Back cloth for fluffing card clothing

A back cloth, red technology, applied in the direction of film/sheet adhesive, non-polymer adhesive additive, adhesive type, etc., can solve the problems of low back friction, degumming, slippage, etc. Good effect of slipping and combing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] Embodiment 1, a kind of back cloth for raising clothing is characterized in that: it is composed of a base, a rubber adhesive surface and a red surface, the rubber adhesive surface is above the base, and the red surface is below the base; the base is made up of cotton cloth; The rubber adhesive surface is made by coating and drying the adhesive; the red surface is made by coating and drying water-based polyurethane paint.

[0014] The base cotton cloth adopts: cotton yarn: warp combed yarn, weft combed yarn; cotton yarn count: warp 16S, weft 21S; cotton density: warp density 105 / inch, weft density 56 / inch; cotton thickness 0.39~0.42mm, warp breaking strength 1300N, breaking elongation 9%.

[0015] The adhesive used on the surface of the rubber adhesive is made from mixing rubber A and gasoline in a mass ratio of 1:3.5;

[0016] The mixed rubber A is made by mixing the following raw materials by mass: 100 parts of Thailand No. 3 natural rubber, 1.5 parts of sulfur, 1....

Example Embodiment

[0019] Embodiment 2, a kind of back cloth for raising clothing is characterized in that: it is composed of a base, a rubber adhesive face and a red face, the rubber adhesive face is above the base, and the red face is below the base; the base is made up of cotton cloth; The rubber adhesive surface is made by coating and drying the adhesive; the red surface is made by coating and drying water-based polyurethane paint.

[0020] The base cotton cloth is the same as that of Example 1.

[0021] The adhesive used on the surface of the rubber adhesive is the same as in Example 1.

[0022] The red surface-use polyurethane paint is applied, and the paint is made of water-based polyurethane emulsion EPW-T99S and thickener 2681 mixed with color paste, and then adds 5% of water-based polyurethane with a bright red paste, wherein the water-based polyurethane emulsion and The mixing ratio of color paste is 1:2.

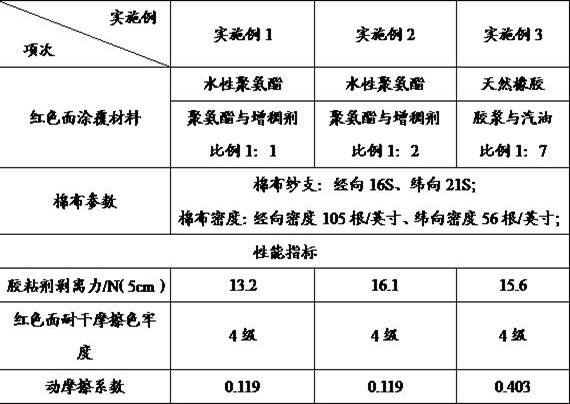

[0023] The performance indicators are shown in Table (1).

Example Embodiment

[0024] Embodiment 3, a kind of back cloth for raising clothing is characterized in that: it is composed of a base, a rubber adhesive surface and a red surface, the rubber adhesive surface is above the base, and the red surface is below the base; the base is made up of cotton cloth; The rubber adhesive surface is made by coating and drying the adhesive; the red surface is made by coating and drying natural rubber paint.

[0025] The base cotton cloth is the same as that of Example 1.

[0026] The adhesive used on the surface of the rubber adhesive is the same as in Example 1.

[0027] When the red surface is coated with natural rubber glue, the glue used is made by mixing rubber B and gasoline in a mass ratio of 1:7.

[0028] The mixed rubber B is made from the following raw materials by mass: 100 parts of natural rubber, 1.4 parts of sulfur, 1.5 parts of 2,2'-dithiodibenzothiazole, and 1.3 parts of 2-mercaptobenzothiazole , 5 parts of zinc oxide, 1 part of stearic acid, 130 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Longitudinal breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com