Supercritical carbon dioxide positive and negative pressure interaction combined gas extraction system and gas extraction method

A carbon dioxide and gas drainage technology, which is applied in the direction of gas discharge, mining fluids, mining equipment, etc., can solve the problems of increasing extraction costs, energy can not be concentrated, etc., and achieve a good effect of gas extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

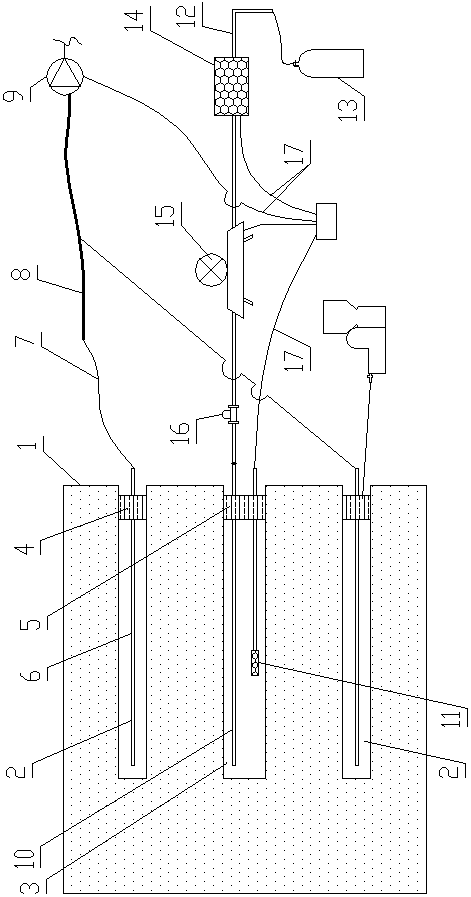

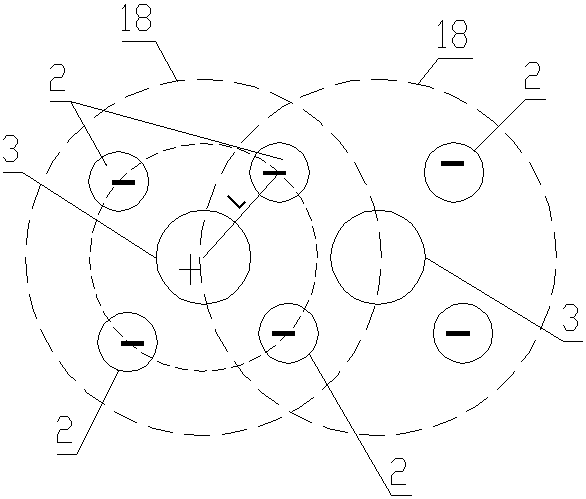

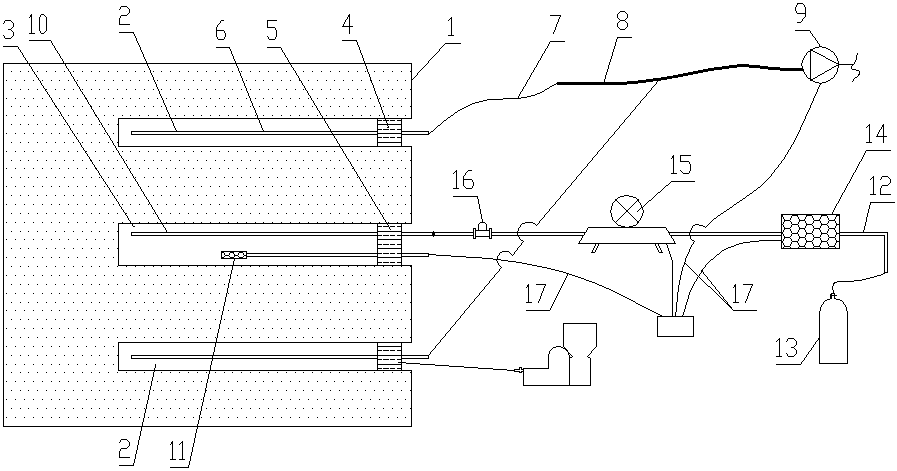

[0041] Such as figure 1 and figure 2 As shown, the supercritical carbon dioxide combined positive and negative pressure interaction combined drainage gas system of the present invention includes a plurality of negative pressure holes 2 uniformly arranged on the coal seam wall 1, and positive pressure holes 2 are arranged in the area surrounded by adjacent negative pressure holes 2. The pressure hole 3; the negative pressure hole 2 is provided with a negative pressure hole sealer 4, and the positive pressure hole 3 is provided with a positive pressure hole sealer 5;

[0042] A extraction pipe 6 is arranged in the negative pressure hole 2, and the extraction pipe 6 extends out of the negative pressure hole sealer 4, and the extraction pipe 6 is connected with a negative pressure branch pipe 7, and each negative pressure branch pipe 7 is connected with a negative pressure main pipe 8 connection; the negative pressure main pipe 8 is connected with a negative pressure pump 9; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com