Patents

Literature

35results about How to "Low extraction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of 2,3-dichloropyridine

ActiveCN102086174AGuaranteed qualityAvoid problems that are prone to side effectsOrganic chemistry3-AminopyridineDegradation reaction

The invention relates to a production method of 2,3-dichloropyridine, solving the problem that byproducts are easily generated through 2-position chlorination reaction so as to cause the final product quality to be instable, for example, intermediate purification is carried out but yield and environment are influenced, and the working efficiency is reduced. The production method of the 2,3-dichloropyridine comprises the following steps: 1) carrying out degradation reaction: hydrolyzing 2-chloro nicotinamide used as a starting material, and carrying out solid-liquid separation to obtain 2-chlorine-3-aminopyridine; and (2) successively carrying out diazotization reaction and 3-position chlorination reaction: successively carrying out diazotization reaction and 3-position chlorination reaction on 2-chlorine-3-aminopyridine to obtain 2,3-dichloropyridine. The production method has the beneficial effects that (1) the difficulty that the byproducts are easily generated because 2-position chlorination is successfully avoided, thereby ensuring the quality of the intermediate product 2-chlorine-3-aminopyridine; and (2) because the intermediate product 2-chlorine-3-aminopyridine is not dissolved in strong basic aqueous solution, the product can be directly taken out by vacuum filtration, and is easy to purify.

Owner:南京广通医药化工有限责任公司

Process for extraction refining amygdalin

The invention provides a process for extraction refining amygdalin which consists of, disintegrating the plant raw material containing rich bitter apricot seed into powder, removing the grease from the raw material powder by using CO2 as extracting agent, carrying out decompression segregation to the carbon dioxide containing vegetable fat, charging alcohol into ground-slag containing bitter apricot seed glycosides by the solid-to-liquid ratio of 1 : 3-10, agitating, filtering by suction to obtain the filter liquor, distilling and drying the filter liquor to obtain crude product of bitter apricot seed glycoside, dissolving the bitter apricot seed glycoside into ethanol, low temperature crystallizing, filtering and drying to obtain the high purity bitter apricot seed glycosides.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Process method for recovering indium and germanium from germanium concentrate

The invention discloses a process method for recovering indium and germanium from germanium concentrate, which relates to the technical field of wet-process metallurgy, in particular to a process method for recovering indium from hydrochloric distillate of the germanium concentrate by using bi-alkali neutralization and then using a P204 extraction method. The process method provided by the invention comprises the steps of chlorination leaching and distillation of the germanium concentrate, bi-alkali neutralization of the distillate and recovery of the indium and germanium in the neutralized residues. By using the method, the recovery rate of the indium can be up to 90.5-95.5% and the recovery rate of the germanium in the distillate can be up to 85.0-90.0%.

Owner:YUNNAN DONGCHANG METAL PROCESSING

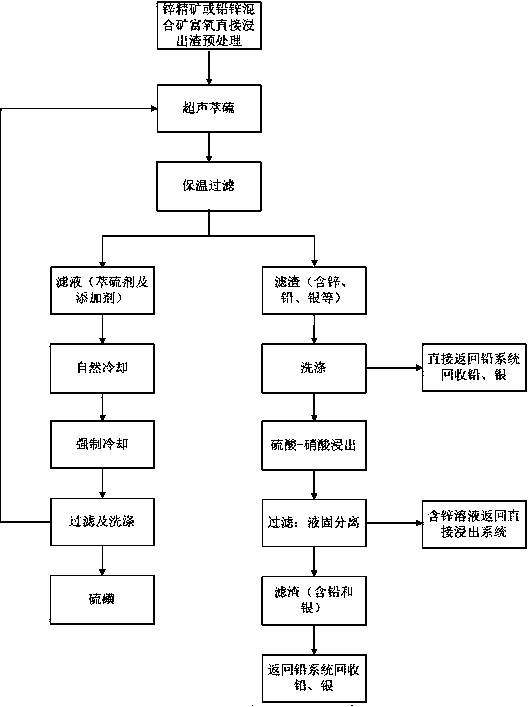

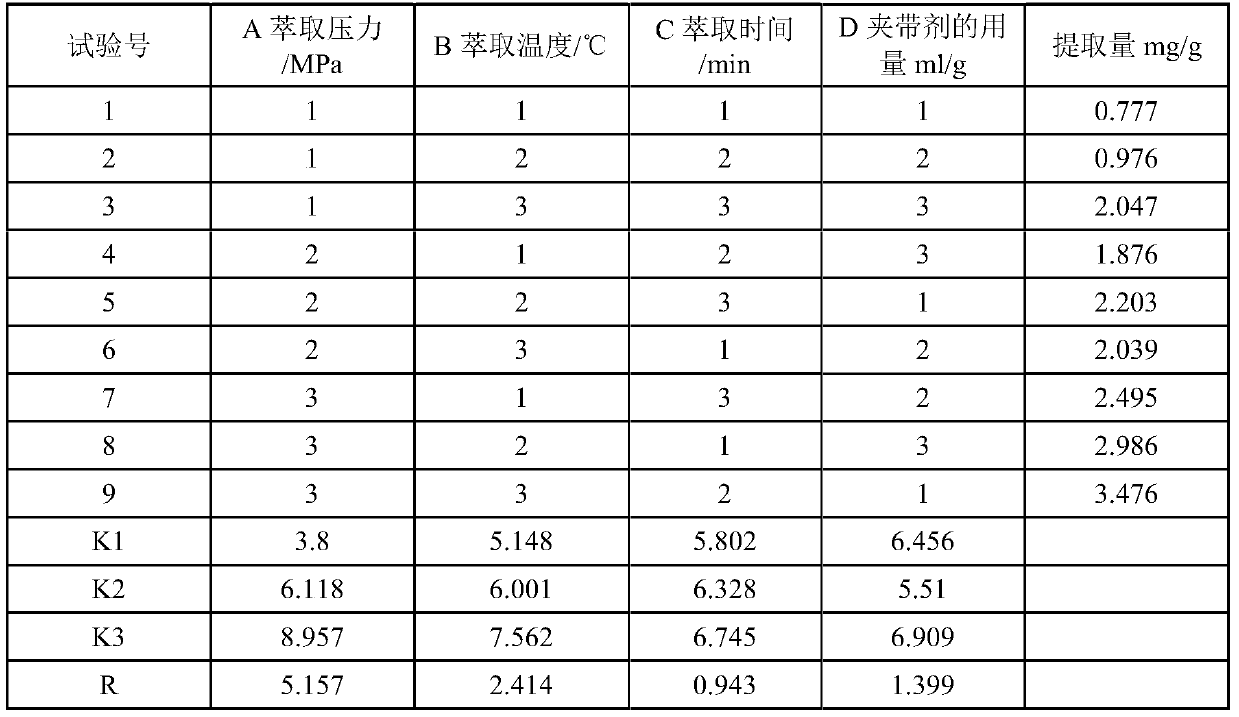

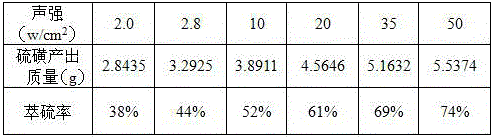

Method for recovering sulfur, lead, zinc and silver from oxygen-rich direct leaching residues of zinc concentrate or lead and zinc mixed ores by virtue of ultrasonic wave intensification

ActiveCN104195344AIncrease throughputReduce processingSulfur compoundsProcess efficiency improvementTetrachloroethyleneSulfur

The invention discloses a method for recovering sulfur, lead, zinc and silver from oxygen-rich direct leaching residues of zinc concentrate or lead and zinc mixed ores by virtue of ultrasonic wave intensification, belonging to the field of comprehensive recycling of non-ferrous metal metallurgy. The method disclosed by the invention comprises the following steps: by using tetrachloroethylene or trichloro ethylene as a solvent, extracting elemental sulfur from the oxygen-rich direct leaching residues of zinc concentrate or lead and zinc mixed ores, which are dried, ground, and sieved by virtue of ultrasonic wave intensification, preserving heat and filtering, after naturally cooling and forcibly cooling the filtrate and filtering to obtain a sulfur product, and returning a regenerated sulfur extraction agent to a sulfur extraction step; and enriching zinc, lead and silver in the residues, wherein the residues can be directly fed to a lead system to recover zinc, lead and silver, or the residues are firstly leached to recover zinc, filter residues are fed to the lead system to recover silver, and zinc-containing filtrate is returned to a direct leaching system. The method disclosed by the invention is simple, energy-saving and high in sulfur recovery rate and product quality. The sulfur extraction process is sealed, so that the method is free from environmental pollution and is particularly suitable for comprehensively utilizing normal pressure / high pressure oxygen-rich direct leaching residues of zinc concentrate or lead and zinc mixed ores.

Owner:株洲起源科技有限责任公司

Tributyl phosphate extraction resin for zirconium-hafnium separation and preparation method thereof

ActiveCN101643847AEfficient separationEliminate emulsificationProcess efficiency improvementAlcoholSeparation coefficient

The invention relates to tributyl phosphate extraction resin for zirconium-hafnium separation and a preparation method thereof. The preparation method is characterized by comprising the following steps: adding a solvent into a reaction kettle, wherein the solvent is a mixture of water and alcohols and the mixed weight ratio of the water and the alcohols is 100:2-100; after the solvent is stirred evenly, adding resin into the solvent, wherein the weight ratio of the solvent to the resin is 100:5-100; after the mixture is stirred evenly, adding tributyl phosphate into the mixture, wherein the weight ratio of the tributyl phosphate to the resin is 15-400:100; and stirring the mixture for 0.5 to 20 hours at the temperature of between 10 and 100 DEG C, and filtering the mixture to obtain the TBP extraction resin. The TBP-resin prepared by the method serving as the extraction resin for filling an extraction chromatographic column can effectively separate zirconium and hafnium, fully exerts the advantages of a liquid-liquid extraction process such as large TBP extracted zirconium capacity and large zirconium-hafnium separation coefficient, and eliminates the problem of emulsification produced by liquid-liquid extraction so as to successfully implement a zirconium-hafnium TBP extraction separation process.

Owner:有研资源环境技术研究院(北京)有限公司

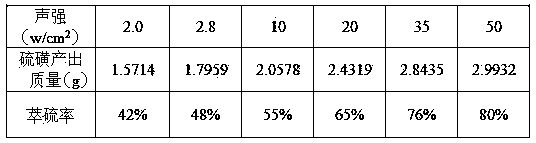

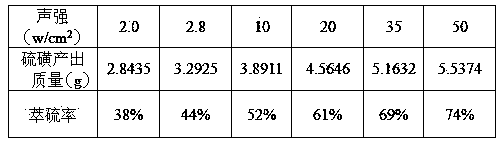

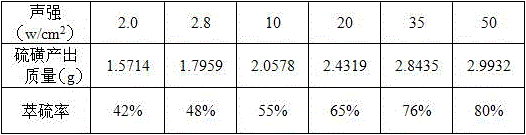

Ultrasonic extraction method and process for processing slag containing elemental sulfur

InactiveCN104229745AIncrease throughputReduce processingSulfur compoundsProcess efficiency improvementTetrachloroethyleneSlag

The invention discloses an ultrasonic extraction method and process for processing slag containing elemental sulfur. One or a mixture of more of tetrachloroethylene, trichloro ethylene, methylbenzene and xylene is adopted as a solvent; ultrasonic extraction is carried out on the slag containing elemental sulfur; the ultrasonic frequency is 20-200KHz; and the sound intensity is 2.0-50w / cm<2>. According to the ultrasonic extraction method, low-temperature extraction can be achieved without high temperature, energy consumption can be greatly reduced, and the process is low in cost, simple and feasible in operation, high in extraction efficiency, large in raw material processing amount, low in extracting agent loss and significant in composite economic results.

Owner:株洲起源科技有限责任公司

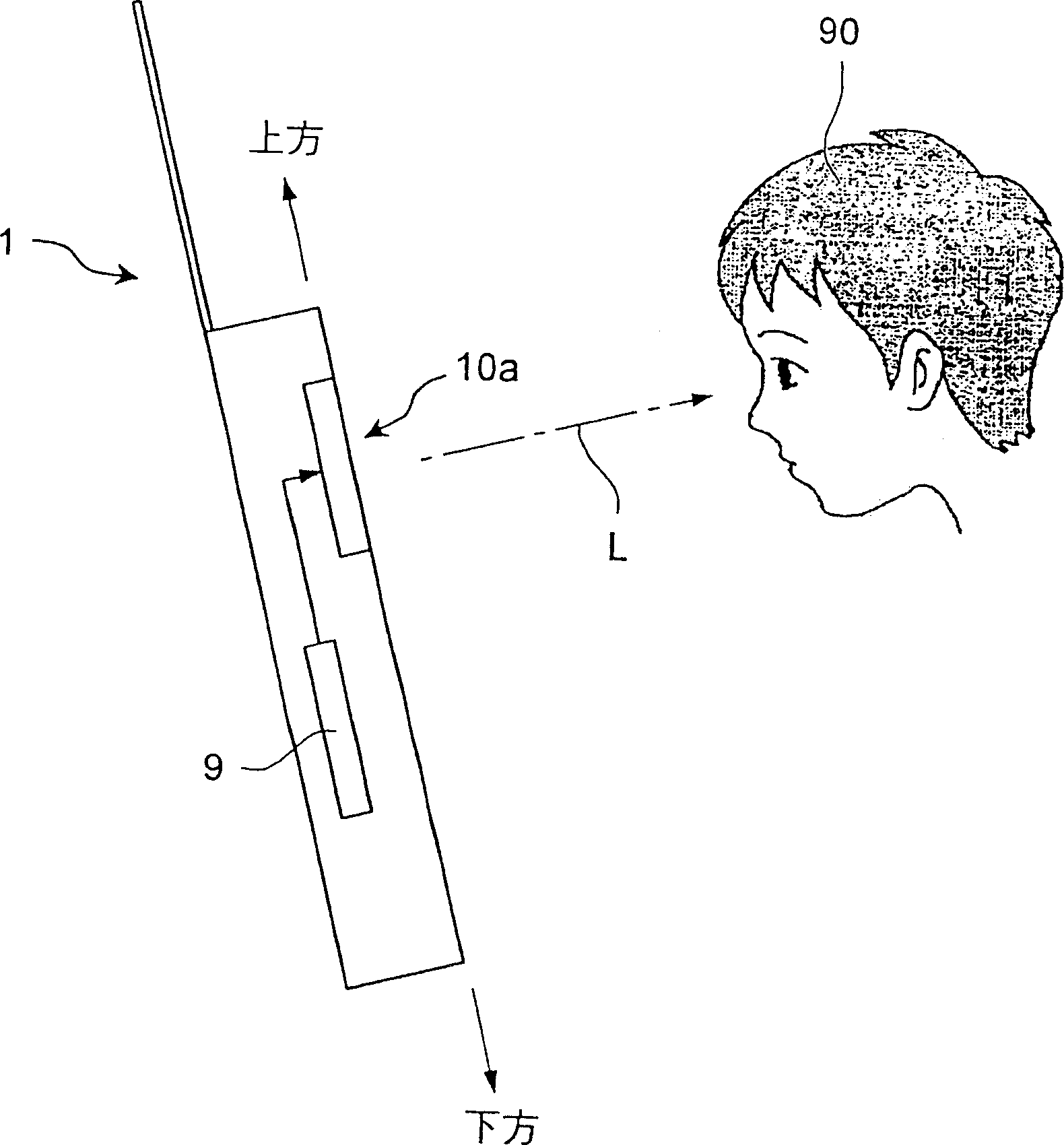

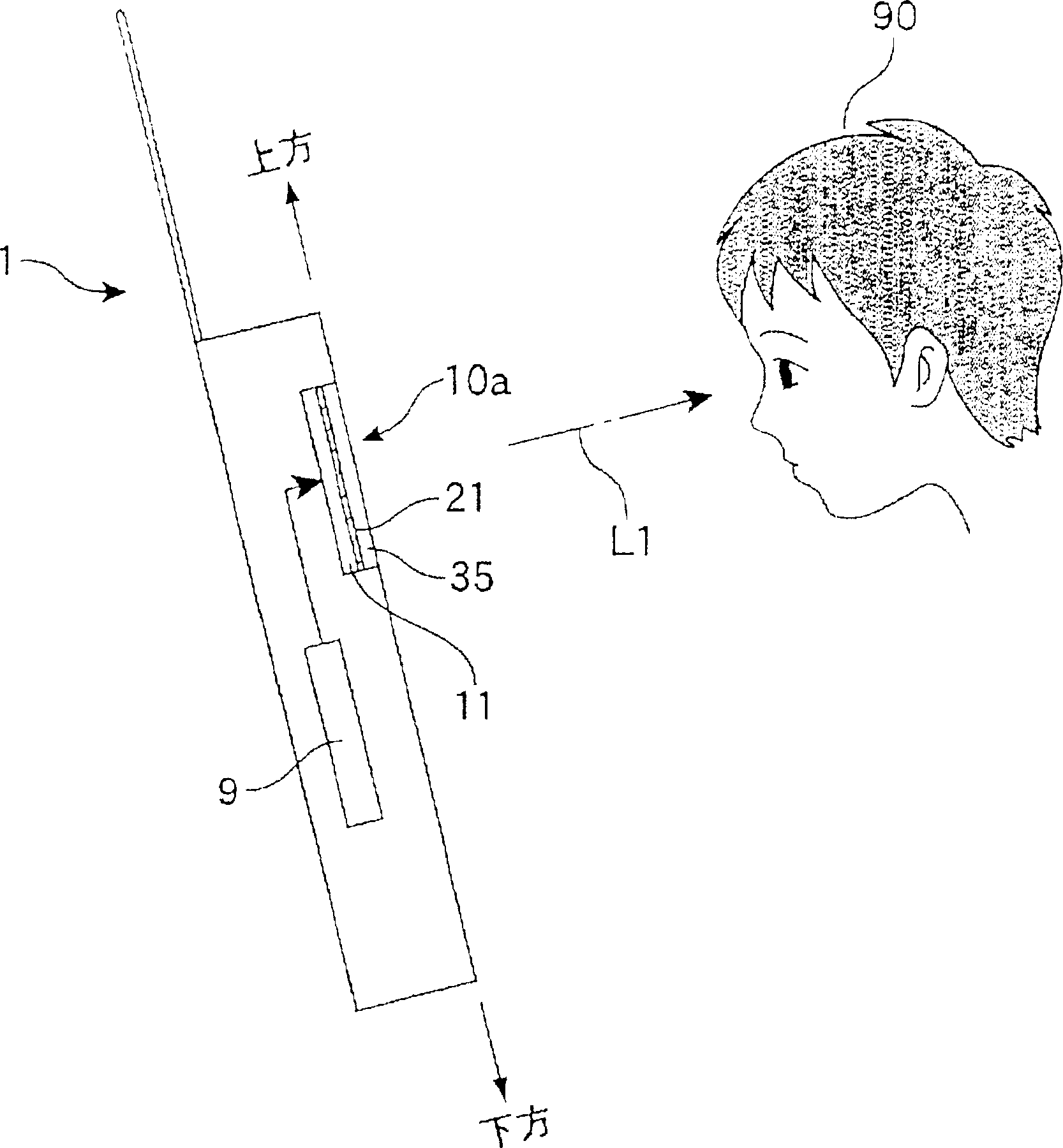

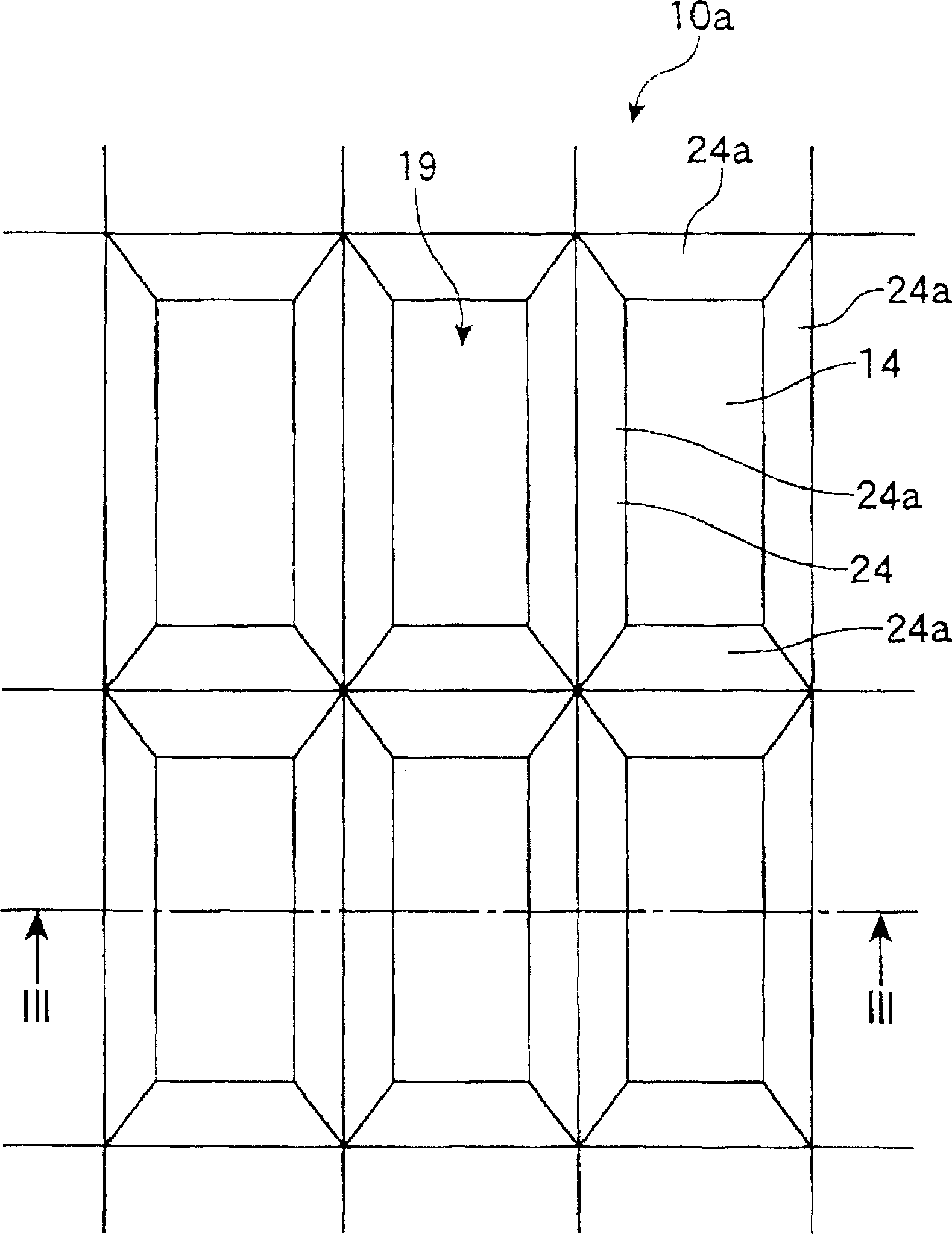

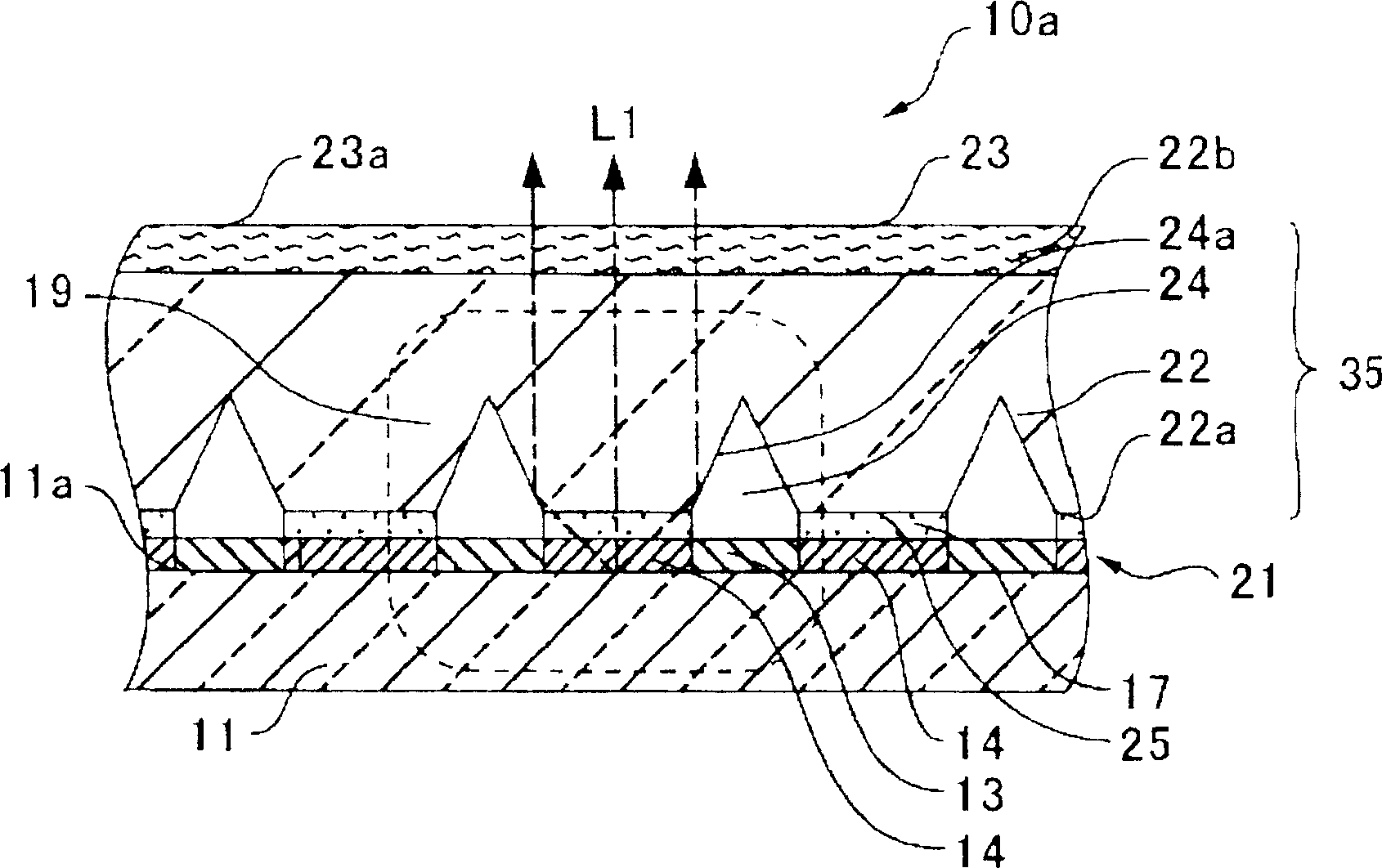

Self-illuminating element, display faceboard, method for producing display device and self-illuminating element

InactiveCN1784090AMeet thinnessImprove removal efficiencyElectroluminescent light sourcesSolid-state devicesRefractive indexDisplay device

The object of the present invention is to provide a display panel with high light extraction efficiency. The provided display panel has a plurality of self-luminous elements arranged in a two-dimensional matrix, and the self-luminous elements include: a display body layer, which Comprising a light-emitting element; and a transparent output layer, the layer is located in the emission direction of the above-mentioned display body layer, and has an angle conversion part that converts the propagation direction of the output light output from the above-mentioned light-emitting element to the above-mentioned emission direction; the refraction of the above-mentioned output layer The index is the same as or greater than the refractive index of the above-mentioned light-emitting element.

Owner:SEIKO EPSON CORP

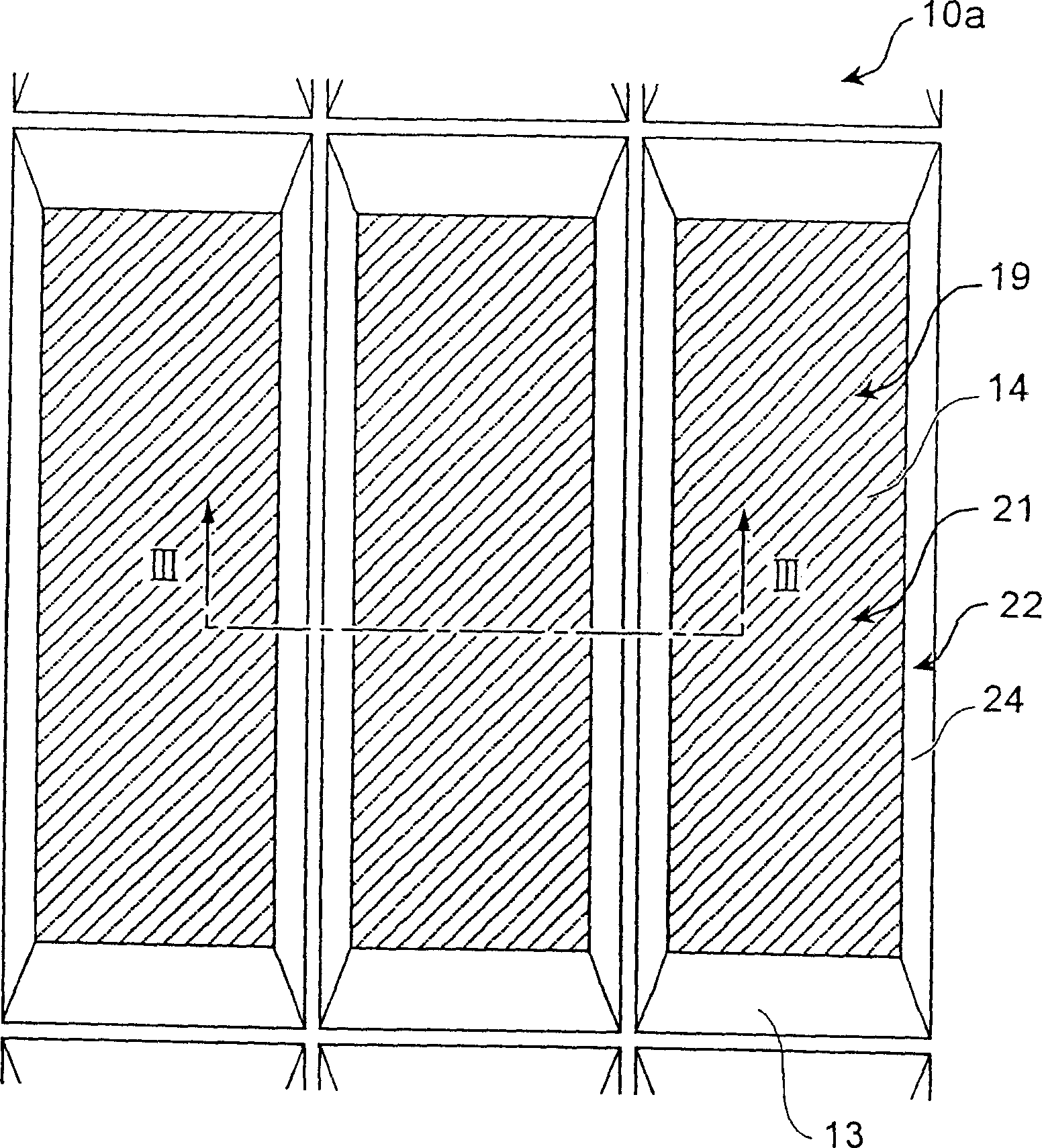

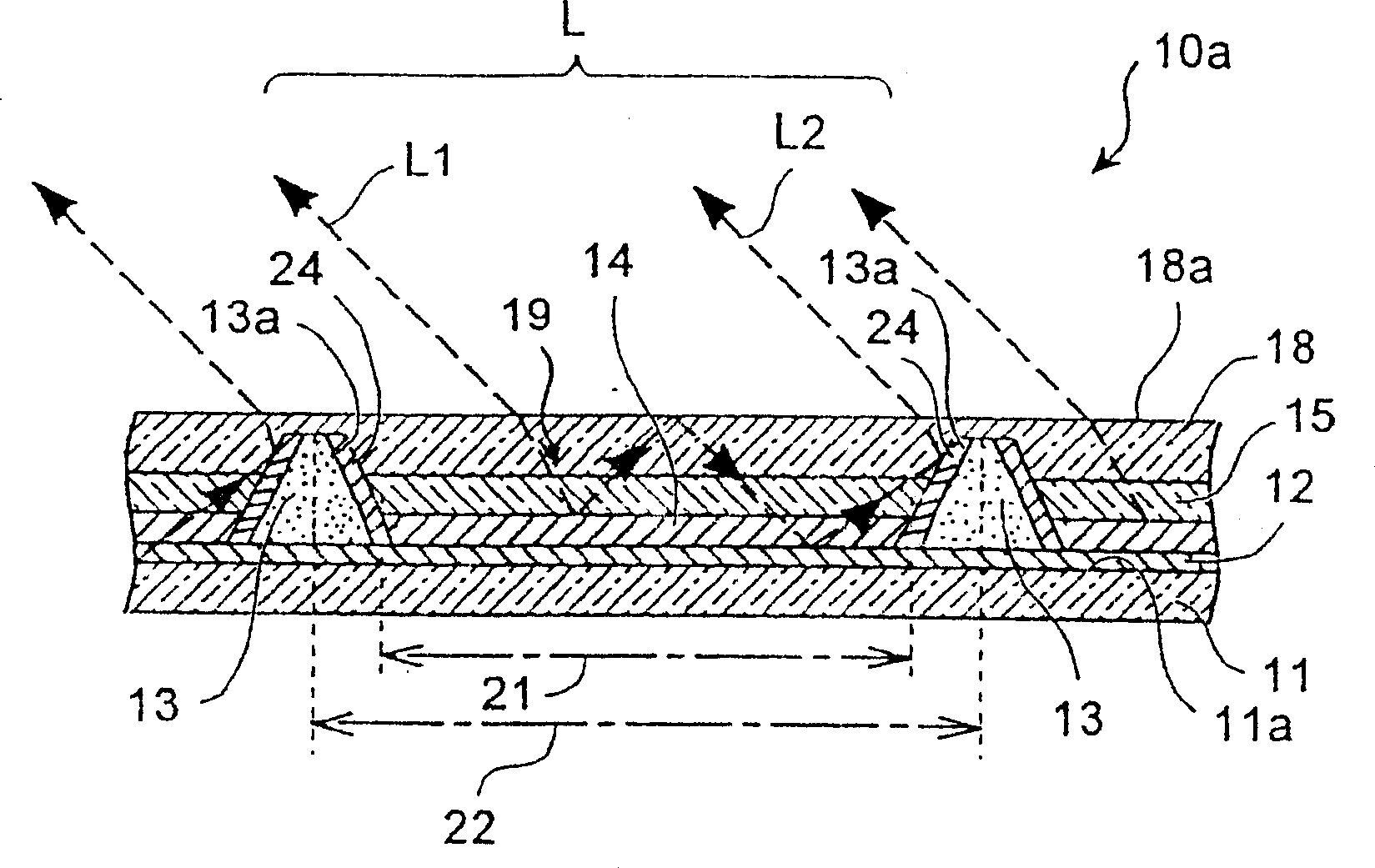

Displaying body, displaying panel and display

ActiveCN1499905AImprove take-out (extraction) efficiencyImprove production efficiencyElectric discharge tubesStatic indicating devicesOptical pathSurface plate

The invention provides a display panel having high light-extraction efficiency which can be easily produced. The present invention provides a display panel including an emission layer having a light-emitting layer and a transparent member (transmission layer) having recesses, an inclined surface of the recesses acting as a total reflection surface to reflect part of light radiated from the light-emitting layer. The display panel changes the optical path by total reflection, thus having no light-absorption loss and having high light-extraction efficiency. Since there is no need to deposit a reflecting film, it is easy to produce. Thus, a high-intensity display panel can be provided at low cost.

Owner:SEIKO EPSON CORP

Continuous Fractional Separation and Purification Method for Active Components of Star Anise

InactiveCN102260145AReduce dosageSolve operational difficultiesEther separation/purificationFermentationPurification methodsNatural product

The invention discloses a method for continuous fractional separation and purification of effective ingredients of star anise, and relates to purification of a natural product of star anise. The invention provides a method for continuous fractional separation and purification of the effective ingredients of the star anise, which can ensure the extraction efficiency of a target product, has low production operating cost, high solvent recovery rate and obviously low energy consumption, and is suitable for large-scale production. The method comprises the following steps of: extracting star aniseoil; extracting star anise oil resin; separating anethole from anisaldehyde; performing microbial conversion on shikimic acid; and extracting and separating the shikimic acid. On the basis of extracting the star anise oil resin and separating the anethole from the anisaldehyde, the shikimic acid is extracted and separated from extraction residue, products with high added value, such as shikimi fruit, the anethole and the anisaldehyde are obtained, and the extraction efficiency of the target product is ensured.

Owner:卢豪良

Hydrophobic low-eutectic-point solvent based on lidocaine and preparation method and extraction application of solvent

ActiveCN110270130AImprove performanceEasy to synthesizeLiquid solutions solvent extractionImino compound preparationMalachite greenMethyl violet

The invention discloses a hydrophobic low-eutectic-point solvent based on lidocaine and a preparation method and extraction application of the solvent, and belongs to the technical field of extraction, separation and enrichment of large cationic compounds. The hydrophobic low-eutectic-point solvent based on lidocaine is characterized in that the hydrophobic low-eutectic-point solvent is synthesized from lidocaine serving as a hydrogen bond acceptor and n-octyl p-hydroxybenzoate serving as a hydrogen bond donor in the molar ratio of 1:(0.25-3). The invention particularly discloses the preparation method of the hydrophobic low-eutectic-point solvent based on lidocaine and application of the solvent in extraction of rhodamine B, methyl violet or / and malachite green in an aqueous solution. When used as an extraction agent, the prepared hydrophobic low-eutectic-point solvent has the advantages of being easy to synthesize, stable in performance, low in toxicity, high in extraction efficiency and the like.

Owner:HENAN NORMAL UNIV

Production method of 2,3-dichloropyridine

ActiveCN102086174BAvoid problems that are prone to side effectsGuaranteed qualityOrganic chemistry3-AminopyridineFiltration

The invention relates to a production method of 2,3-dichloropyridine, solving the problem that byproducts are easily generated through 2-position chlorination reaction so as to cause the final product quality to be instable, for example, intermediate purification is carried out but yield and environment are influenced, and the working efficiency is reduced. The production method of the 2,3-dichloropyridine comprises the following steps: 1) carrying out degradation reaction: hydrolyzing 2-chloro nicotinamide used as a starting material, and carrying out solid-liquid separation to obtain 2-chlorine-3-aminopyridine; and (2) successively carrying out diazotization reaction and 3-position chlorination reaction: successively carrying out diazotization reaction and 3-position chlorination reaction on 2-chlorine-3-aminopyridine to obtain 2,3-dichloropyridine. The production method has the beneficial effects that (1) the difficulty that the byproducts are easily generated because 2-position chlorination is successfully avoided, thereby ensuring the quality of the intermediate product 2-chlorine-3-aminopyridine; and (2) because the intermediate product 2-chlorine-3-aminopyridine is not dissolved in strong basic aqueous solution, the product can be directly taken out by vacuum filtration, and is easy to purify.

Owner:南京广通医药化工有限责任公司

Method for preparing lactic acid and lactide through dehydration extraction

InactiveCN110845326AHigh purityEfficient removalCarboxylic compound separation/purificationBiotechnologyOrganic solvent

The invention relates to a method for preparing lactic acid and lactide through dehydration extraction. The method comprises the following steps: 1) mixing a crude lactic acid solution with an organicsolvent to obtain a mixed solution to be treated; and 2) evaporating and concentrating the to-be-treated mixed solution, removing moisture to obtain an organic solvent dissolved with lactic acid, andcarrying out extracting to obtain lactic acid in the organic solvent. The lactic acid production method is short in process route and convenient to operate, and the obtained lactic acid is high in purity. When the method is used for producing lactide, a high-quality lactide product can be obtained without complex processes such as lactic acid refining and the like; product yield is high, environmental pollution is small, and complex operation in a traditional lactide production process is avoided.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

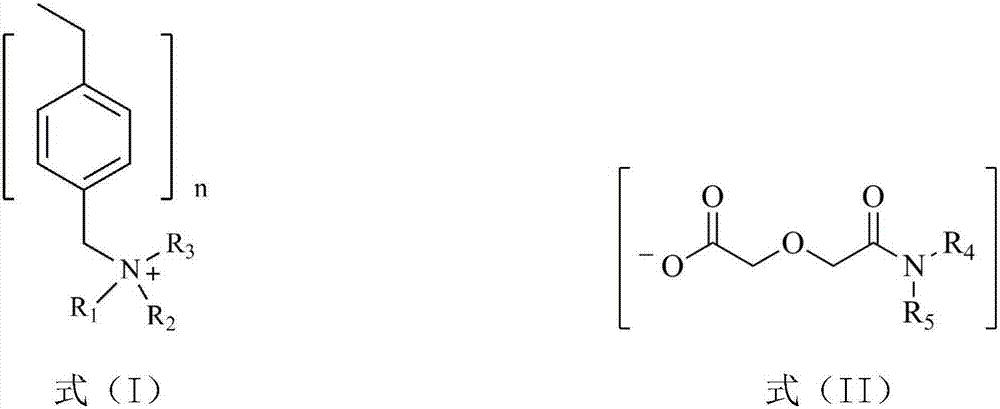

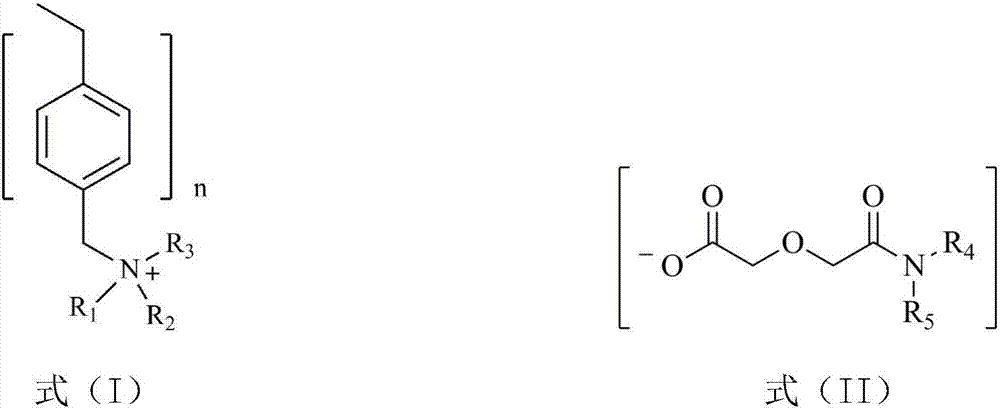

Solid-supported ionic liquid and preparation method thereof

ActiveCN107417815AGood effect of removing impuritiesOvercome churnProcess efficiency improvementRare earth ionsMethyl group

