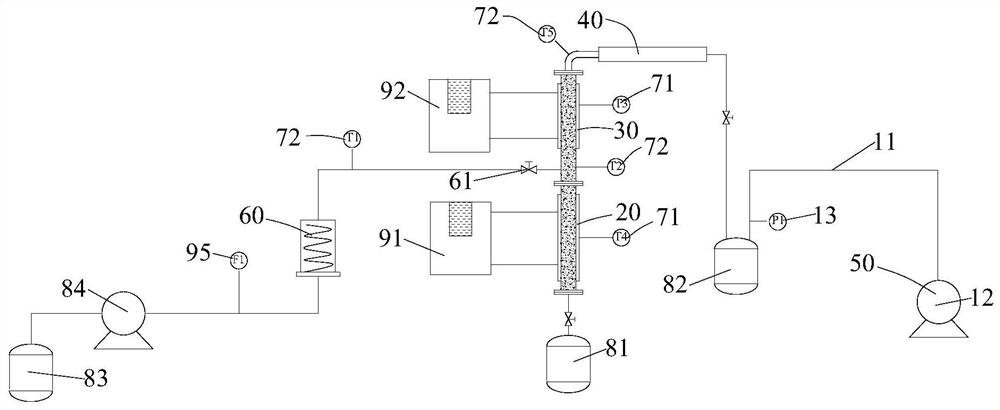

[0025] Such as figure 1 with figure 2 As shown, the embodiment of the present invention provides a vacuum purification device. The vacuum purification device includes a delivery pipeline 10 , a heating part 20 , a separation part 30 , a condensation part 40 and a vacuuming device 50 . Wherein, the con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap