Transmission, power assembly and power equipment

A technology of transmission and synchronizer, which is applied in the field of vehicle engineering and can solve the problems of increased number of gear pairs, unfavorable placement, and large center distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

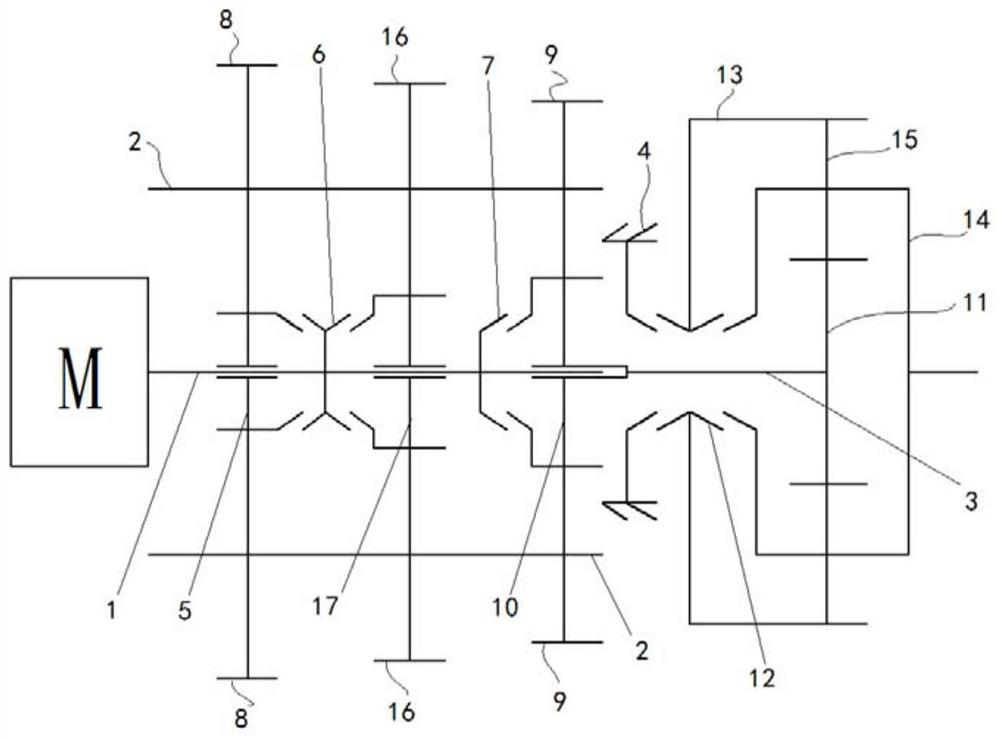

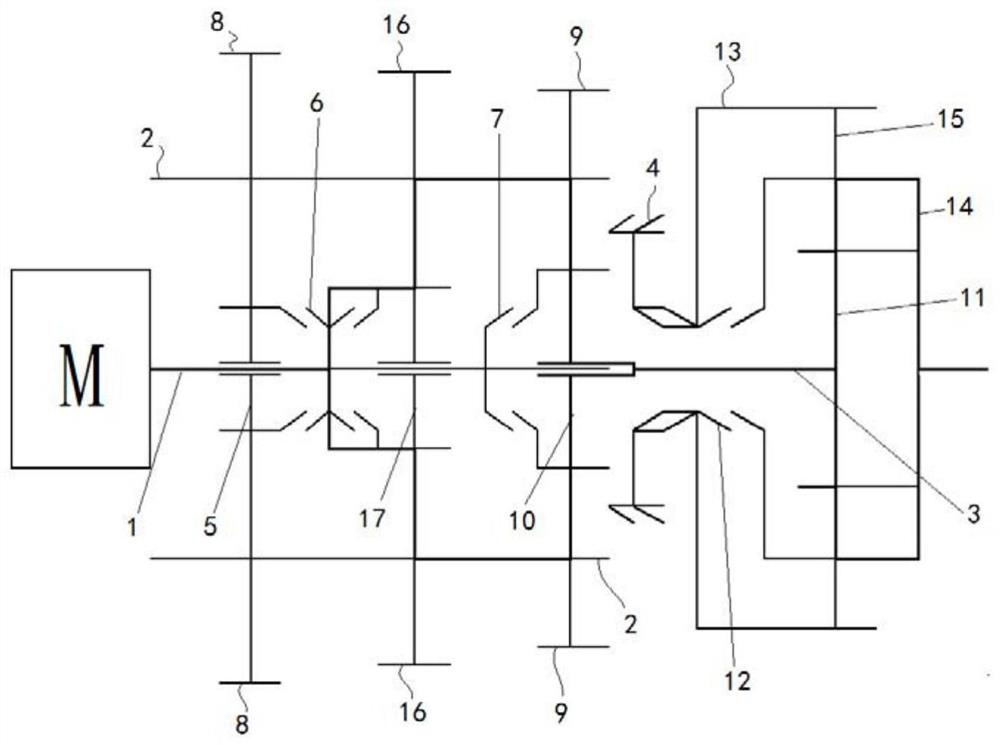

[0044] Such as Figure 1 to Figure 7 As shown, a transmission provided in this embodiment includes: a housing 4; an input shaft system, the input shaft system includes: an input shaft 1; at least one first main transmission member 5, which is spaced apart from the input shaft along the axial direction. On the shaft 1; at least one first synchronizer 6 is arranged on the input shaft 1 adjacent to the first main transmission member 5, and the first synchronizer 6 is combined or separated from the first main transmission member 5; and is arranged on the input shaft 1 The second synchronizer 7; the intermediate shaft system, the intermediate shaft system includes: at least one intermediate shaft 2, arranged in parallel with the input shaft 1; at least one first follower 8, fixed on the intermediate shaft 2, the first driven 8 is matched with the first main transmission member 5; and the second main transmission member 9 fixed on the intermediate shaft 2; the planetary gear train, ...