The invention provides a solid-supported ionic liquid and a preparation method thereof. The cations of the solid-supported ionic liquid are trialkyl benzyl ammonium cations as shown by a formula (I), and the anions of the solid-supported ionic liquid are deprotonated dialkyl diglycol amic acid as shown by a formula (II); in the formula (I), R1 and R2 are methyl, and R3 is methyl or ethoxyl; in the formula (II), R4 and R5 are respectively and independently alkyl, and at least one of the R4 and R5 is an alkyl group with at least 6 carbon atoms. According to the solid-supported ionic liquid and the preparation method thereof which are provided by the invention, the rare earth ions are extracted firstly, the impurity removal efficiency of iron and aluminum foreign ions is high, so that the recovery rate of low-concentration rare earth is high, and the utilization rate of rare earth resource is improved.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

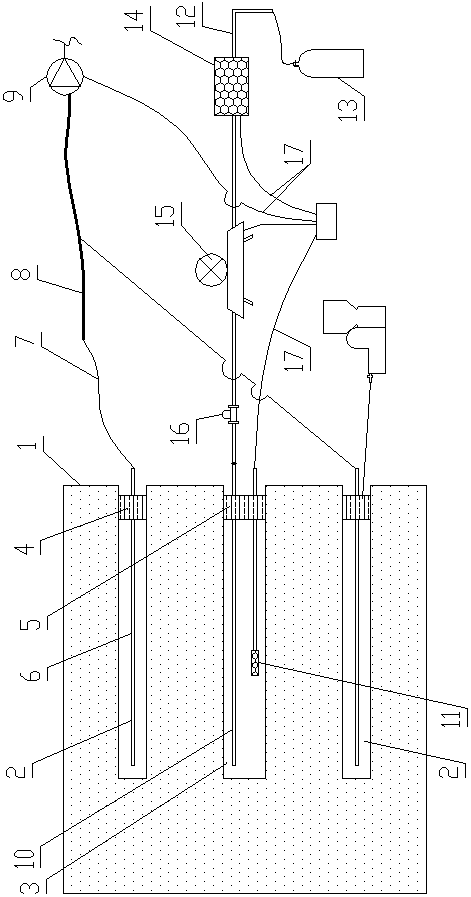

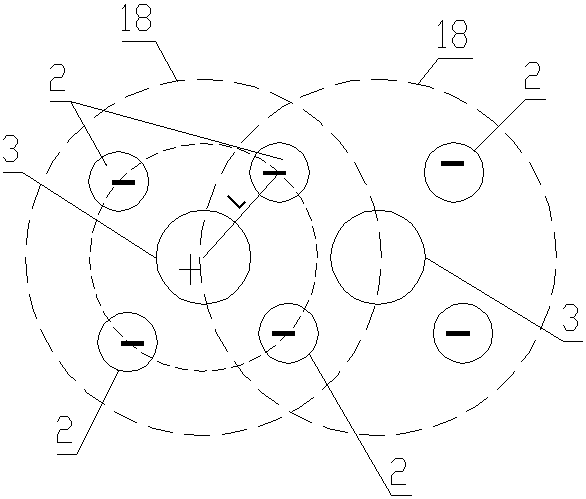

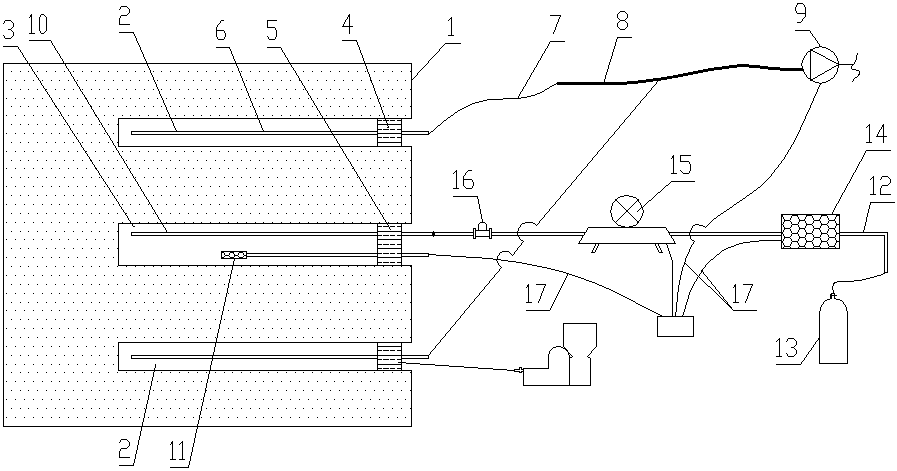

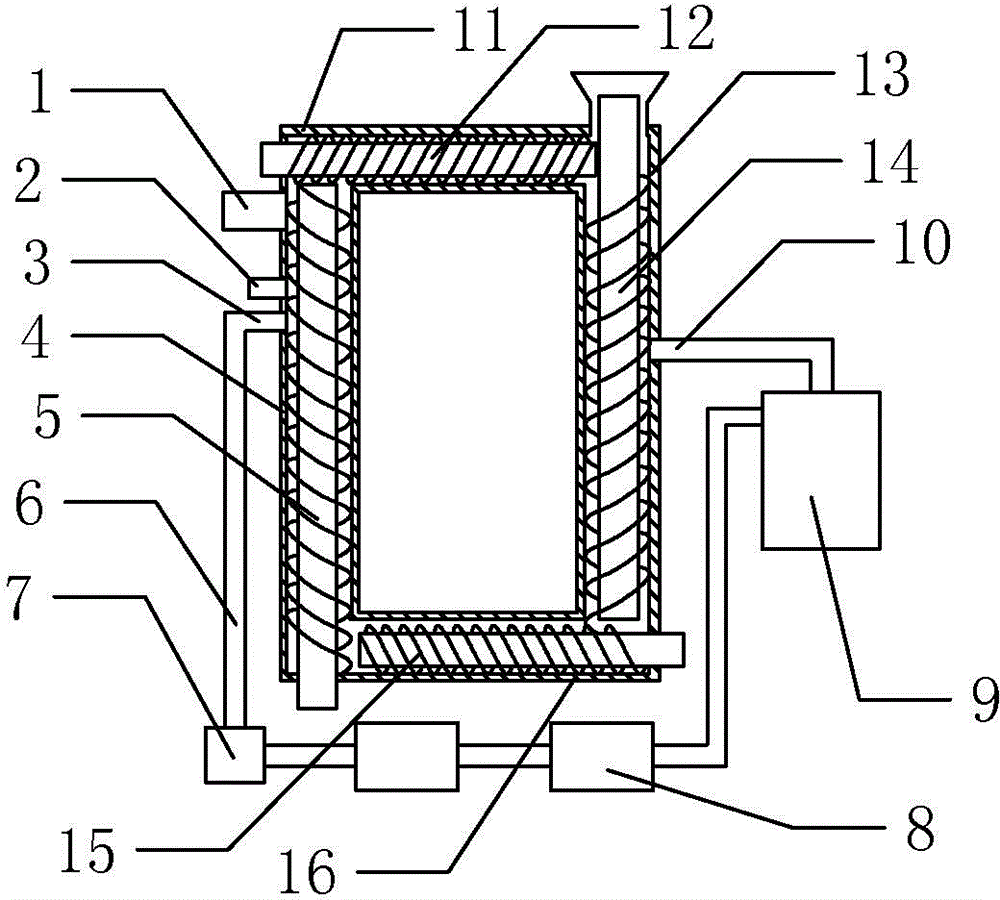

Supercritical carbon dioxide positive and negative pressure interaction combined gas extraction system and gas extraction method

PendingCN109989783AGood gas extraction effectImprove permeabilityInsulationFluid removalPositive airway pressureElectric heating

The invention discloses a supercritical carbon dioxide positive and negative pressure interaction combined gas extraction system. The system comprises a plurality of negative pressure holes evenly formed in a coal seam wall, and positive pressure holes are formed in areas defined by adjacent negative pressure holes. An extraction pipe is arranged in each negative pressure hole, extends out of a negative pressure hole sealing device and is connected with a negative pressure branch pipe, and the negative pressure branch pipes are connected with a negative pressure main pipe; a fracturing pipe and a carbon fiber quartz electric heating pipe are arranged in each positive pressure hole, each fracturing pipe extends out of a positive pressure hole packer, and the fracturing pipes are connected with a positive pressure main pipe; the positive pressure main pipe is connected with a gas storage tank, and a heating box, a booster pump and a pressure release valve are arranged on the positive pressure main pipe between the gas storage tank and the fracturing pipe in series. The invention further discloses a corresponding gas extraction method. The energy utilization rate is high, the supercritical state of carbon dioxide can be kept for a long time, and efficient gas extraction is achieved under the interaction of positive pressure and negative pressure.

Owner:HENAN POLYTECHNIC UNIV

Fresh spearmint seasoning oil and preparation method thereof

PendingCN113563962AImprove extraction efficiencyReduce energy consumptionFatty-oils/fats productionEdible oils/fatsGarlic OilSOYBEAN SEED OIL

The invention discloses fresh spearmint seasoning oil and a preparation method thereof. The preparation method comprises the following steps: (1) pretreatment: washing and draining fresh spearmint, and cutting the fresh spearmint into small sections; (2) drying: drying the small sections of spearmint at low temperature; (3) extraction: crushing the dried spearmint, then carrying out supercritical carbon dioxide extraction, and collecting extract liquor; (4) distillation: performing molecular distillation on the spearmint extract to obtain spearmint extract essential oil; and (5) mixing: mixing the obtained spearmint extract essential oil with ground sesame seed oil, garlic oil, fresh ginger oil and soybean oil according to a certain proportion to obtain the fresh spearmint seasoning oil. According to the method, low-temperature freeze drying, supercritical carbon dioxide extraction and molecular distillation are combined to extract the spearmint essential oil, so that the fresh color, aroma and taste and nutritional ingredients of the spearmint essential oil are reserved, and the shelf lifetime of the spearmint seasoning oil is prolonged while the fresh color, aroma and taste of the original spearmint essential oil is kept.

