Air source heat pump

An air-source heat pump and accommodating space technology, applied in the field of heat pumps, can solve the problems of insufficient stability of the product center of gravity, low adaptability to complex water quality, high post-maintenance costs, etc., to protect the stability of the structure, reduce the impact of stress, and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

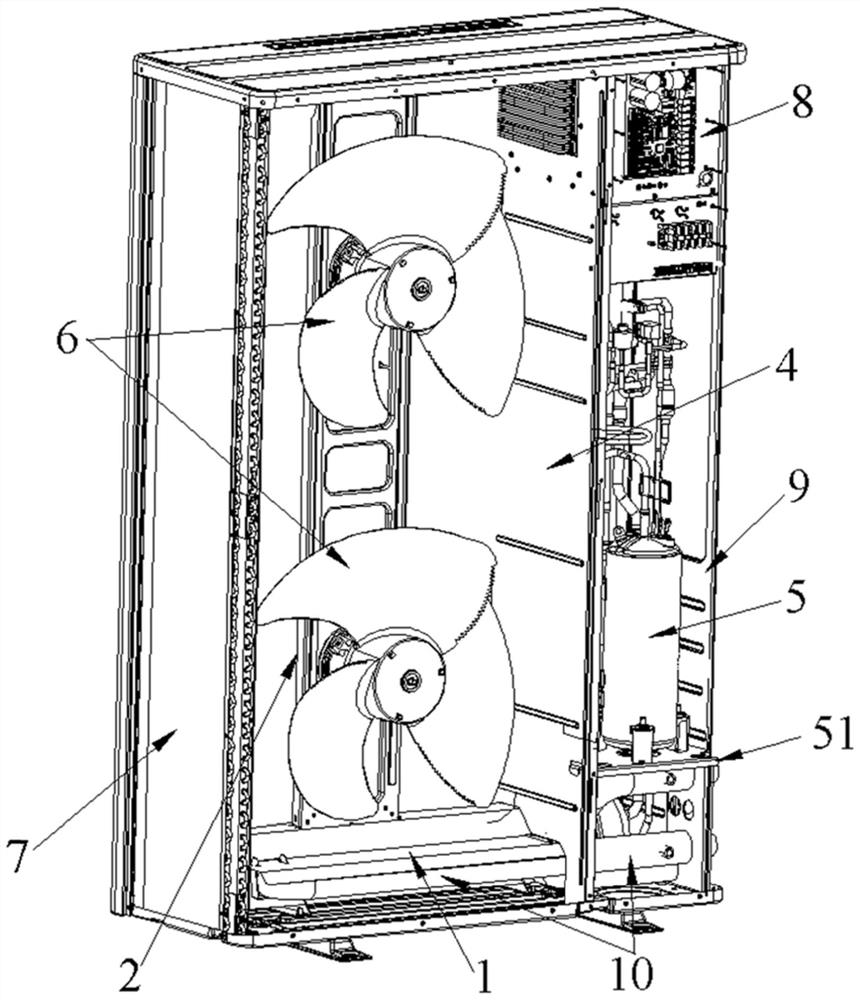

[0058] In this example, if figure 1 As shown, an air source heat pump is provided, including:

[0059] The shell 9 is provided with a middle partition 4 that separates the internal accommodation space;

[0060] The fan 6 is arranged on the fan frame 2 on one side of the middle partition 4;

[0061] The evaporator 7 is arranged along the side wall and the rear wall of the casing 9, and is on the same side of the middle partition 4 as the fan 6;

[0062] The compressor 5 and the electric control element 8 are located on the other side of the middle partition 4 opposite to the fan 6;

[0063] The air source heat pump also includes a condenser 10 covering the inner bottom of the housing 9 and passing through the middle partition 4 . The condenser 10 is provided with a guard plate 1 against the middle partition 4 .

[0064] In this embodiment, the condenser (water side) in the heat pump is arranged at the bottom of the body, which can lower the center of gravity of the whole mac...

Embodiment 2

[0074] The difference between this embodiment and embodiment 1 is:

[0075] In this embodiment, the fan frame 2 is assembled on the top of the condenser 10 .

[0076] In this embodiment, since the condenser 10 occupies the bottom space of the machine body, the fan rack cannot be used in the prior art, that is, the fan rack is directly connected to the chassis of the machine body. In view of this, in this embodiment, the fan bracket 2 is installed on the condenser 10 in view of space utilization and installation fastness. Specifically, screw holes can be provided on the side of the bottom of the fan frame 2 to correspond to the screw holes of the vertical plates on the upper surface of the condenser 10 .