Embodiment 2

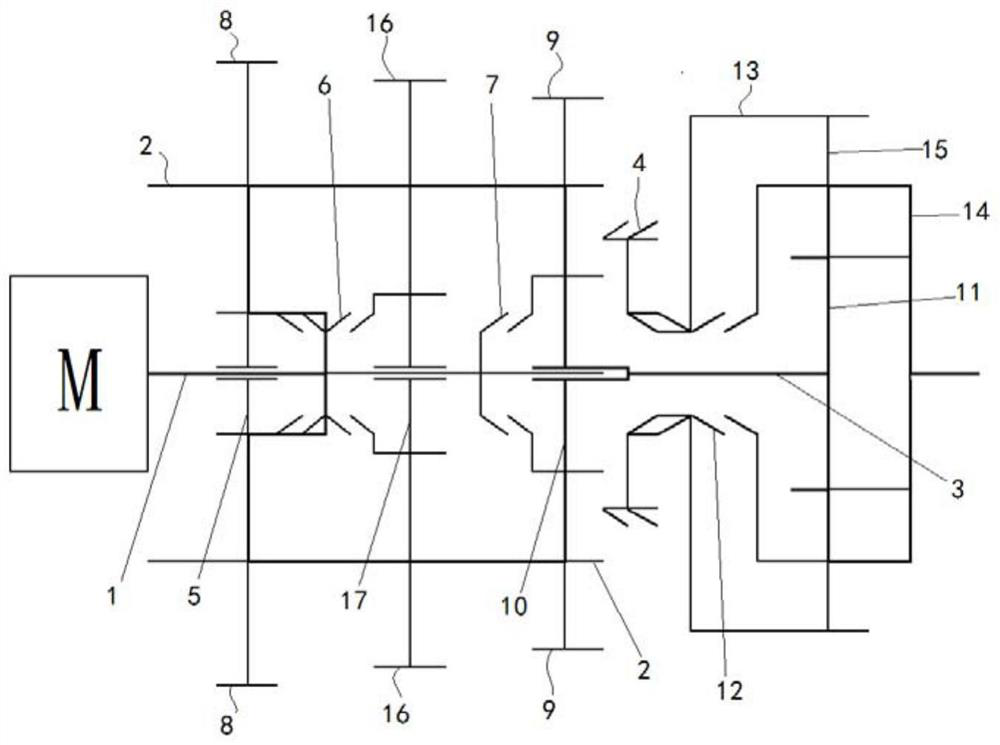

[0068] This embodiment provides a transmission, including: a housing 4; an input shaft system, the input shaft system includes: an input shaft 1; at least one first main transmission member 5, fixed on the input shaft 1 at intervals along the axial direction; And the second synchronizer 7 arranged on the input shaft 1; the intermediate shaft system, the intermediate shaft system includes: at least one intermediate shaft 2, arranged in parallel with the input shaft 1; at least one first follower 8, spaced and sleeved in the middle On the shaft 2, the first driven member 8 cooperates with the first main transmission member 5; at least one first synchronizer 6 is arranged on the intermediate shaft 2 adjacent to the first driven member 8, and the first synchronizer 6 and the first The driven member 8 is combined or separated; and the second main transmission member 9 fixed on the intermediate shaft 2; the planetary gear train, the planetary gear train includes: the output shaft 3, ...

Embodiment 3

[0071] This embodiment provides a power assembly, including: a motor; and the transmission of any one of the above-mentioned embodiment 1 or embodiment 2, the output end of the motor is connected to the input shaft 1, and has all its technical advantages, No more details here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com