Owner:郑州雪麦龙食品香料有限公司

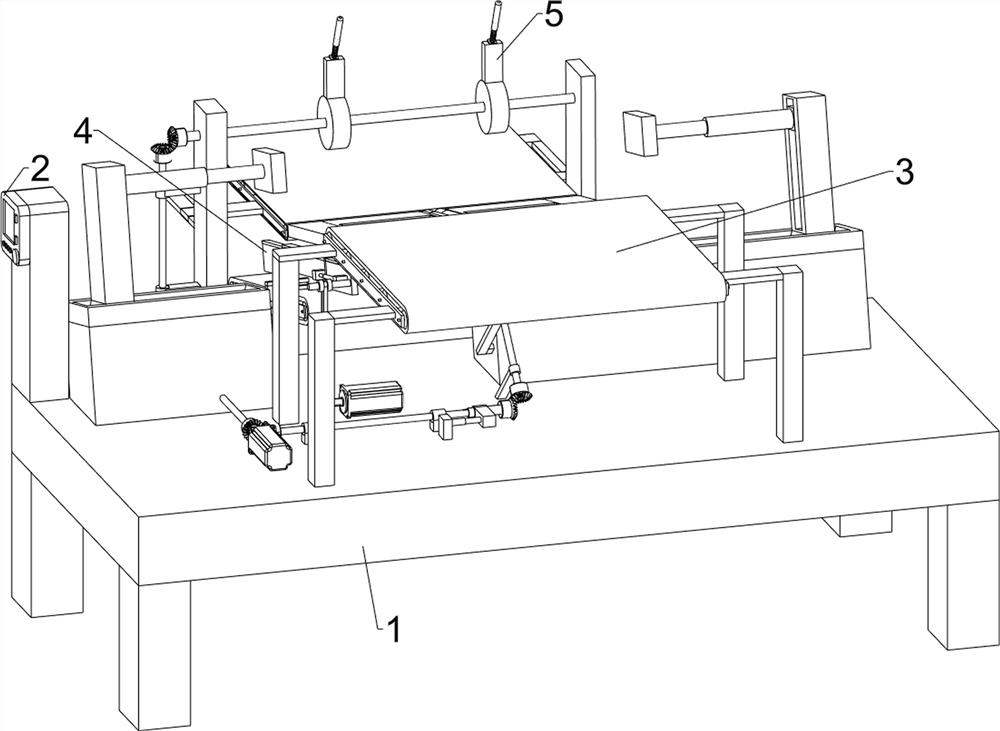

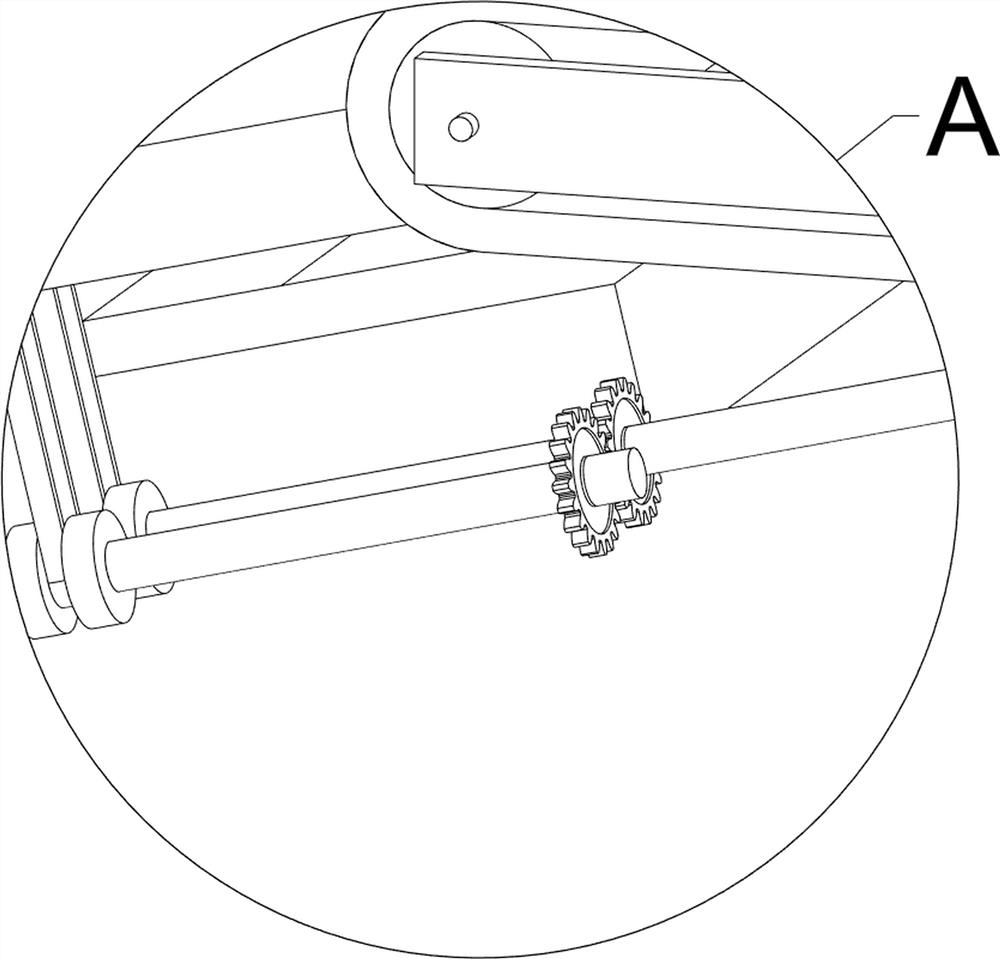

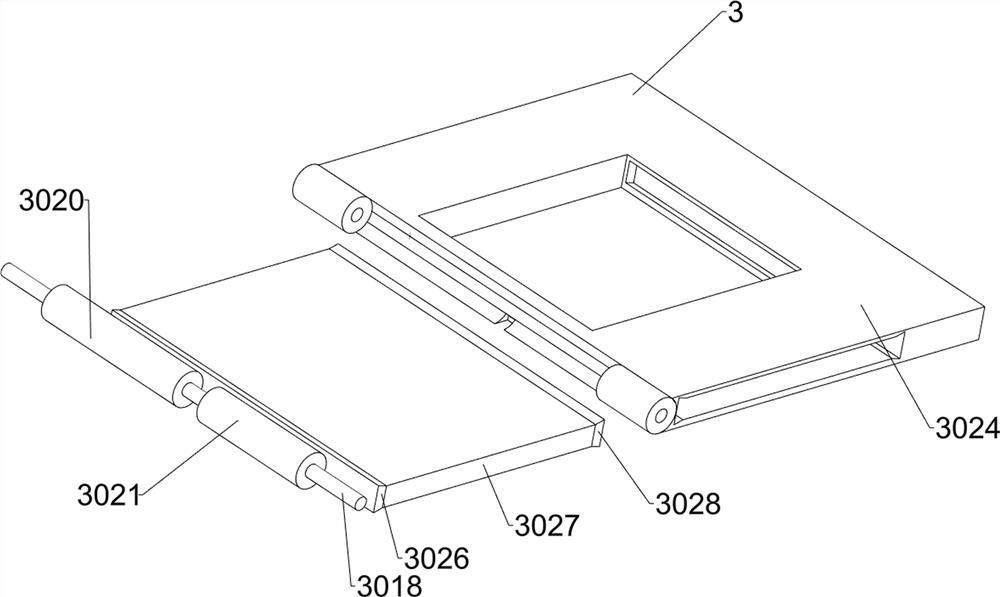

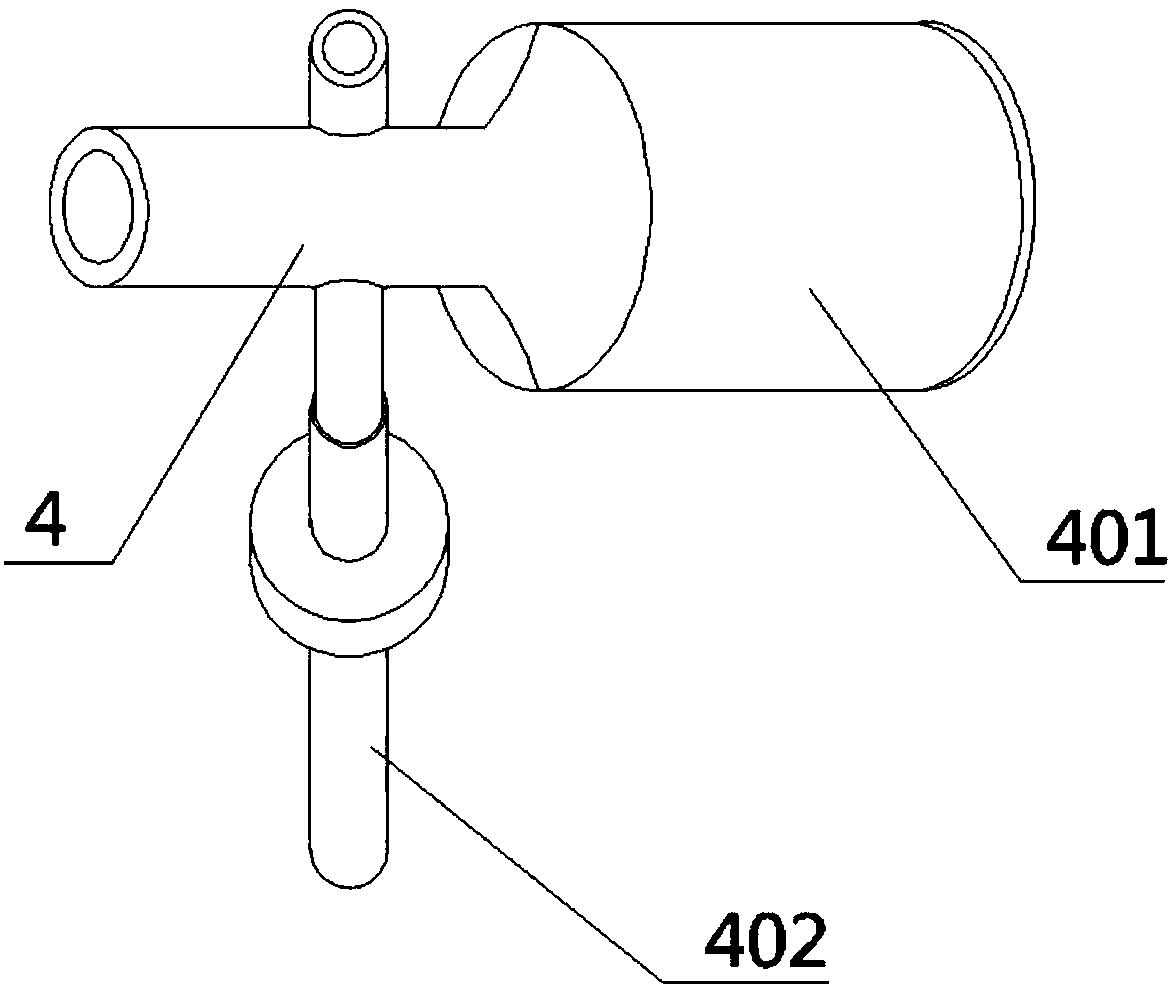

Device for taking out and layering cut water-retaining cotton in batches

InactiveCN112830285AEasy to scatterLow extraction efficiencyArticle deliveryArticle separationAgricultural engineeringMechanical engineering

The invention relates to the field of fresh flowers, in particular to a device for taking out and layering cut water-retaining cotton in batches. The invention aims to provide a device for taking out and layering cut water-retaining cotton in batches. According to the technical scheme, the device for taking out and layering the cut water-retaining cotton in batches comprises a bottom frame, a controller, a cotton piece taking-out mechanism, a piece separating mechanism and a leftover material collecting mechanism, wherein the cotton piece taking-out mechanism is connected with the leftover material collecting mechanism. When the device is used, the cut water-retaining cotton is taken out in batches, so that the taking-out efficiency is higher than that of manual work, and meanwhile, cotton piece scattering caused by a manual taking-out error is avoided; and cotton pieces are layered one by one and then conveyed backwards after being taken out, on the fresh flower processing water-retaining site, operation personnel can conveniently take out the cotton pieces one by one, and finally, leftover materials left after cutting are automatically collected, so that the manual treatment process is reduced, and the working efficiency is improved.

Owner:范伟群

Continuous movement type food extractor

InactiveCN104399279ACircular Motion RealizationAchieve separationSolid solvent extractionEngineeringTower

The invention discloses a continuous movement type food extractor. The continuous movement type food extractor comprises a left extracting tower and a right extracting tower which are vertically arranged, wherein an upper connecting pipe and a lower connecting pipe are arranged between the left extracting tower and the right extracting tower; a left spiral conveyor is arranged in the left extracting tower, a right spiral conveyor is arranged in the right extracting tower, an upper spiral conveyor is arranged in the upper connecting pipe, and a lower spiral conveyor is arranged in the lower connecting pipe; a dreg outlet, a first liquid-in pipe and a second liquid-in pipe are arranged on the side wall of the left extracting tower, a liquid-out pipe is arranged on the side wall of the right extracting tower, a circulating pipe is arranged between the second liquid-in pipe and the liquid-out pipe, an evaporator, a condenser and a liquid pump are arranged on the circulating pipe, the condenser is positioned between the evaporator and the liquid pump, the evaporator is adjacent to the liquid-out pipe, and a feeding pipe is arranged at the top end of the upper connecting pipe. The technical defects of low food extracting efficiency and complicated operation at present are overcome. The continuous movement type food extractor provided by the invention is high in efficiency and simple to operate.

Owner:CHONGQING TIANXINGZHAI PUERARIA THOMSONII FOOD CO LTD

Novel degreasing process of egg yolk powder

InactiveCN113214895AQuality improvementImprove extraction efficiencyFatty-oils/fats refiningFatty-oils/fats productionBiotechnologyYolk

The invention relates to a preparation method of defatted egg yolk powder. The method comprises the following steps: 1) granulating: adding 95% food-grade ethanol which accounts for 10-20% of the weight of the egg yolk powder into the egg yolk powder, and sieving with a sieve with the aperture of 5 mm to prepare cylindrical egg yolk powder particles with the particle size of 5 mm; 2) drying: drying the particles for 30-60 minutes under a dry and hot condition of 40-50 DEG C, wherein the granules are required to still contain ethanol which is not less than 2% of the weight of the granules; (3) charging: filling a charging barrel with the particles, and putting the charging barrel into an extraction kettle; 4) extracting: boosting the pressure, and starting extraction after reaching a stable state according to the main parameters of extraction that the extraction pressure is 20-27 Mpa, and the temperature is 32-50 DEG C, the flow rate is 80-320 L / h.kg, and the extraction time is 1-3 h; 5) separating: enabling the extracted mixed material to pass through a separation kettle, and settling, separating and precipitating the egg yolk oil at the bottom of the separation kettle, wherein the separation pressure is 4-6 MPa, and the temperature is 20-50 DEG C; and 6) discharging oil: discharging the separated egg yolk oil from an oil outlet at the bottom of the separation kettle every 15-30 minutes.