[0077] Other implementation modes of this embodiment are the same as embodiment 1.

Embodiment 3

[0079] This embodiment is a further improvement to the air source heat pump on the basis of Embodiment 1, specifically including:

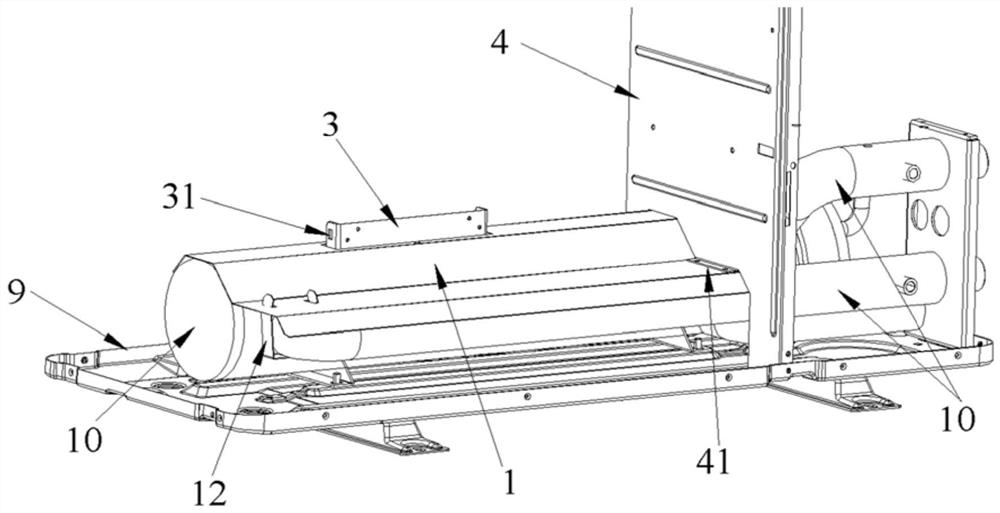

[0080] In this example, if figure 2 As shown, the heat pump also includes a support 3 assembled with the bottom of the fan frame 2 , and the support 3 is installed on the top of the guard plate 1 .

[0081]In this embodiment, when a plurality of fans 6 are installed on the fan frame 2, or the height of the shell of the machine body is high, a support structure can be added on the guard plate 1 to increase the bearing capacity of the fan frame. The support 3 can not only increase the installation fastness of the fan frame 2, but also reduce the influence of the stress generated when the fan 6 is working, thereby prolonging the service life of the guard plate 1.

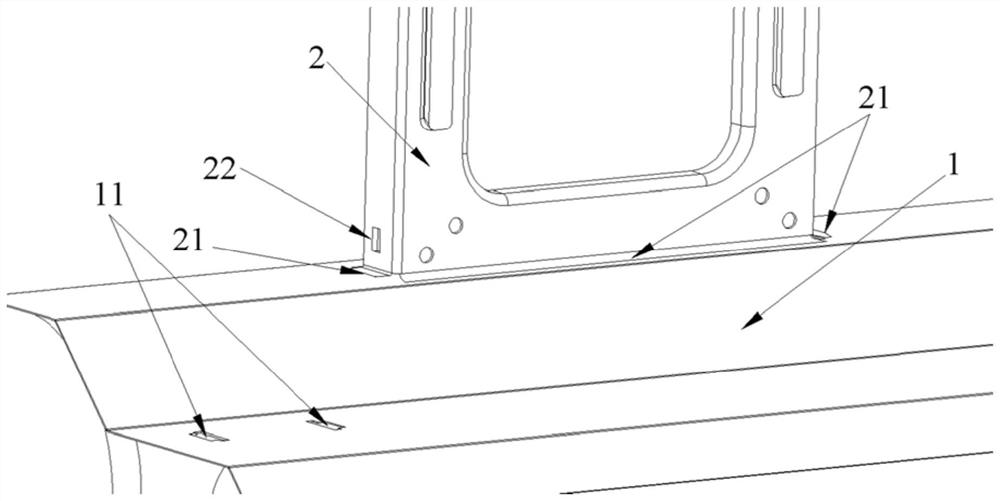

[0082] In this example, if Figure 4 As shown, at least two opposite sides of the support 3 are provided with bayonets 31, and the bottom of the fan frame 2 is provided with claws 22 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com