Viscous organic solid waste uniform distribution type feeding pyrolysis system

An organic solid waste, uniformly distributed technology, used in pyrolysis treatment of sludge, special forms of dry distillation, petroleum industry, etc., can solve problems such as poor pyrolysis stability and uneven feeding, and achieve good sealing performance and enhanced sealing. effect, the effect of reducing the difficulty of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0028] Aiming at the existing problems, the present invention provides a uniformly distributed feeding pyrolysis system for viscous organic solid waste. efficiency.

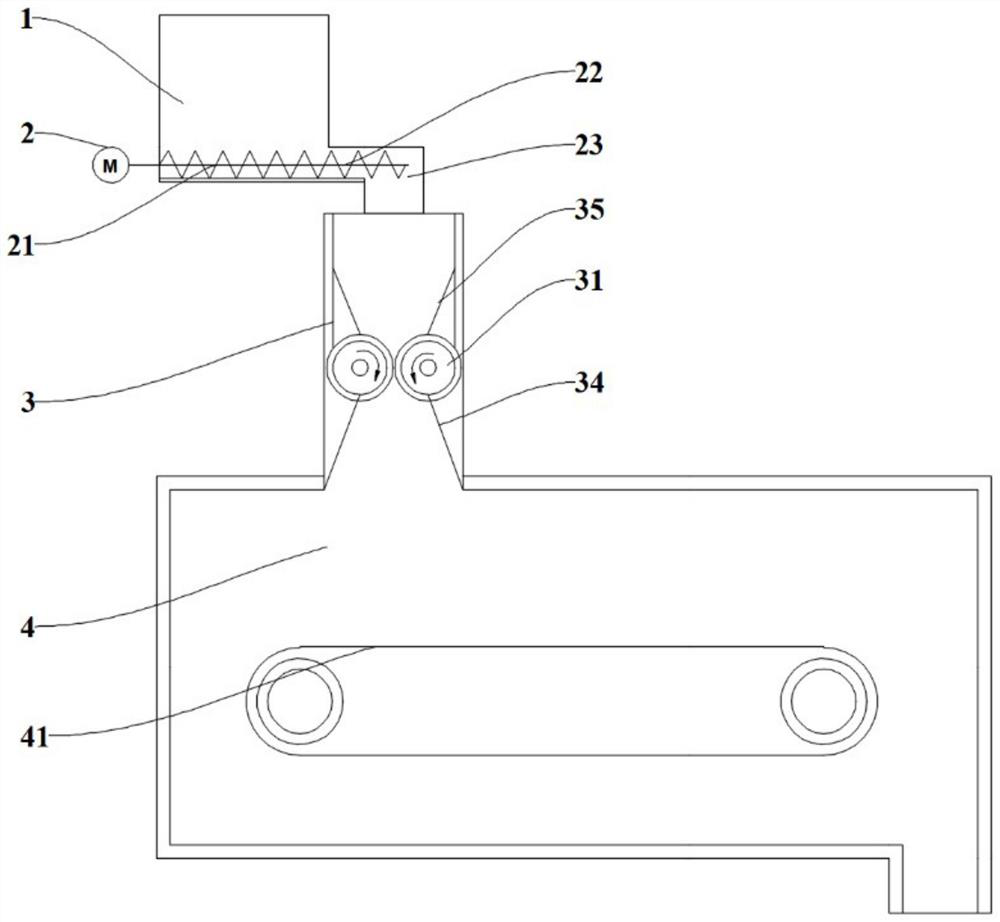

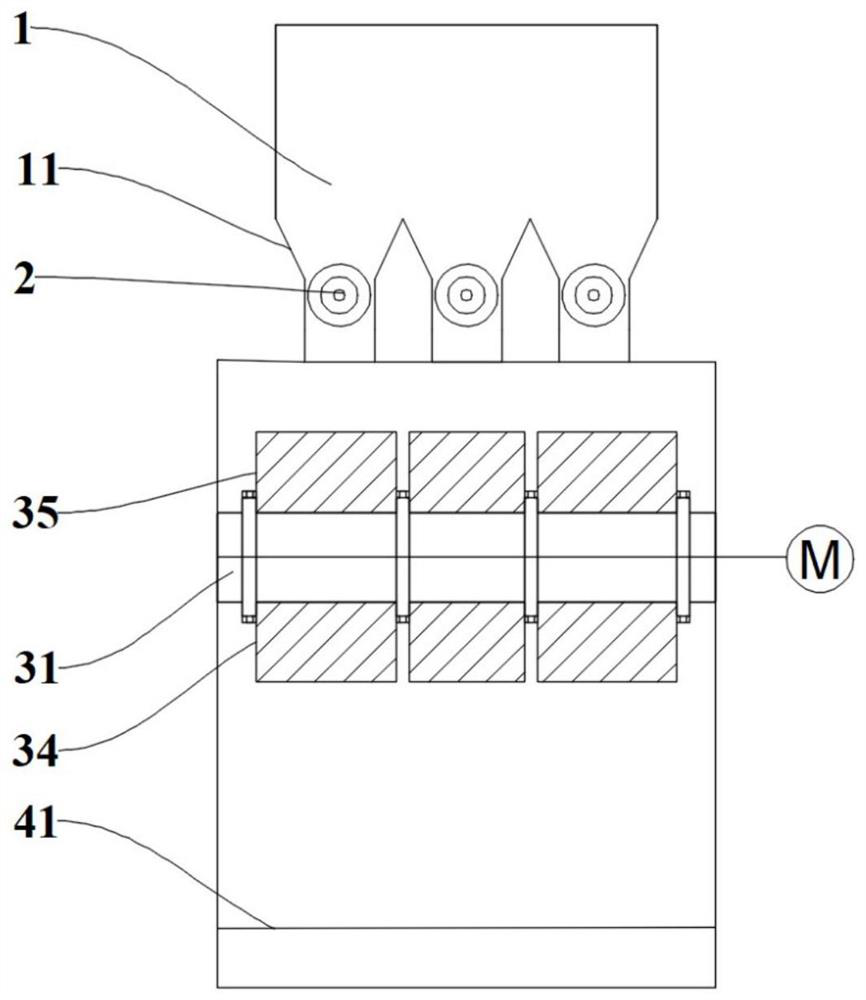