Owner:ZHEJIANG KANGLAITE PHARM CO LTD +1

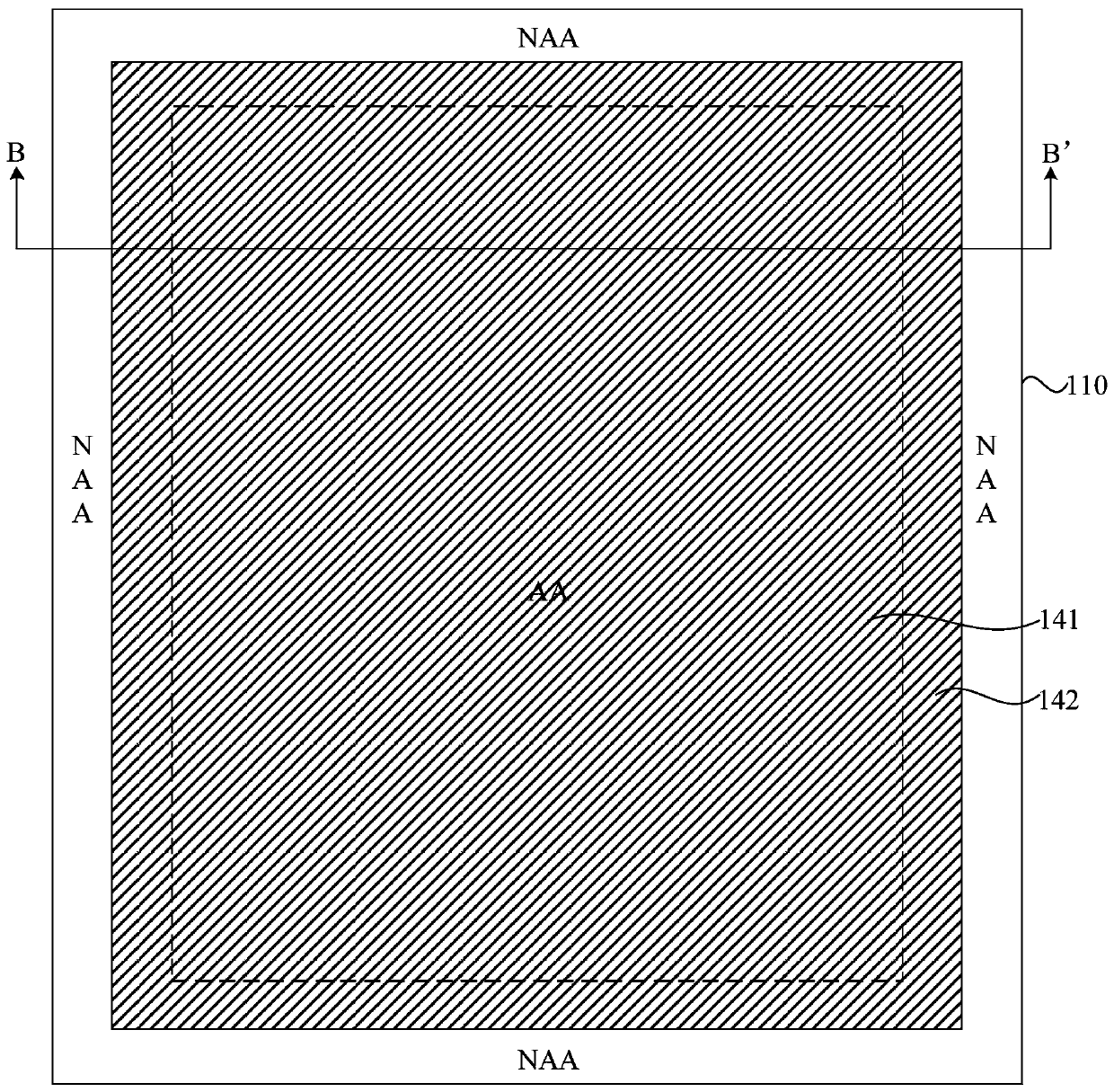

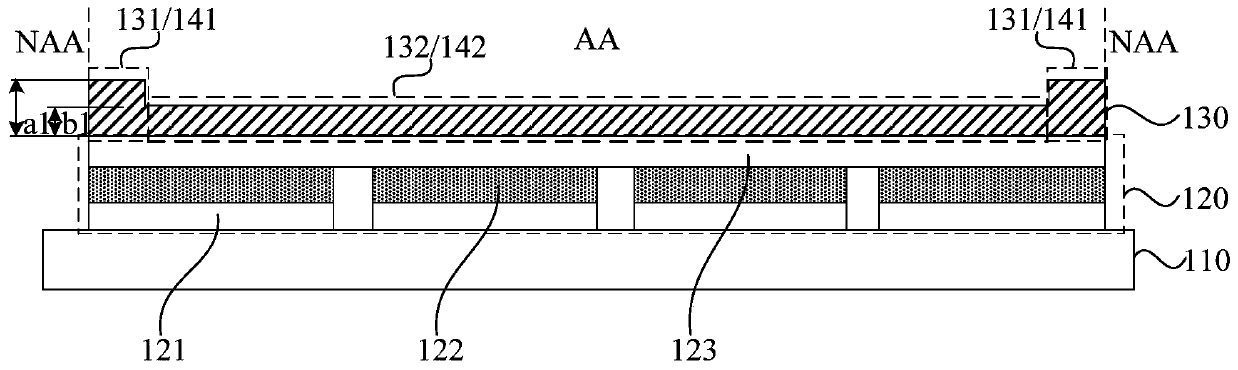

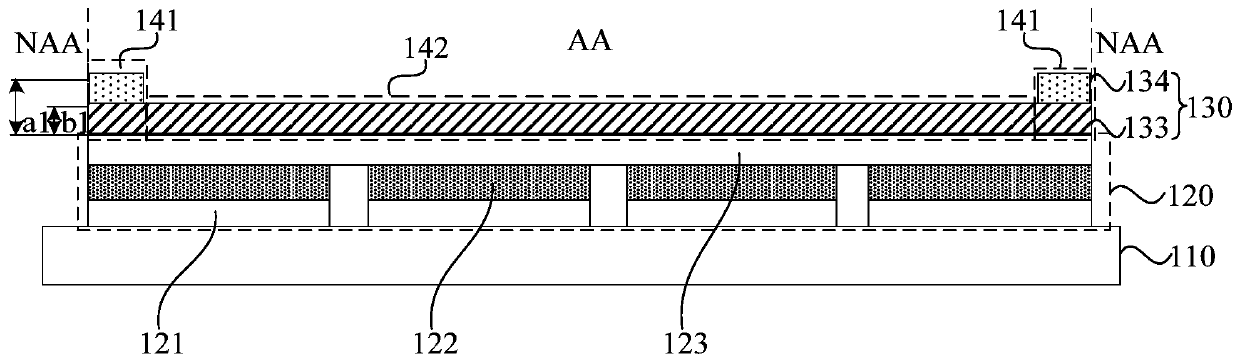

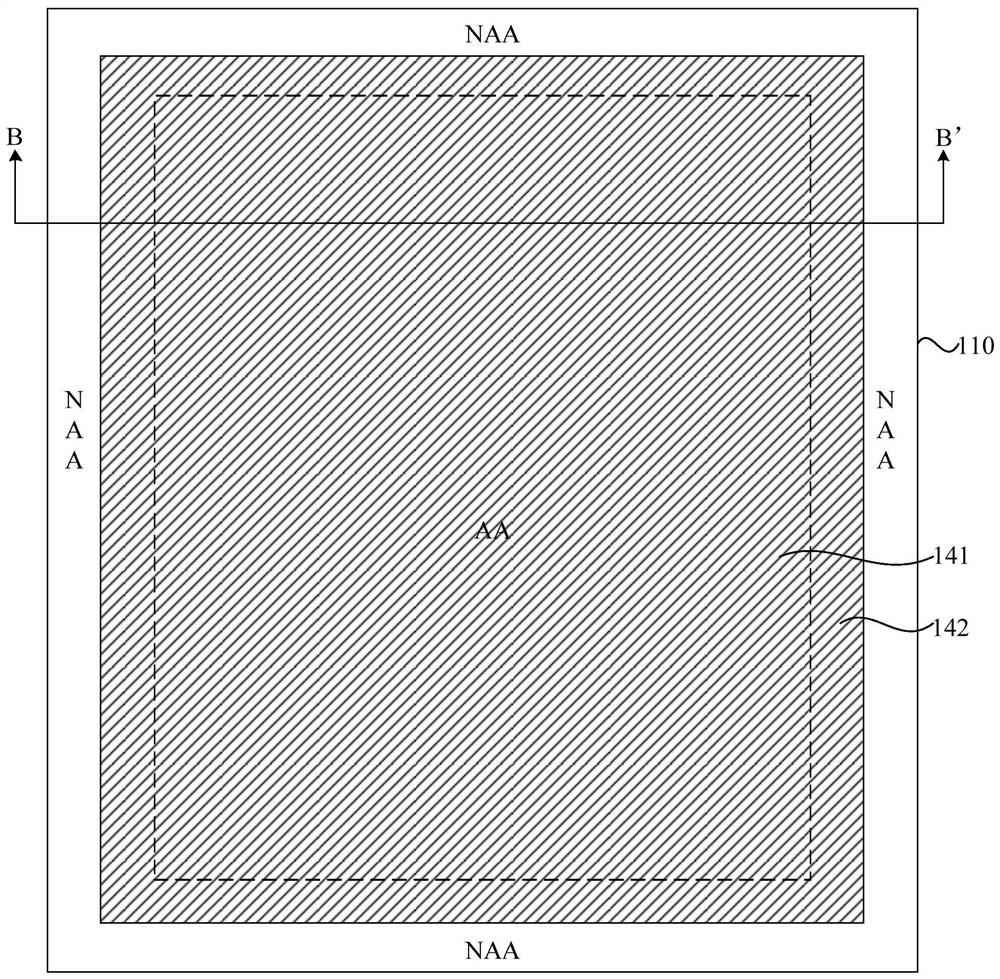

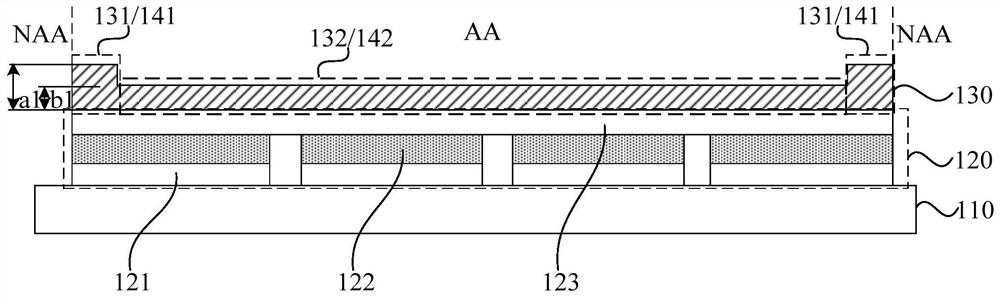

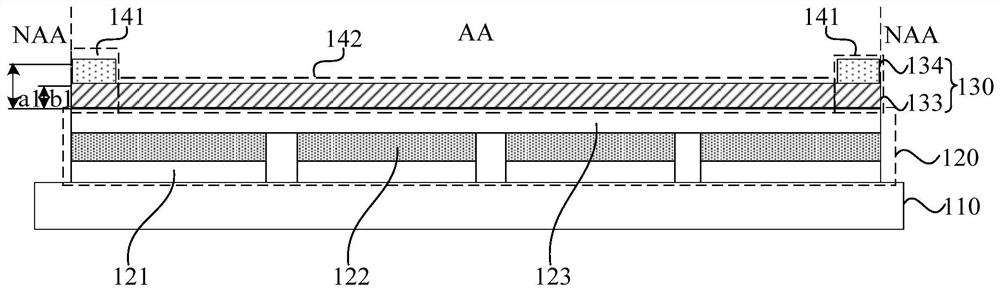

Display panel and manufacturing method thereof and display device

ActiveCN110416268AImprove display uniformityIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingEdge regionDisplay device

The invention discloses a display panel and a manufacturing method thereof and a display device. The display panel is divided into a display region and a non-display region surrounding the display region. The display region comprises an edge region and a non-edge region. The edge region of the display region is connected with the non-display region and surrounds the non-edge region. The display panel comprises a light extraction layer. The light extraction layer has a thickness at the edge region of the display region greater than the thickness at the non-edge region of the display region so that the light extraction efficiency in the edge region of the display region is enabled to be higher, the light extraction efficiency in the non-edge region of the display region is lower, then the light emergent from the edge region of the display region is enhanced by increasing the thickness of the light extraction layer in the edge region of the display region, the brightness of the edge region is increased, the brightness difference between the non-edge region and the edge region is reduced, the brightness of the edge region of the display panel and the brightness of the non-edge region tend to be the same, the display uniformity of the display panel is improved and the display effect is improved.

