Plastic particle mixing device

A mixing device and technology of plastic particles, applied in the field of plastic processing, can solve the problems of high accumulation pressure of plastic particles, poor mixing effect, inability to mix plastic particles uniformly, etc., and achieve the effect of convenient discharging, not easy to block, and convenient and uniform mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

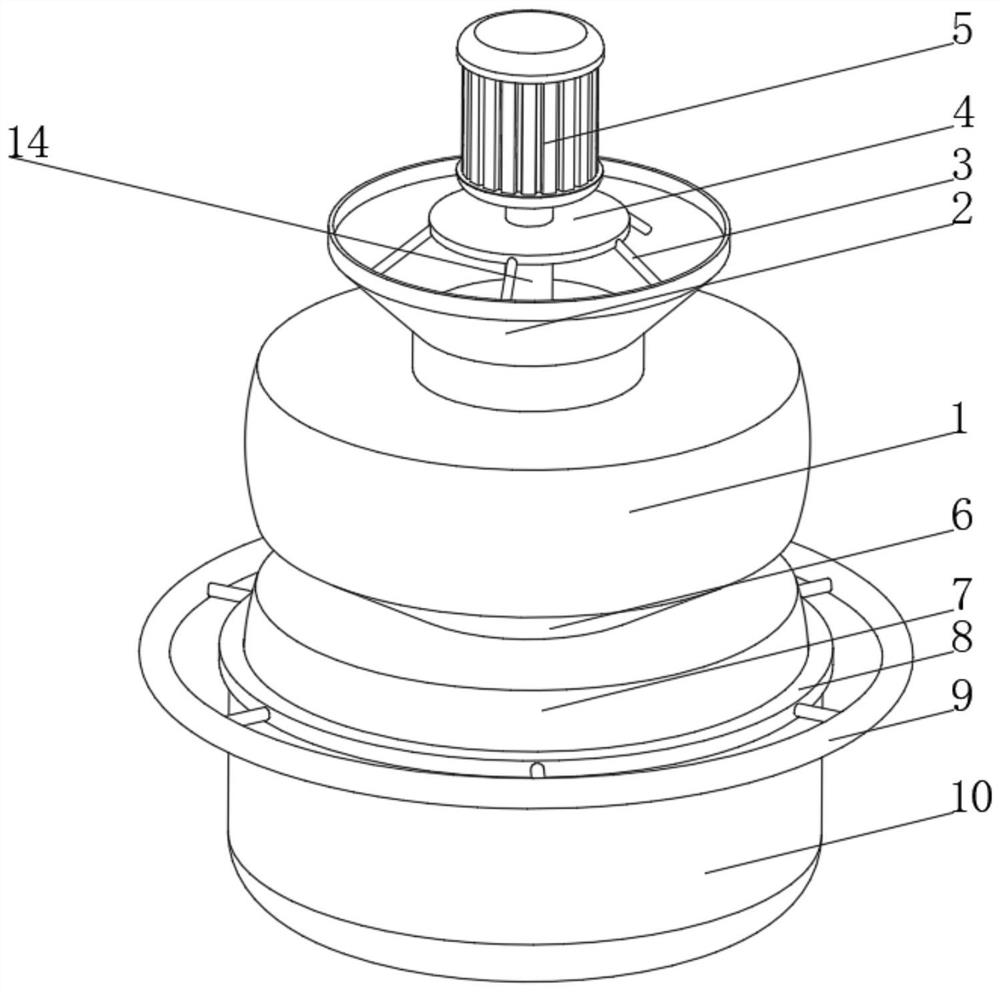

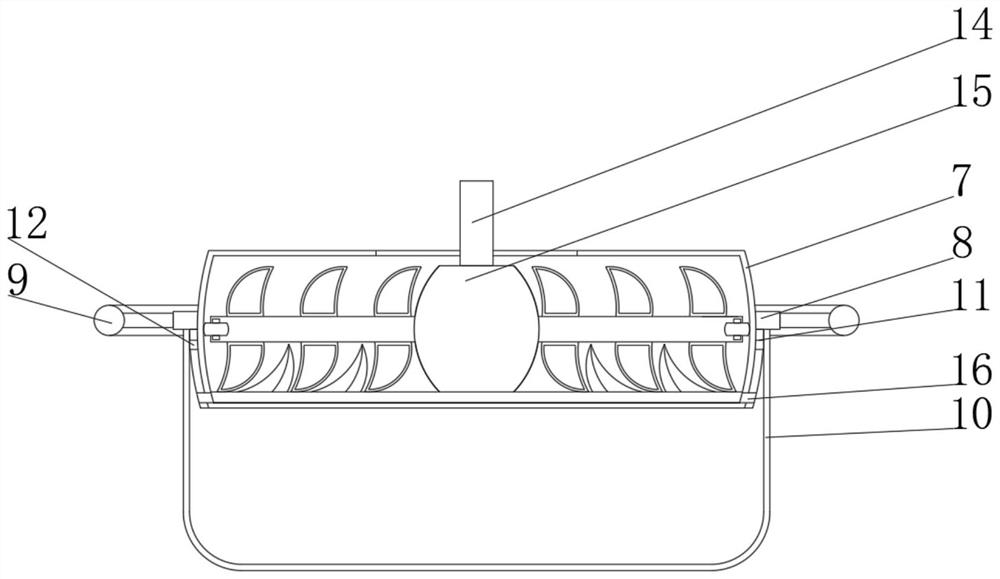

[0031] see Figure 1-3, the present invention provides a technical solution: a plastic particle mixing device, comprising a first processing box 1, the top of the first processing box 1 is provided with a feed port 2, and the top of the inner wall of the feed port 2 is fixedly connected with a bracket through a support rod 3 The plate 4 and the top of the supporting plate 4 are fixedly connected with the driving motor 5, the bottom of the first processing box 1 is connected with the second processing box 7 through the conical cylinder 6, and the outer side of the bottom of the second processing box 7 is slidingly connected with the retaining ring 8, the retaining ring 8 The outer side of the top is fixedly connected with the rotating ring 9 through the connecting rod, the outer