A preheating device for non-ferrous metal smelting

A preheating device, non-ferrous metal technology, applied in the field of non-ferrous metal smelting, can solve the problems of increasing production input, consuming large energy, increasing energy consumption, emissions and pollution, etc., to reduce combustion heating time, realize recycling, and reduce energy. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The implementation of the invention will be described by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the invention from the content disclosed in this specification.

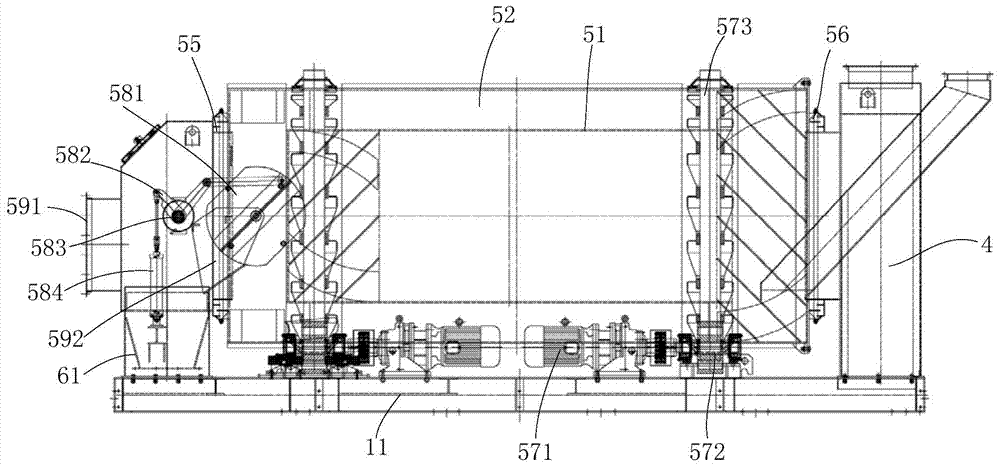

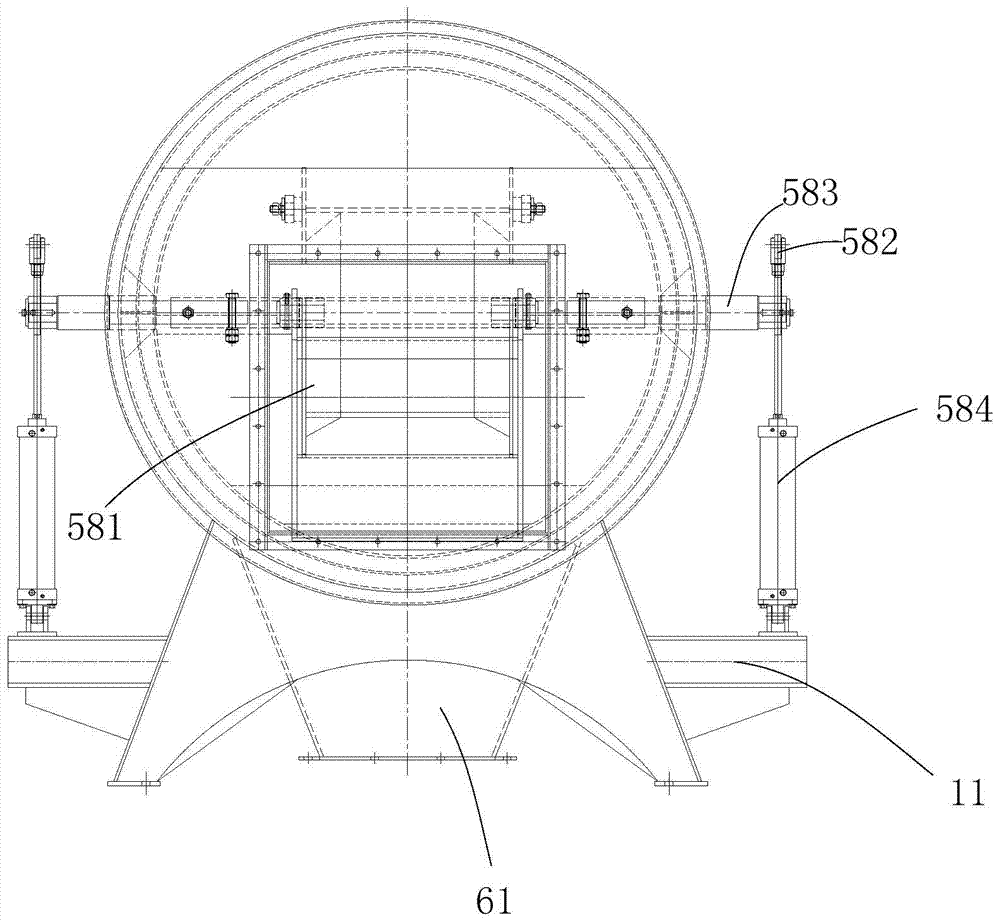

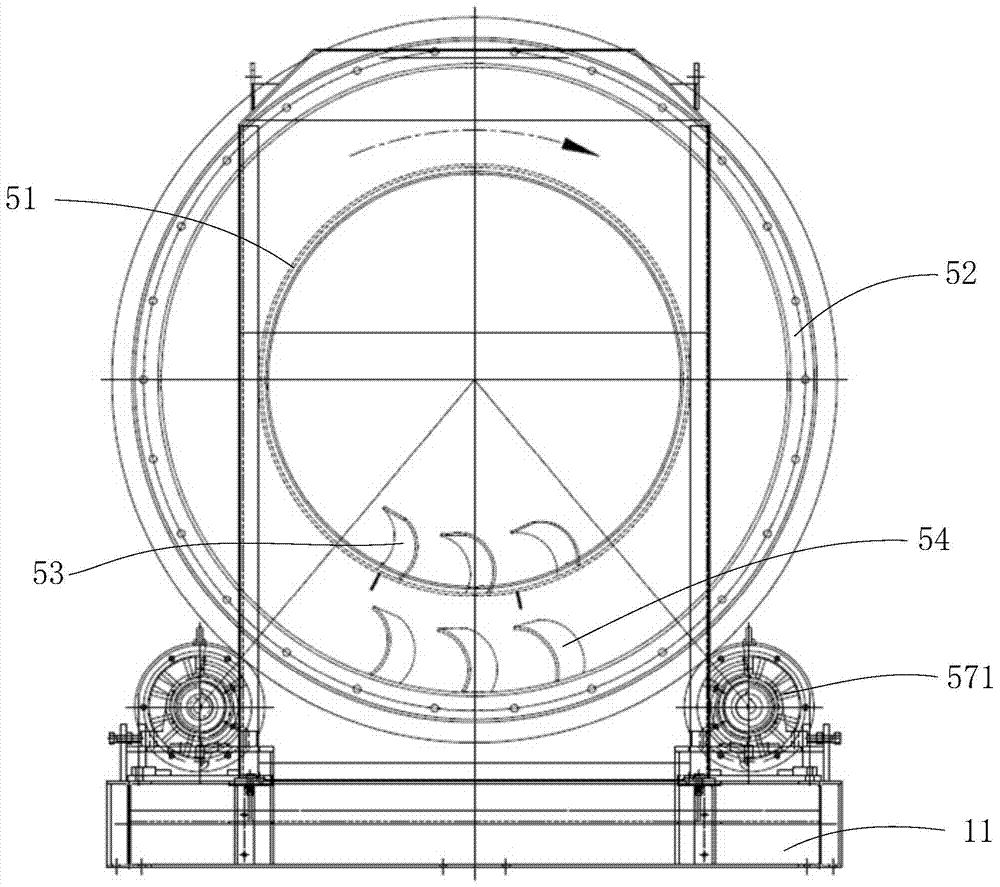

[0050] Such as Figure 1 to Figure 3As shown, the present invention provides a preheating device for non-ferrous metal smelting, including at least one drum and a driving mechanism for driving the rotation of the drum. The driving mechanism is four motors 571 installed on the support base 11, and the motor 571 is connected with a tug wheel 572 , the tugboat 572 cooperates with the flat belt 573 provided on the outer wall of the drum to drive the drum to rotate, the first end of the drum is provided with a feed port and a smoke exhaust port, and the second end of the drum is provided with a waste heat air inlet 591 and a discharge port 592, A plurality of scrapers are arranged obliquely on the inner wall of the drum. When the driving d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com