Owner:YUNGU GUAN TECH CO LTD

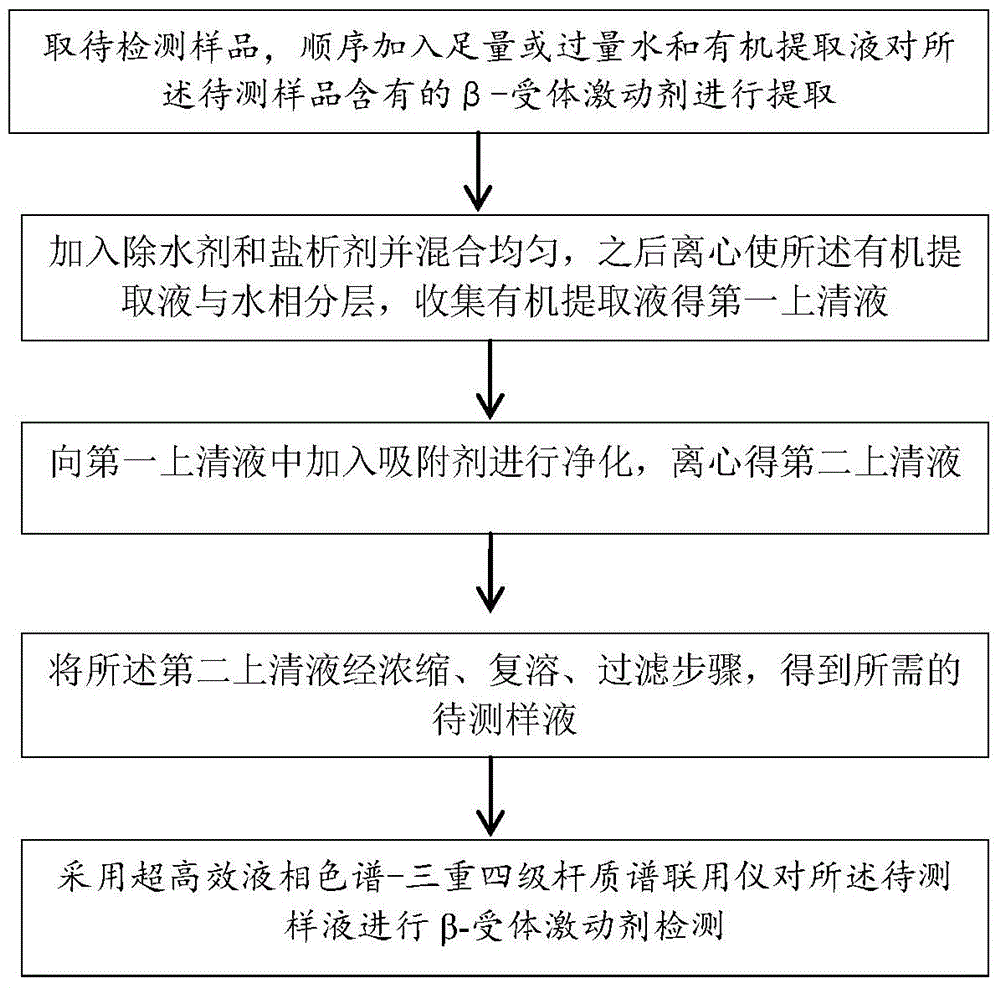

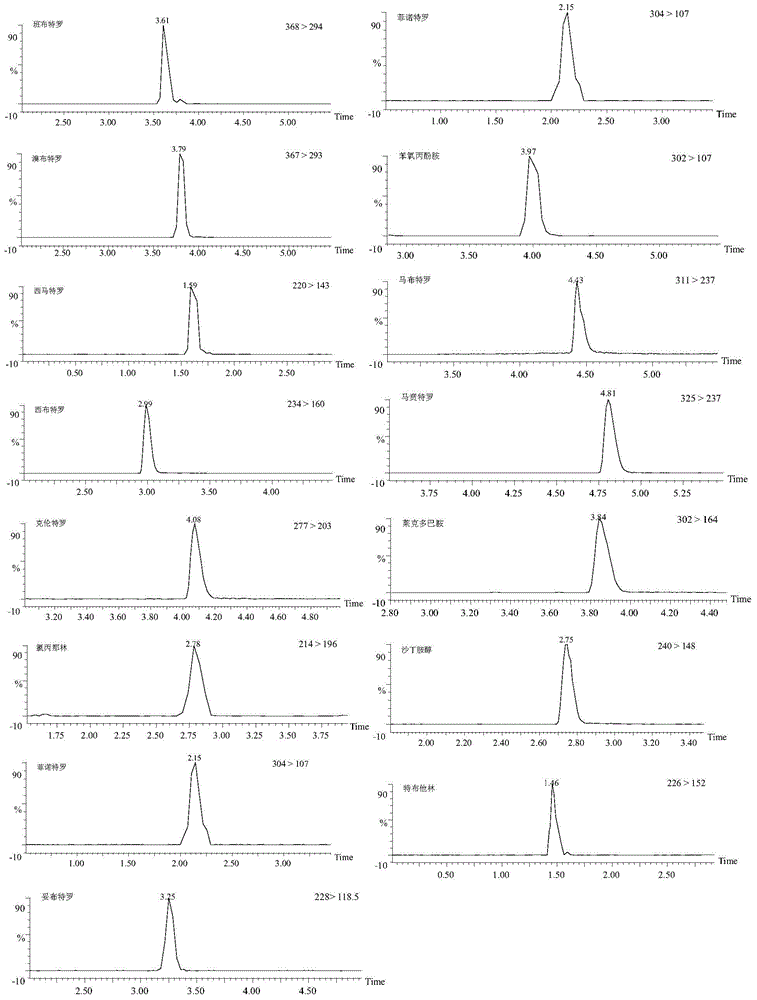

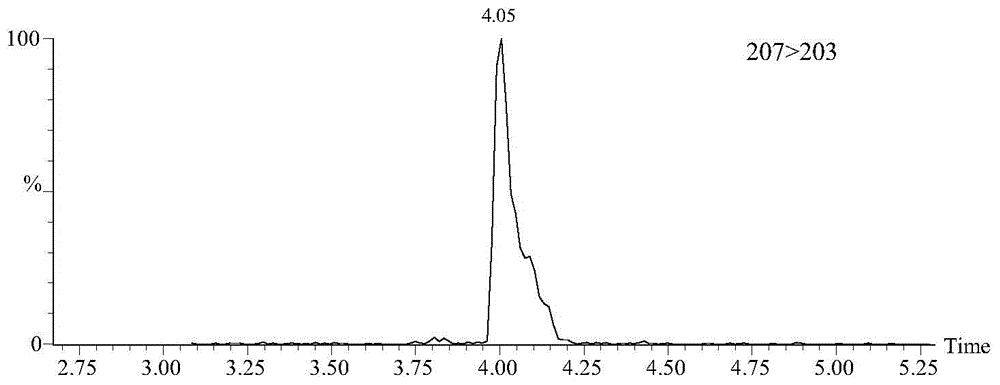

Liquid chromatography-mass spectrometry method for rapidly detecting content of beta-agonists and sample pretreatment method

The invention provides a liquid chromatography-mass spectrometry method for rapidly detecting the content of beta-agonists. The liquid chromatography-mass spectrometry method comprises the following steps: pretreating a sample, namely, sequentially adding water and an organic extracting solution in the sample for extracting a beta-receptor stimulant; then adding a salting-out agent and a water removing agent to ensure that the organic extracting solution and a water phase demix, centrifuging to obtain a first supernate, adding an adsorbing agent in the first supernate for purification, centrifuging to obtain a second supernate, concentrating, re-dissolving and filtering the second supernate to prepare a sample to be detected; and then detecting the beta-receptor stimulant contained in an animal-derived food by adopting an ultra-high performance liquid chromatography-triple quadrupole mass spectrometer. According to the sample pretreatment method suitable for liquid chromatography-mass spectrometry detection, provided by the invention, interfering molecules are removed through extraction and purification so that high accuracy is achieved in sample detection.

Owner:BEIJING ENTRY EXIT INSPECTION & QUARANTINE BUREAU INSPECTION & QUARANTINE TECH CENT

Method for continuous fractional separation and purification of effective ingredients of star anise

InactiveCN102260145BLow extraction efficiencyReduce production and operation costsEther separation/purificationFermentationNatural productAdditive ingredient

The invention discloses a method for continuous fractional separation and purification of effective ingredients of star anise, and relates to purification of a natural product of star anise. The invention provides a method for continuous fractional separation and purification of the effective ingredients of the star anise, which can ensure the extraction efficiency of a target product, has low production operating cost, high solvent recovery rate and obviously low energy consumption, and is suitable for large-scale production. The method comprises the following steps of: extracting star aniseoil; extracting star anise oil resin; separating anethole from anisaldehyde; performing microbial conversion on shikimic acid; and extracting and separating the shikimic acid. On the basis of extracting the star anise oil resin and separating the anethole from the anisaldehyde, the shikimic acid is extracted and separated from extraction residue, products with high added value, such as shikimi fruit, the anethole and the anisaldehyde are obtained, and the extraction efficiency of the target product is ensured.

Owner:卢豪良

A kind of cobalt extraction method in tailings

ActiveCN105567956BReasonable and innovative method designImprove utilization efficiencyProcess efficiency improvementCobaltImpurity

The invention discloses a method for extracting cobalt from tailings. After termination, add alkali to remove excess inorganic acid impurities; (2) separate the mixture obtained in step (1) from solid to liquid, and take out all the separated liquid as mixed liquid I for later use; (3) separate the solid obtained from step (2) from solid to liquid The tailings powder is crushed to a maximum particle size of 0.8-1.6mm, and the pulverized tailings powder is added to an inorganic acid solution for leaching. After the leaching reaction is terminated, alkali is added to remove excess inorganic acid impurities; (4) the mixture obtained in step (3) Separation of solid and liquid, take out all the separated liquid as mixed liquid II for later use. The invention has the advantages that it can overcome the disadvantages of the prior art, and the method design is reasonable and novel.

Owner:HEBEI UNIV OF ENG

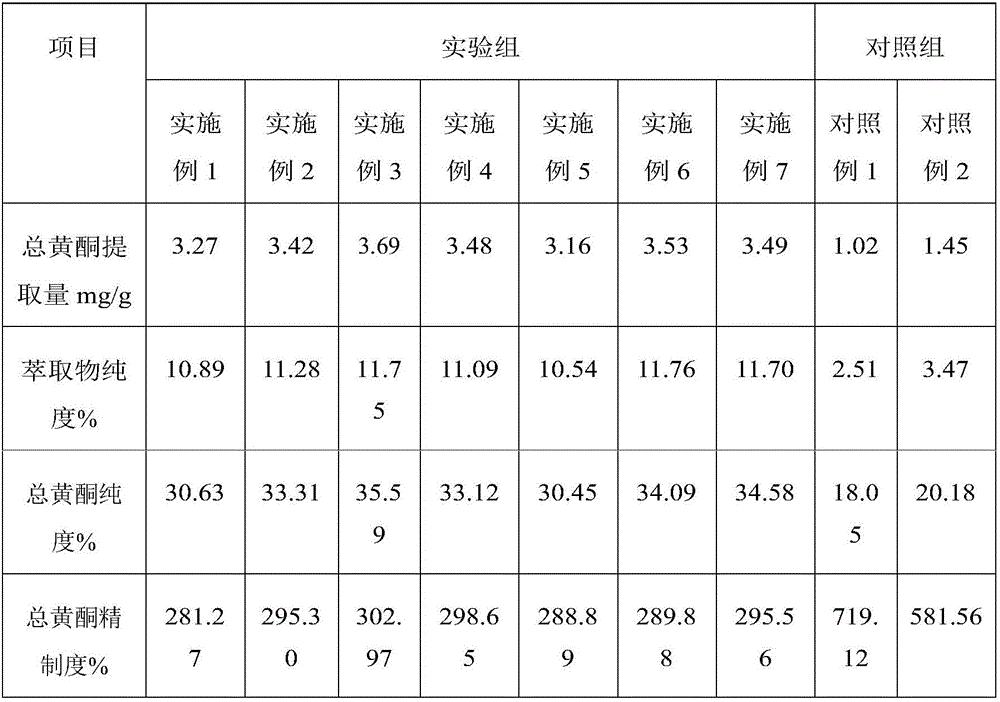

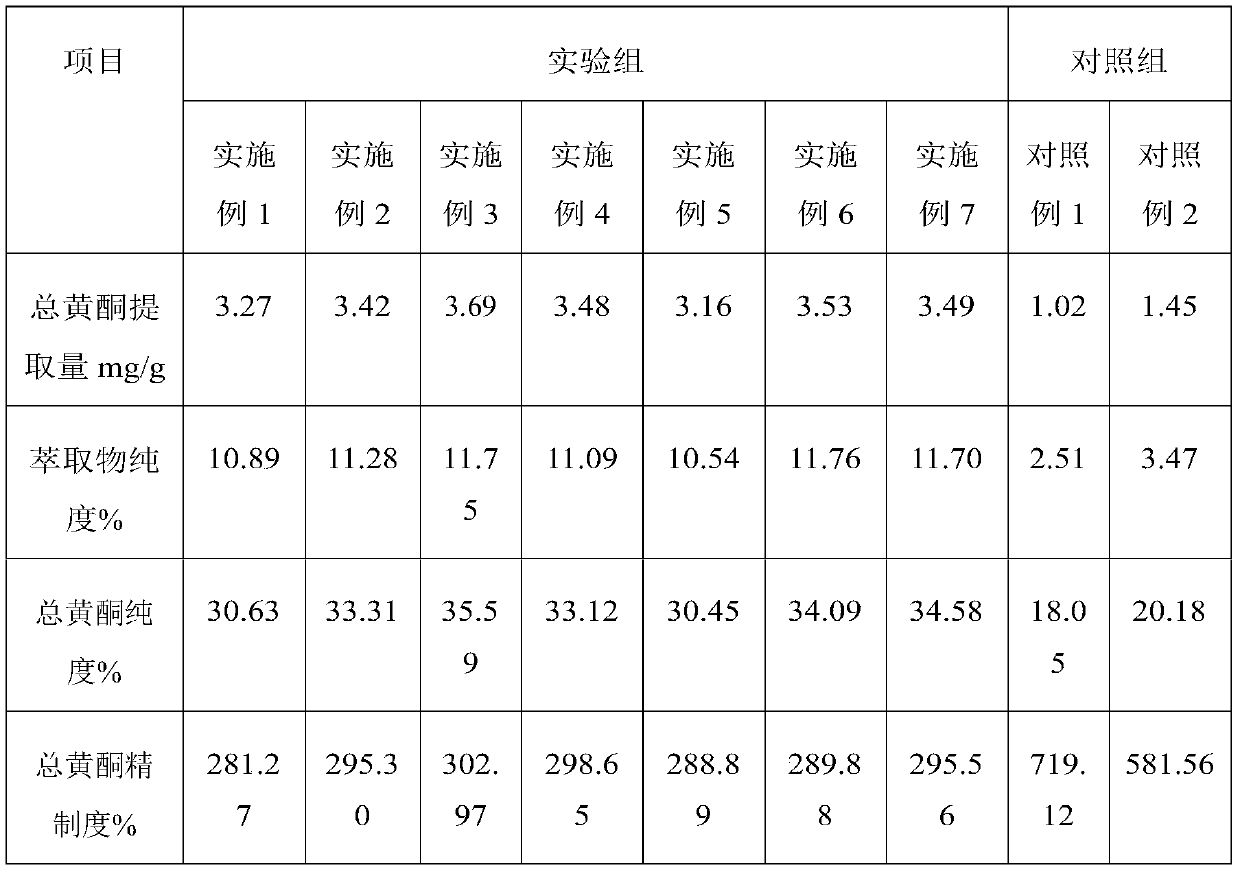

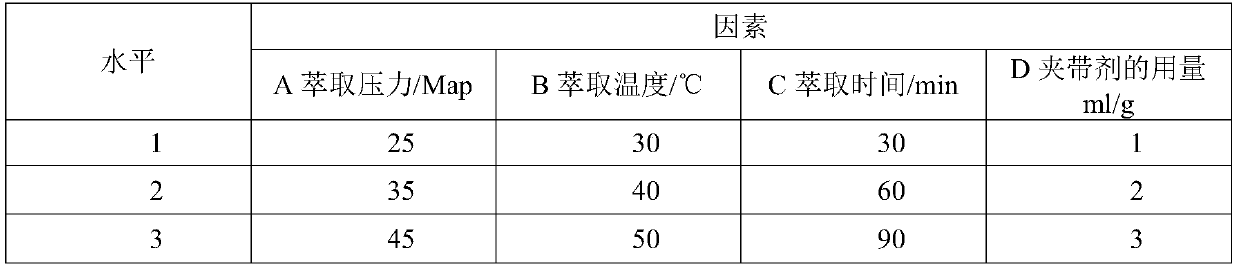

Preparation method of lespedeza total flavone

ActiveCN105832809ANo residueNo pollution in the processDigestive systemAntinoxious agentsOrganic solventElution

The invention provides a preparation method of lespedeza total flavone. The preparation method comprises the following steps: an extraction step: taking lespedeza powder, and extracting the lespedeza powder by adopting a supercritical fluid extraction method by taking supercritical fluid CO2 as an extracting agent and an organic solvent as an entrainer to obtain a lespedeza extract; and a purification step: purifying the lespedeza extract by adopting an adsorption chromatography, performing elution by using an organic solvent mixed solution as an eluting agent to obtain an eluant, and then removing the eluting agent from the eluant to obtain lespedeza total flavone. According to the method, the supercritical fluid extraction method is adopted to extract the lespedeza powder, so that double effects of extraction and separation can be achieved, and the extraction efficiency is high; and the adsorption chromatography is adopted to separate the obtained extract, so that the impurities in the extract can be effectively removed, flavone active substances in lespedeza can be kept, the separation efficiency is high, and the obtained lespedeza total flavone is high in purity.

