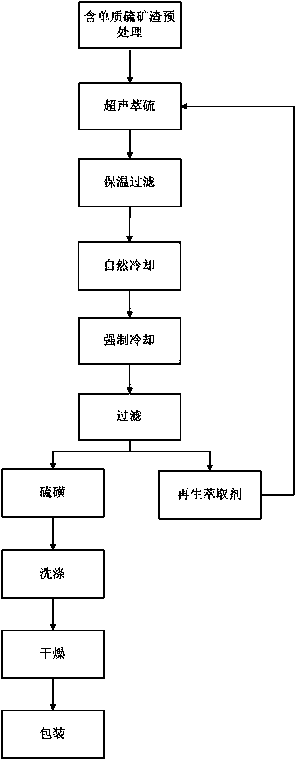

Ultrasonic extraction method and process for processing slag containing elemental sulfur

A technology for elemental sulfur extraction, which is applied in the field of ultrasonic extraction and treatment of elemental sulfur-containing slag, can solve the problems of high energy consumption in thermal filtration, high sulfur content in filter residue, and complicated equipment, and achieve comprehensive economic benefits Significant, large amount of raw material processing, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0030] Composition of sulfur slag (processed through 100 mesh sieve, dry basis): lead 1.22%, zinc 4.75%, indium 0.0029%, silver 0.0569%, sulfur 74.83%. Weigh 5.0000g of sulfur residue, 62.5ml (100g) of a mixture of tetrachlorethylene and toluene, heat in a water bath at 100°C for 30min, and filter immediately to obtain 3.2126g of residue, cool down to 27.5°C to obtain 0.7483g of sulfur, and the extraction rate of sulfur is 32%.

[0031] If ultrasonic extraction is used during the heating reaction, the ultrasonic frequency is 20KHz, and the sound intensity is 2.0-50w / cm 2 Between, the reaction time is 8min, at this moment the extraction rate of sulfur sees the following table:

[0032] Sound intensity (w / cm 2 ) 2.0 2.8 10 20 35 50 output quality 1.3843 1.5714 1.8410 2.1326 2.5442 2.6938 Sulfur extraction rate 37% 42% 49% 57% 68% 72%

[0033] If ultrasonic extraction is used during the heating reaction, the ultrasonic frequency is 100...

Embodiment approach 2

[0038]Composition of sulfur slag (processed through 100 mesh sieve, dry basis): lead 1.22%, zinc 4.75%, indium 0.0029%, silver 0.0569%, sulfur 74.83%. Weigh 10.0000g of sulfur residue, 125ml (100g) of a mixture of trichlorethylene and xylene, heat in a water bath at 100°C for 30min, filter immediately to obtain 6.3962g of residue, cool down to 27.5°C to obtain 2.2449g of sulfur, and the extraction rate of sulfur is 30%. In the comprehensive utilization process of zinc concentrate or lead-zinc mixed ore normal pressure / high pressure oxygen-enriched direct leaching residue, the zinc, lead, and silver in the filter residue are enriched and directly returned to the lead system to recover lead, silver, lead, silver, and indium , Zinc recovery rates were 110%, 34%, 89%, 113%.

[0039] If ultrasonic extraction is used during the heating reaction, the ultrasonic frequency is 30KHz, and the sound intensity is 2.0-50w / cm 2 Between, the reaction time is 9min, at this moment the extract...

Embodiment approach 3

[0046] Composition of sulfur slag (processed through 100 mesh sieve, dry basis): lead 1.22%, zinc 4.75%, indium 0.0029%, silver 0.0569%, sulfur 74.83%. Weigh 10.0000g of sulfur residue, 125ml (100g) of tetrachlorethylene, heat in a water bath at 100°C for 30min, filter immediately to obtain 6.3962g of residue, cool down to 27.5°C to obtain 2.0952g of sulfur, and the sulfur extraction rate is 28%. In the comprehensive utilization process of zinc concentrate or lead-zinc mixed ore normal pressure / high pressure oxygen-enriched direct leaching residue, the zinc, lead, and silver in the filter residue are enriched, and the zinc is first leached and recovered, and then the filter residue is sent to the lead system to recover lead and silver. , the zinc-containing filtrate is returned to the direct leaching system. At this time, the recovery rates of lead, silver, indium, and zinc were 120%, 36%, 85%, and 124%, respectively.

[0047] If ultrasonic extraction is used during the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com