Annular sponge wetland garden and construction method thereof

A sponge and wetland technology, which is applied to the annular sponge wetland garden and its construction field, can solve the problems of increasing the construction cost of sponge facilities, large area, difficult construction, etc., and achieves improved rainwater treatment efficiency, small area and convenient construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

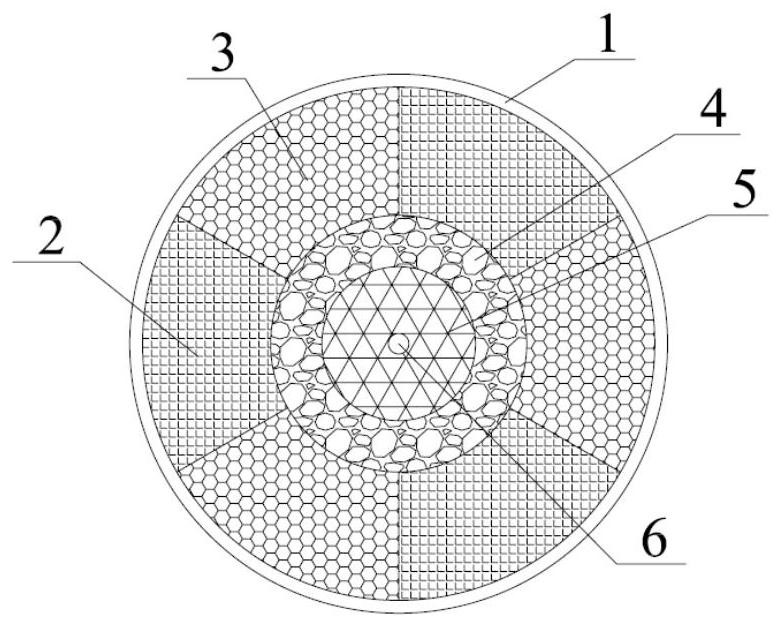

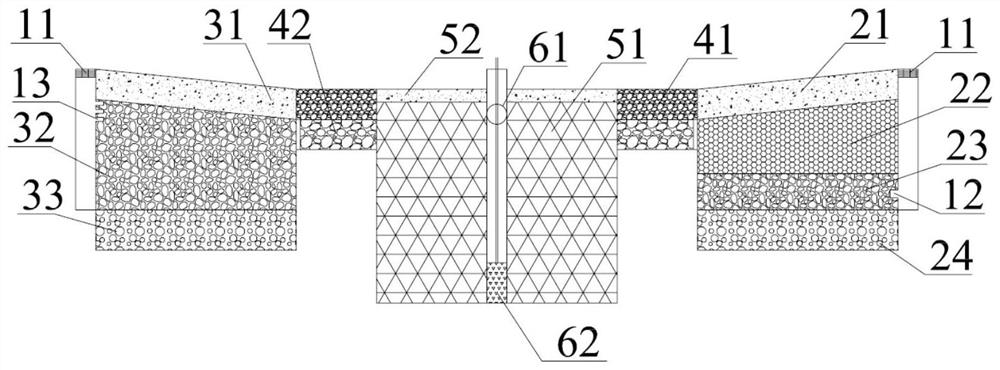

[0055] Such as figure 1 As shown, the present application adopts a ring-shaped sponge wetland garden. The surface of the ring-shaped sponge wetland garden is a circular structure, and rainwater enters the catchment channel 1 along the entire circumference at all angles. And from the outside to the inside are the catchment channel 1, the high load area 2 and the low load area 3, the buffer zone 4, the water storage area 5 and the central well 6.

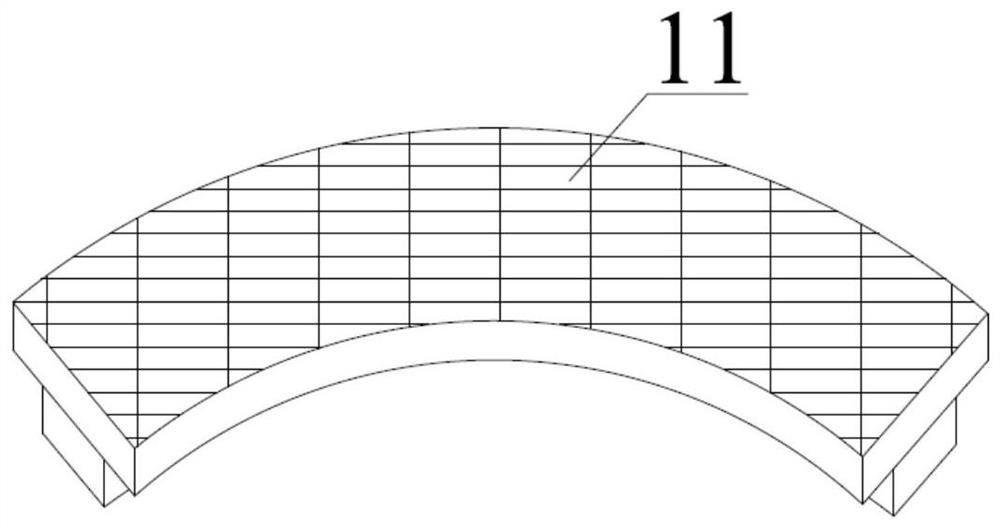

[0056] Drainage channel 1, including the inner cylinder (such as Figure 4 with Figure 5 Shown) and outer cylinder 15 (such as Image 6 As shown), a water collection area is formed between the inner cylinder and the outer cylinder 15; wherein, the inner cylinder is spliced by several sub-tubes, and some of the sub-tubes are provided with an upper water inlet in the upper area Hole 13 (eg Figure 5 shown), the other part of the cylinder is provided with a lower water inlet hole 12 in the lower area (such as Figure 4 shown); th...

Embodiment 2

[0071] A construction method for a ring-shaped sponge wetland garden, following the construction principles of bottom-up, inside-out, first underground and then above-ground, including the following steps:

[0072] Step 1: The foundation pit is excavated from the outside to the inside, excavating in layers according to the design requirements. After the excavation is completed, compact the bottom of the foundation pit separately, and then carry out the construction of the waterproof layer of the overall foundation pit after the degree of compaction reaches more than 95%;

[0073] Step 2: The HDPE film is installed on the slope, and the overall structure should be adopted to avoid hot-melt joints. The inevitable joints should be controlled in the gentle slope area, and the tightness detection of the interface of the film laid in the horizontal position should be strengthened to strictly control the construction Quality, after the HDPE film installation is completed, the next st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com