A kind of preparation method and application of nano crystal seed for auxiliary gelling material system

A technology of auxiliary cementitious materials and nano-crystal seeds, which is applied in the field of concrete admixtures, can solve the problems of reducing concrete compactness, long cement setting time, and increased seed crystal size, so as to reduce water evaporation rate and capillary pressure , the effect of reducing the saturated vapor pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

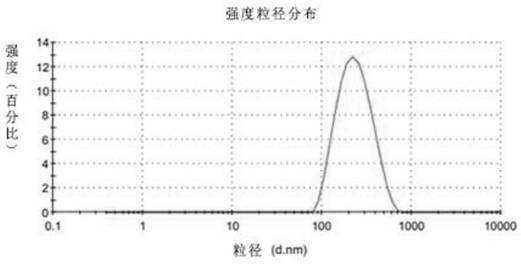

[0047] A preparation method for nano-crystal seeds used in high-doped auxiliary gelling material system, 30 parts of dispersant, 1 part of DF-999 polyether defoamer, 99 parts of diethylene glycol monobutyl ether, triisopropanol 7 parts of amine, 8 parts of diethanolamine, 10 parts of lithium magnesium silicate, 10 parts of magnesium aluminum silicate and 570 parts of water, heat and control the temperature at 30 ° C, stir evenly at a speed of 200 rpm, and drop at a constant rate Add 160 parts of 36wt% calcium hydroxide solution and 125 parts of 28wt% sodium silicate solution, the dropping time of calcium hydroxide solution is 12h, the dropping time of sodium silicate solution is 9h, after dropping starts, the rotating speed is raised to 1000rpm, keep the rotation speed until the dropwise addition is completed, then cool to below 5°C within 2 minutes, and age for 2 hours to obtain nano-crystal seeds;

[0048] Wherein the dispersant includes the following components by mass perc...

Embodiment 2

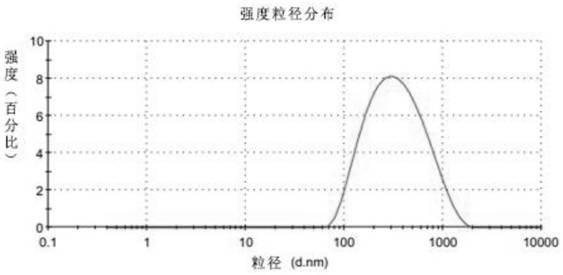

[0050] A kind of preparation method of the nano-crystal seed that is used in the system of high-doped auxiliary gelling material, 40 parts of dispersant, 10 parts of DF-999 polyether defoamer, 90 parts of diethylene glycol monobutyl ether, triisopropanol 7 parts of amine, 8 parts of diethanolamine, 30 parts of magnesium aluminum silicate thickener and 570 parts of water, heat and control the temperature at 30 ° C, stir evenly at a speed of 200 rpm, and drop 40 wt% of 160 parts of calcium hydroxide solution and 125 parts of 30wt% sodium silicate solution, the dropwise addition time of calcium hydroxide solution is 12h, the dropwise addition time of sodium silicate solution is 9h, after the dropwise addition starts, the rotating speed is raised to 1000rpm, and the rotating speed remains After the dropwise addition is completed, cool down to below 5°C within 2 minutes, and age for 2 hours to obtain nano-crystal seeds;

[0051] Wherein the dispersing agent comprises the following ...

Embodiment 3

[0053] The difference from Example 1 is that the alcohol ether is 40 parts of diethylene glycol monobutyl ether and 60 parts of polyoxytetramethylene glycol with a molecular weight of 2000 Da, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com