Continuous movement type food extractor

An extraction device, mobile technology, applied in the field of continuous mobile food extraction device, can solve the problems of low food extraction efficiency and troublesome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

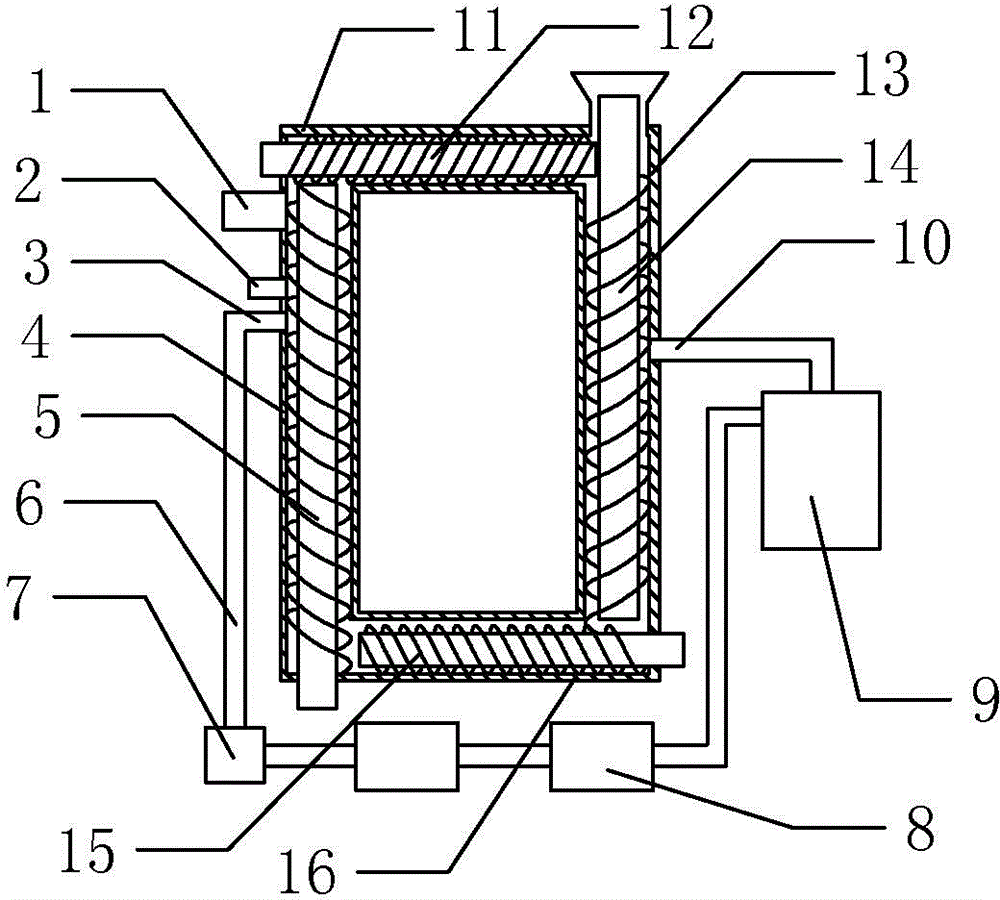

[0012] Among them: slag outlet 1, first liquid inlet pipe 2, second liquid inlet pipe 3, left leaching tower 4, left screw conveyor 5, circulation pipe 6, liquid pump 7, condenser 8, evaporator 9, Outlet pipe 10, upper connecting pipe 11, upper screw conveyor 12, right leaching tower 13, right screw conveyor 14, lower screw conveyor 15, lower connecting pipe 16.

[0013] Such as figure 1 As shown, the continuous mobile food extraction device of the present invention comprises a left extraction tower 4 and a right extraction tower 13, the left extraction tower 4 and the right extraction tower 13 are all placed vertically, the left extraction tower 4 and the right extraction tower An upper connecting pipe 11 and a lower connecting pipe 16 are arranged between the lifting towers 13, and the two ends of the upper connecting pipe 11 are respectively connected with the top of the left leaching tower 4 and the top of the right leaching tower 13, and the two ends of the lower connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com