Trough type solar support based on principle of gravity and mounting method of support

A trough solar energy, principle technology, applied in solar thermal devices, solar thermal energy, solar thermal power generation and other directions, can solve the problems of inconvenient support, inaccurate installation location, time-consuming and labor-intensive, etc., to achieve accurate installation location, reasonable structural design, The effect of the overall structure is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

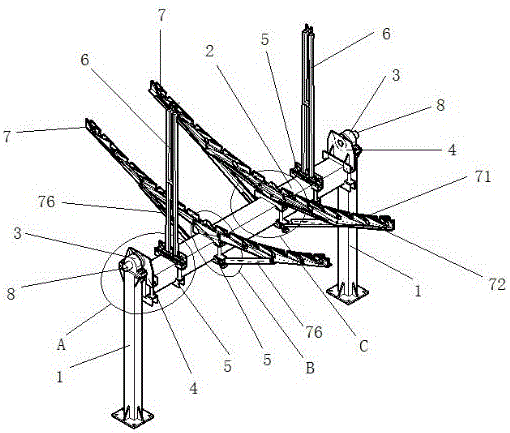

[0053] like Figure 1 to Figure 9 As shown, this embodiment provides a method for installing a trough solar support based on the principle of gravity, including the following steps:

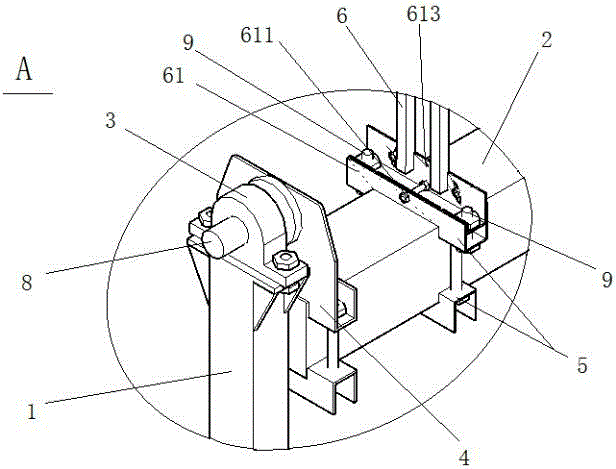

[0054] (1) Install two support rods 1 standing parallel to each other, and install a bearing seat 3 on the upper ends of the two support rods 1;

[0055] (2) Set a torque tube 2 whose length is equal to the distance between the two support rods 1, and install a crank 4 at both ends of the torque tube 2, and connect the bearing housing 3 and the crank 4 through a shaft rod 8 In one piece, the shaft rod 8 is fixedly welded to the crank at the same time, so that the torque tube 2 is erected on the two support rods 1;

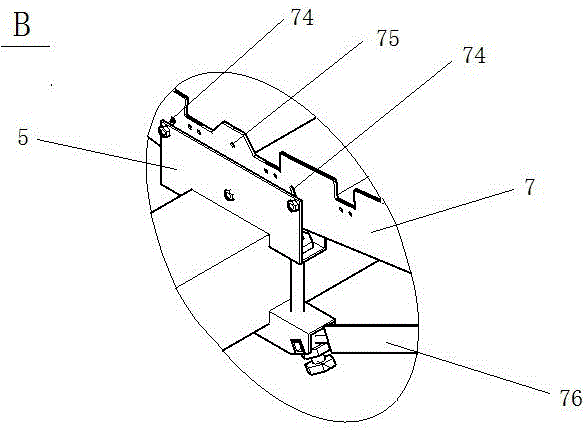

[0056] (3) Install four sets of hoop assemblies 5 on the torque tube 2, and adjust the hoop assemblies 5 to the optimal position, and then lock the four sets of hoop assemblies 5 on the torque tube 2 with screws;

[0057] (4) A vacuum tube bracket 6 is installed on the hoop assembly...

Embodiment 2

[0067] like Figure 10 , Figure 11 As shown, the main difference between this embodiment and Embodiment 1 mainly lies in:

[0068] The step (5) specifically includes the following steps: a first tapered reference hole 613 is opened on the connecting plate 61 and located at the lower end of the first rotation center hole 611 , and a taper hole 613 is opened at the middle position of the other end corresponding to the vacuum tube support 6 . The second tapered reference hole 62 inserts a heavy perpendicular 10 in the first tapered reference hole 613. If the heavy perpendicular 10 coincides with the second tapered reference hole 62, the two first strip holes 612 The screw at the position is locked, and the second telescopic rod 9 is added between the connecting plate 61 and the hoop assembly 5, and the vacuum tube support 6 is further locked on the hoop assembly 5 with the screw, and the heavy vertical line 10 is removed Otherwise, adjust the position of the vacuum tube suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com