Novel degreasing process of egg yolk powder

A technology of egg yolk powder and egg oil, applied in the direction of fat production, fat oil/fat production, fat oil/fat refining, etc., can solve the problems of low extraction pressure, low extraction efficiency, high extraction pressure, etc., and achieve stable operation process and high extraction efficiency High, high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

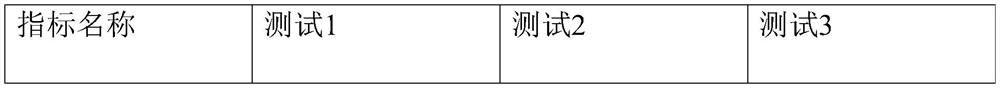

Image

Examples

Embodiment 1

[0028] 1) granulation: add 95% food-grade ethanol of 15% powder weight to the egg yolk powder qualified in quality inspection, cross a 5mm aperture sieve to make cylindrical egg yolk powder particles with a particle diameter of 5mm;

[0029] 2) Drying: Dry the granulated cylindrical egg yolk powder granules at 45°C under dry heat conditions for 50 minutes, and the granules are required to still contain no less than 2% ethanol by weight of the granules as an entrainer during supercritical extraction;

[0030] 3) Filling: Fill the barrel with the dried cylindrical egg yolk powder particles and put them into a 1L extraction kettle;

[0031] 4) Extraction: main parameters of extraction: extraction pressure 27Mpa, temperature 38°C; flow rate 50L / h, extraction time 90min;

[0032] 5) Separation: the extracted mixed material passes through the separation tank, where the egg oil settles and separates at the bottom of the separation tank, the separation pressure is 4MPa, and the temper...

Embodiment 2

[0038] 1) granulation: add 95% food-grade ethanol of 15% powder weight to the egg yolk powder qualified in quality inspection, cross a 5mm aperture sieve to make cylindrical egg yolk powder particles with a particle diameter of 5mm;

[0039] 2) Drying: Dry the granulated cylindrical egg yolk powder granules at 45°C under dry heat conditions for 50 minutes, and the granules are required to still contain no less than 2% ethanol by weight of the granules as an entrainer during supercritical extraction;

[0040] 3) Filling: Fill the barrel with the dried cylindrical egg yolk powder particles and put them into a 1L extraction kettle;

[0041] 4) Extraction: main parameters of extraction: extraction pressure 25Mpa, temperature 35°C; flow rate 45L / h, extraction time 100min;

[0042] 5) Separation: the extracted mixed material passes through the separation tank, where the egg oil settles and separates at the bottom of the separation tank, the separation pressure is 4MPa, and the tempe...

Embodiment 3

[0048] 1) granulation: add 95% food-grade ethanol of 15% powder weight to the egg yolk powder qualified in quality inspection, cross a 5mm aperture sieve to make cylindrical egg yolk powder particles with a particle diameter of 5mm;

[0049] 2) Drying: Dry the granulated cylindrical egg yolk powder granules at 45°C under dry heat conditions for 50 minutes, and the granules are required to still contain no less than 2% ethanol by weight of the granules as an entrainer during supercritical extraction;

[0050] 3) Filling: Fill the barrel with the dried cylindrical egg yolk powder particles and put them into a 1L extraction kettle;

[0051] 4) Extraction: main parameters of extraction: extraction pressure 25Mpa, temperature 40°C; flow rate 50L / h, extraction time 90min;

[0052] 5) Separation: the extracted mixed material passes through the separation tank, where the egg oil settles and separates at the bottom of the separation tank, the separation pressure is 4MPa, and the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com