side of the retaining ring 8 is slidably connected with the collection box 10, the side of the retaining ring 8 is provided with a long sliding hole 11, and the side of the second processing box 7 is fix...

Embodiment 2

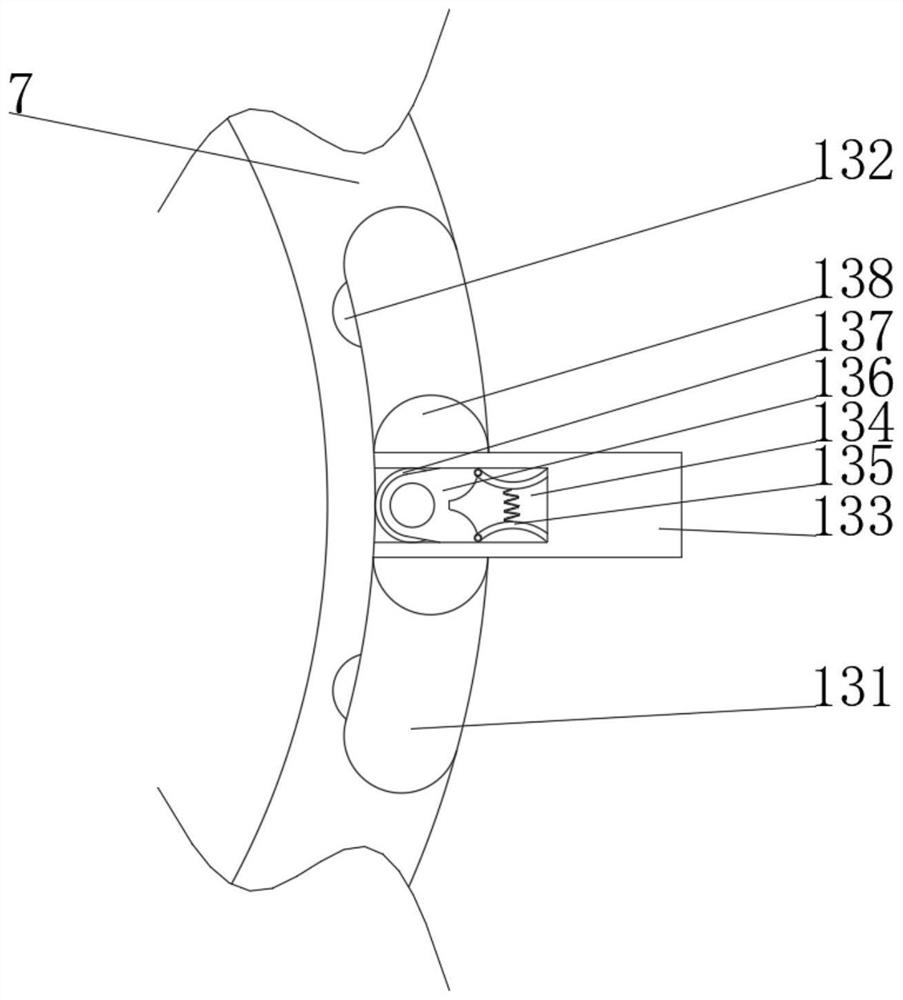

[0034] see Figure 1-5 On the basis of Embodiment 1, the present invention provides a technical solution: the stirring device 15 includes a stirring seat 151, the stirring seat 151 is provided with a movable chamber 152, and both sides of the movable chamber 152 inner wall are provided with movable holes 153, and the movable holes 153 The inner wall is slidingly connected with a stirring rod 154, and one end of the stirring rod 154 located inside the movable chamber 152 is fixedly connected with a compression magnet 155, and the end of the stirring rod 154 away from the compression magnet 155 penetrates the movable hole 153 and extends to the outside of the stirring seat 151. 154 is located at the top and bottom of one end outside the stirring seat 151 and is fixedly connected with stirring blades 156. The end of the stirring rod 154 away from the compression magnet 155 is rotatably connected with a roller 159, and both sides of the bottom of the stirring seat 151 are fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com