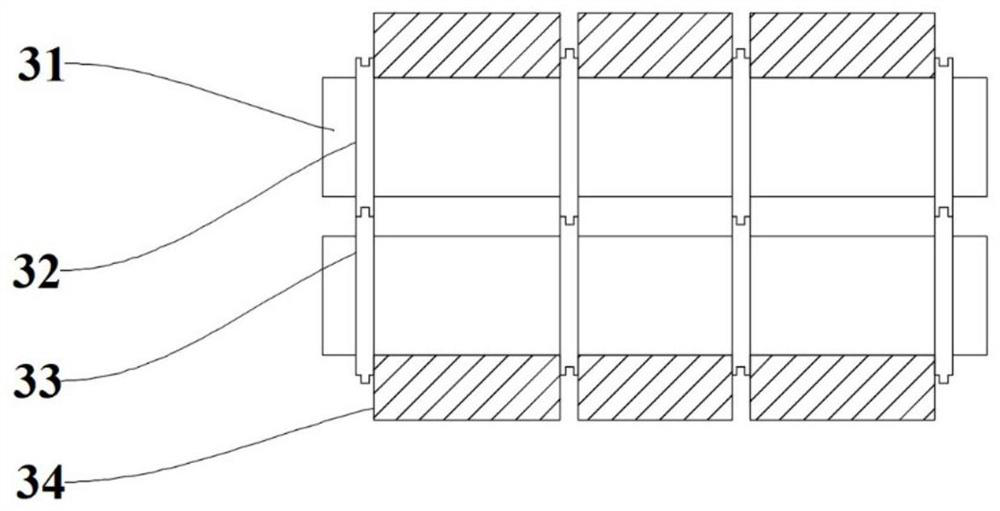

[0029] In order to realize the above technical solutions, such as Figure 1-4 As shown, the embodiment of the present invention provides a uniformly distributed feeding pyrolysis system for viscous organic solid waste, including a silo 1, a screw feeder 2, a pair of roller extrusion feeding devices 3, and a chain plate thermal Solution device 4; Wherein:

[0030] The silo is used to store materials, and the bottom of the silo is equipped with a sloping plate 11 to form a tapered outlet to facilitate the falling of the material; three screw feeders 2 are horizontally arranged below the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com