Feeding mechanism for automatic feeding machining of straight-through and three-way joints

A technology of automatic feeding and feeding mechanism, which is applied in metal processing, load hanging components, transportation and packaging, etc. It can solve the problems of slow workpiece conveying efficiency, incorrect workpiece placement, and inability to be grasped and processed by grippers. , to achieve the effect of precise and efficient movements and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

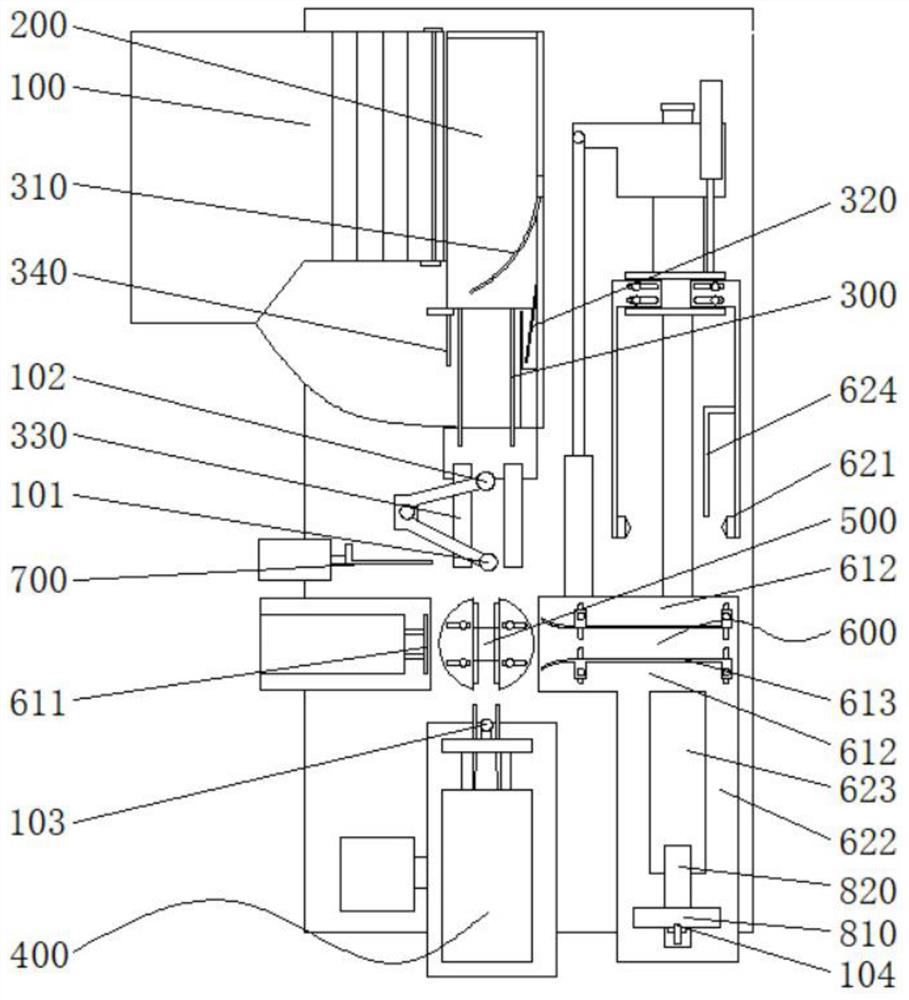

[0016] Such as figure 1 As shown, a feeding mechanism for automatic feeding and processing of straight-through and three-way joints, including a stepped feeder 100, a feeding channel 200, and a linear vibrating feeder (not shown) arranged below the feeding channel 200, feeding The end of the channel 200 is connected with a sieve slideway 300 and a sieve material rod 310 and an auxiliary guide 320 for correcting the angle of the workpiece. The material rod 340 is fastened and assembled with the fixing bolts on the end surface of the feeding channel 200 through the adjustment block. The function of the material guide rod 340 is to assist in correcting the position and angle of the workpiece so that it enters the conveying track. It also includes the workpiece grabbing mechanism 400 and the workpiece turning The mechanism 500 and the workpiece pushing mechanism 600, the workpiece grabbing mechanism 400 controls the lifting and telescopic grabbing of the workpiece through the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com