Device for taking out and layering cut water-retaining cotton in batches

A layering device, cotton cutting technology, applied in the direction of pile separation, object separation, transportation and packaging, etc., can solve the problems of affecting work efficiency, inconvenient to take piece by piece, and low efficiency of taking out, so as to improve work efficiency and reduce Manual processing flow, high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

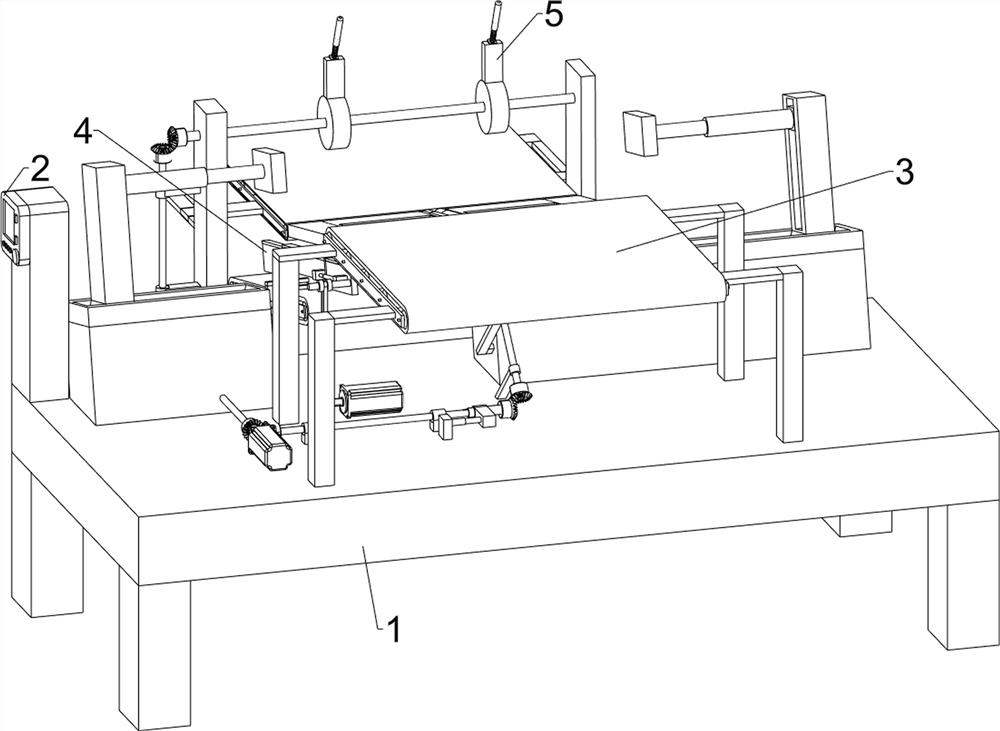

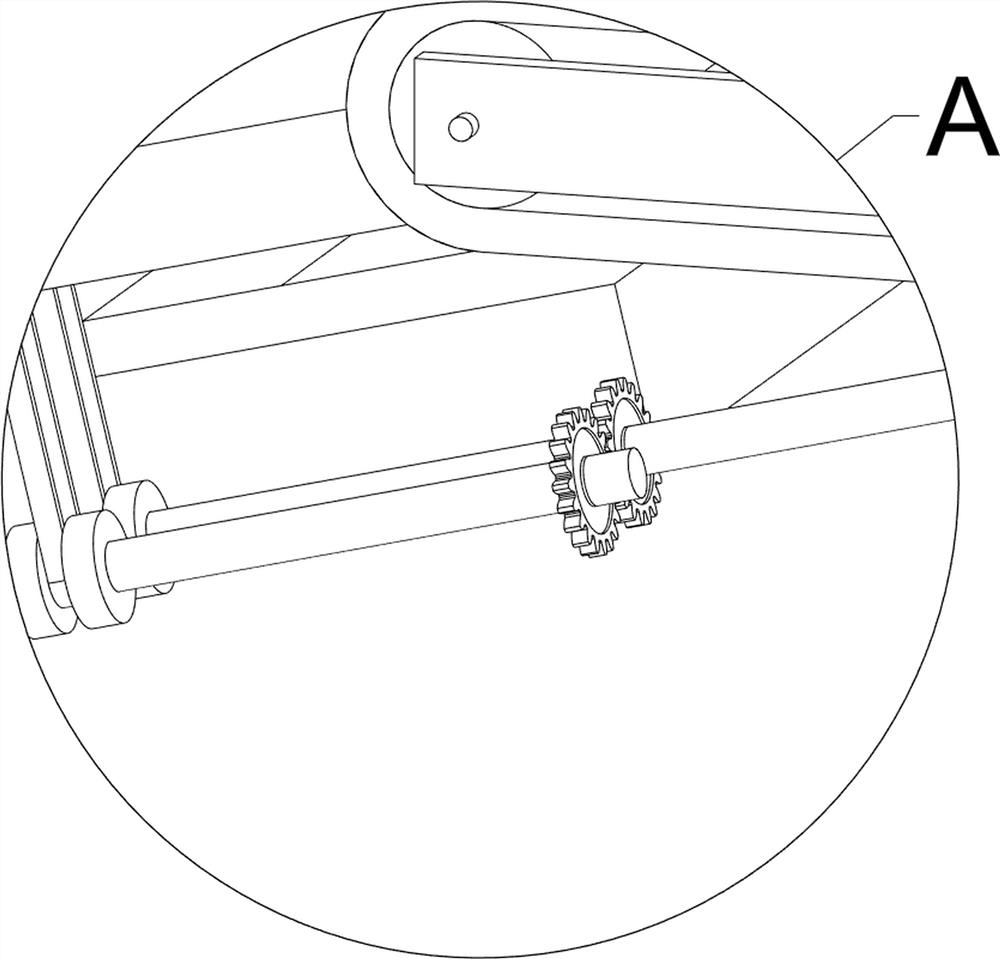

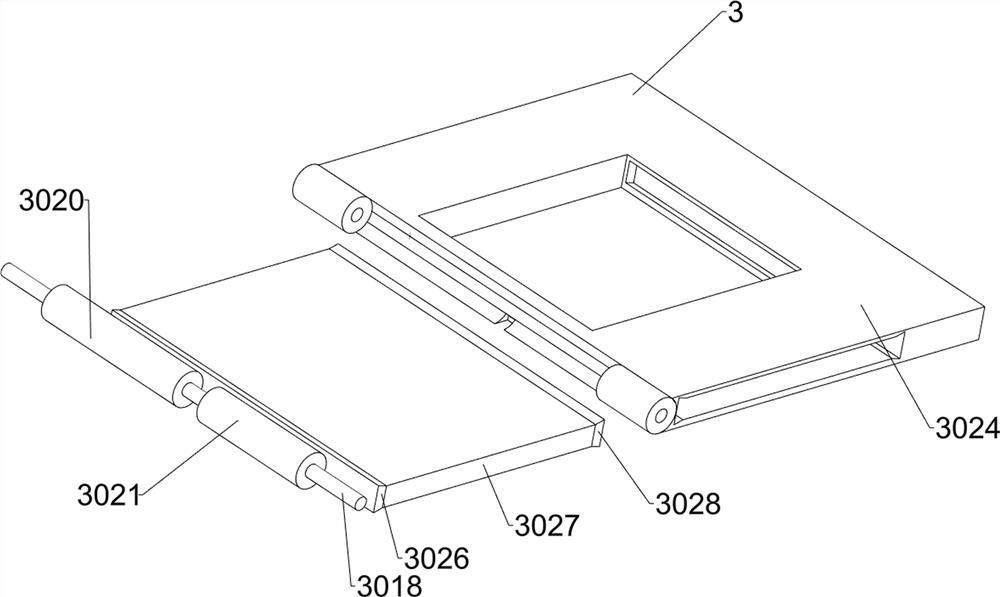

[0029] A kind of water-retaining cotton cutting piece after taking out layering device in batches, such as Figure 1-9 As shown, it includes an underframe 1, a controller 2, a cotton piece take-out mechanism 3, a slice mechanism 4 and a scrap collection mechanism 5; the underframe 1 is connected to the controller 2; the underframe 1 is connected to the cotton piece take-out mechanism 3 The underframe 1 is connected with the fragmentation mechanism 4; the underframe 1 is connected with the scrap collection mechanism 5;

[0030] Working principle: When preparing for work, place the device on a horizontal surface, turn on the power, and the cut water-retaining quilt is transported to the cotton piece take-out mechanism 3. At this time, the cut part of the water-retaining quilt is in the shape of a field and there is a surplus on the outside The water-retaining cotton frame is controlled by the controller 2 to control the cotton sheet removal mechanism 3 to take out the water-reta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com