Owner:GRASSLAND RES INST OF CHINESE ACAD OF AGRI SCI

Hydrophobic deep eutectic solvent based on lidocaine and its preparation method and application

ActiveCN110270130BImprove performanceEasy to synthesizeLiquid solutions solvent extractionImino compound preparationBenzoic acidSolvent

The invention discloses a lidocaine-based hydrophobic deep eutectic solvent, a preparation method and application thereof, and belongs to the technical field of extraction, separation and enrichment of large cationic compounds. The main points of the technical scheme of the present invention are: a hydrophobic deep eutectic solvent based on lidocaine, which uses lidocaine as a hydrogen bond acceptor and n-octyl p-hydroxybenzoate as a hydrogen bond The donor is synthesized according to the molar ratio of 1:0.25~3. The invention also specifically discloses the preparation method of the lidocaine-based hydrophobic deep eutectic solvent and its application in extracting rhodamine B, methyl violet or / and malachite green in aqueous solution. When the hydrophobic deep eutectic solvent prepared by the invention is used as an extractant, it has the advantages of simple synthesis, stable performance, low toxicity, high extraction efficiency and the like.

Owner:HENAN NORMAL UNIV

Process for extraction refining amygdalin

The invention provides a process for extraction refining amygdalin which consists of, disintegrating the plant raw material containing rich bitter apricot seed into powder, removing the grease from the raw material powder by using CO2 as extracting agent, carrying out decompression segregation to the carbon dioxide containing vegetable fat, charging alcohol into ground-slag containing bitter apricot seed glycosides by the solid-to-liquid ratio of 1 : 3-10, agitating, filtering by suction to obtain the filter liquor, distilling and drying the filter liquor to obtain crude product of bitter apricot seed glycoside, dissolving the bitter apricot seed glycoside into ethanol, low temperature crystallizing, filtering and drying to obtain the high purity bitter apricot seed glycosides.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

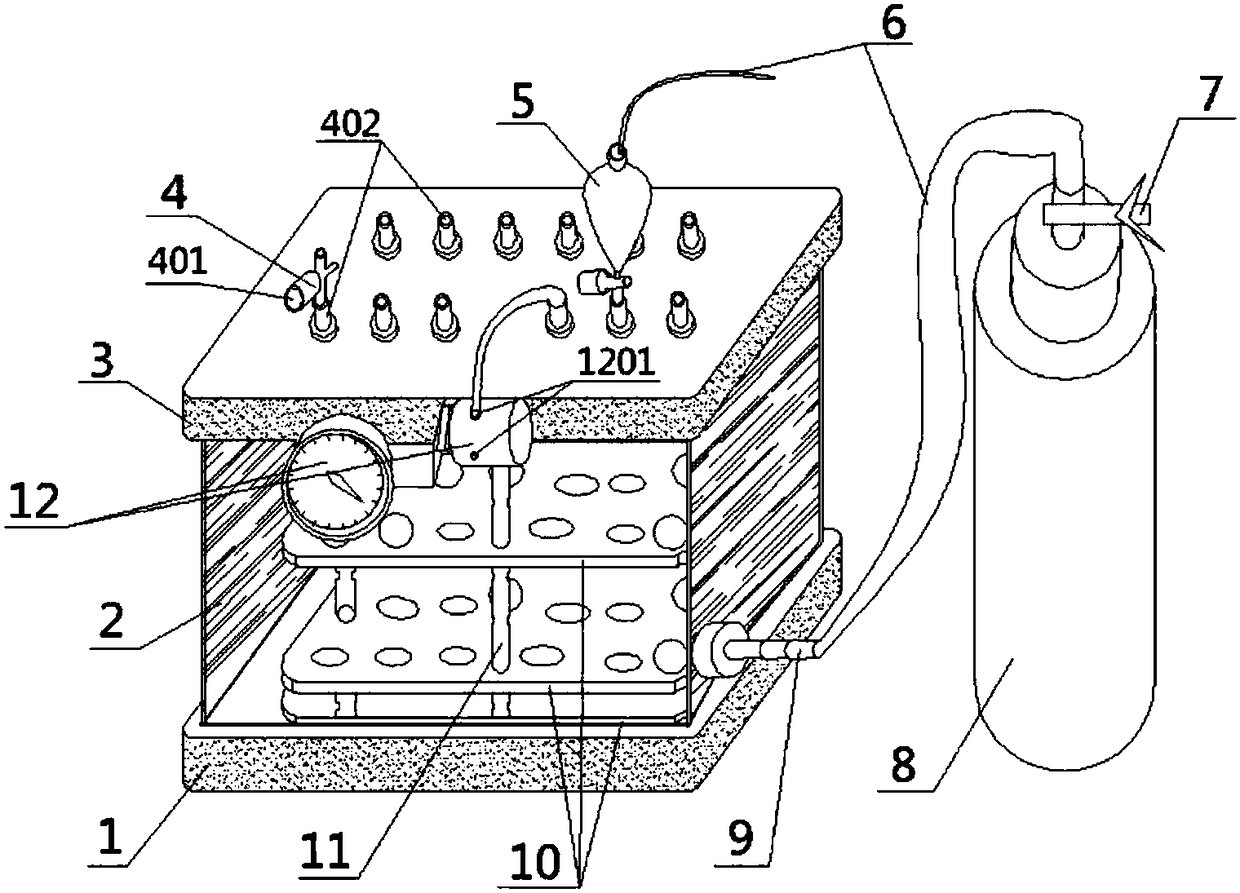

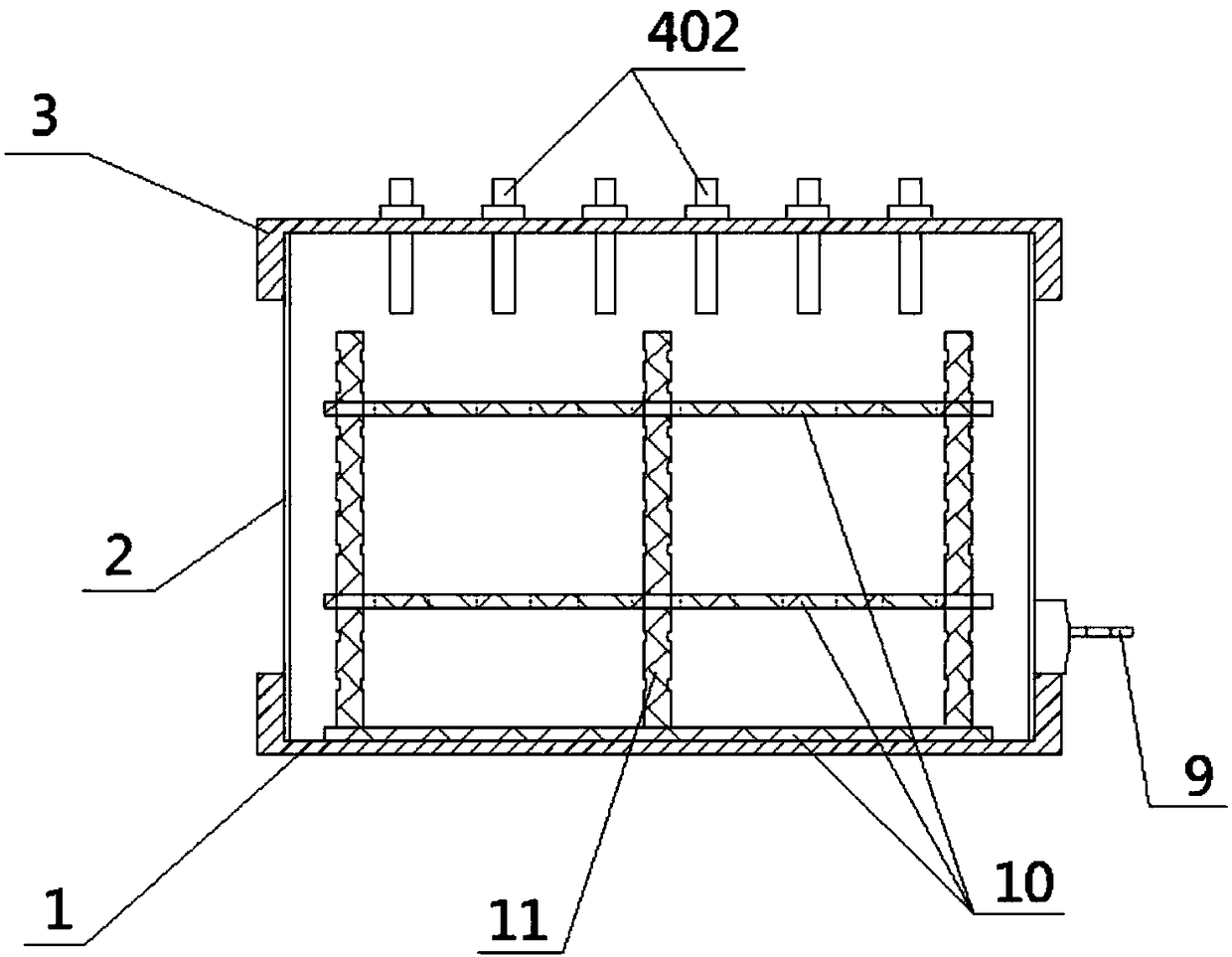

Gas boiling stabilization type extraction device

InactiveCN108379874AFully contactedExtended extraction timeLiquid solutions solvent extractionBottleChemical engineering

The invention discloses a gas boiling stabilization type extraction device. The gas boiling stabilization type extraction device is characterized by comprising a fixed bottom plate, an upper cover plate, a glass framework, a gas inlet device, a gas bottle, a gas pipe, a gas flow control device, a bracket, a positioning stand column, an extraction bottle and a connecting and positioning plug pipe,wherein the glass framework is mounted between the fixed bottom plate and the upper cover plate; the gas inlet device is mounted on a side face of the glass framework; the connecting and positioning plug pipe is mounted on the upper surface of the upper cover plate; the extraction bottle is mounted on the connecting and positioning plug pipe; the positioning stand column is mounted on the upper surface of the fixed bottom plate; the bracket is mounted on the upper surface of the positioning stand column; the positioning stand column and the bracket are located in the glass framework; the gas bottle is mounted between the gas inlet device and the connecting and positioning plug pipe; the gas flow control device is mounted at an outer side of a contact part of the upper cover plate and the glass framework; the gas flow control device is connected with the gas pipe. The gas boiling stabilization type extraction device disclosed by the invention can be used for introducing gas into the extraction bottle, a solution in the extraction bottle has a gas boiling state and the extraction bottle does not need to be shaken; the gas boiling stabilization type extraction device is convenient touse and has a good extraction effect and a rapid speed.

Owner:安徽奥创环境检测有限公司

Display panel, manufacturing method thereof, and display device

ActiveCN110416268BImprove display uniformityIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

Owner:YUNGU GUAN TECH CO LTD

A kind of preparation method of total flavonoids of ramie

ActiveCN105832809BNo residueNo pollution in the processDigestive systemAntinoxious agentsOrganosolvLespedeza bicolor

The invention provides a preparation method of lespedeza total flavone. The preparation method comprises the following steps: an extraction step: taking lespedeza powder, and extracting the lespedeza powder by adopting a supercritical fluid extraction method by taking supercritical fluid CO2 as an extracting agent and an organic solvent as an entrainer to obtain a lespedeza extract; and a purification step: purifying the lespedeza extract by adopting an adsorption chromatography, performing elution by using an organic solvent mixed solution as an eluting agent to obtain an eluant, and then removing the eluting agent from the eluant to obtain lespedeza total flavone. According to the method, the supercritical fluid extraction method is adopted to extract the lespedeza powder, so that double effects of extraction and separation can be achieved, and the extraction efficiency is high; and the adsorption chromatography is adopted to separate the obtained extract, so that the impurities in the extract can be effectively removed, flavone active substances in lespedeza can be kept, the separation efficiency is high, and the obtained lespedeza total flavone is high in purity.

Owner:GRASSLAND RES INST OF CHINESE ACAD OF AGRI SCI

A method for ultrasonically intensified recovery of sulfur, lead, zinc and silver from oxygen-enriched direct leaching slag of zinc concentrate or lead-zinc mixed ore

ActiveCN104195344BIncrease throughputReduce processingSulfur compoundsProcess efficiency improvementTetrachloroethyleneSulfur product

The invention discloses a method for recovering sulfur, lead, zinc and silver from oxygen-rich direct leaching residues of zinc concentrate or lead and zinc mixed ores by virtue of ultrasonic wave intensification, belonging to the field of comprehensive recycling of non-ferrous metal metallurgy. The method disclosed by the invention comprises the following steps: by using tetrachloroethylene or trichloro ethylene as a solvent, extracting elemental sulfur from the oxygen-rich direct leaching residues of zinc concentrate or lead and zinc mixed ores, which are dried, ground, and sieved by virtue of ultrasonic wave intensification, preserving heat and filtering, after naturally cooling and forcibly cooling the filtrate and filtering to obtain a sulfur product, and returning a regenerated sulfur extraction agent to a sulfur extraction step; and enriching zinc, lead and silver in the residues, wherein the residues can be directly fed to a lead system to recover zinc, lead and silver, or the residues are firstly leached to recover zinc, filter residues are fed to the lead system to recover silver, and zinc-containing filtrate is returned to a direct leaching system. The method disclosed by the invention is simple, energy-saving and high in sulfur recovery rate and product quality. The sulfur extraction process is sealed, so that the method is free from environmental pollution and is particularly suitable for comprehensively utilizing normal pressure / high pressure oxygen-rich direct leaching residues of zinc concentrate or lead and zinc mixed ores.

Owner:株洲起源科技有限责任公司

Method for extracting cobalt from tailings

ActiveCN105567956AReasonable and innovative method designImprove utilization efficiencyProcess efficiency improvementCobaltImpurity

The invention discloses a method for extracting cobalt from tailings. The method includes steps: (1) grinding the tailings into powder with a maximum partial diameter being 1-2mm, adding the ground tailings into an inorganic acid solution to realize leaching, and adding alkali to remove excessive inorganic acid impurities after leaching reaction is finished; (2) subjecting a mixture obtained at the step (1) to solid-liquid separation, and taking out the completely separated liquid which is mixed liquid I for standby application; (3) grinding solid tailing powder obtained by solid-liquid separation at the step (2) into powder with a maximum partial diameter being 0.8-1.6mm, adding the ground tailings into the inorganic acid solution to realize leaching, and adding alkali to remove excessive inorganic acid impurities after leaching reaction is finished; (4) subjecting a mixture obtained at the step (3) to solid-liquid separation, and taking out the completely separated liquid which is mixed liquid II for standby application. The method for extracting the cobalt from the tailings has the advantages that defects of the prior art can be overcome, and the method is reasonable and novel in design.

Owner:HEBEI UNIV OF ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com