Method for realizing mechanical zero position detection adjustment by monochromatic light imaging

A mechanical zero position and monochromatic light technology, which is applied in the field of aerospace, can solve the problems of simple mechanical structure, complicated installation steps, and high precision requirements of parts, and achieve the effect of high zero adjustment accuracy, simple structure, and low installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing:

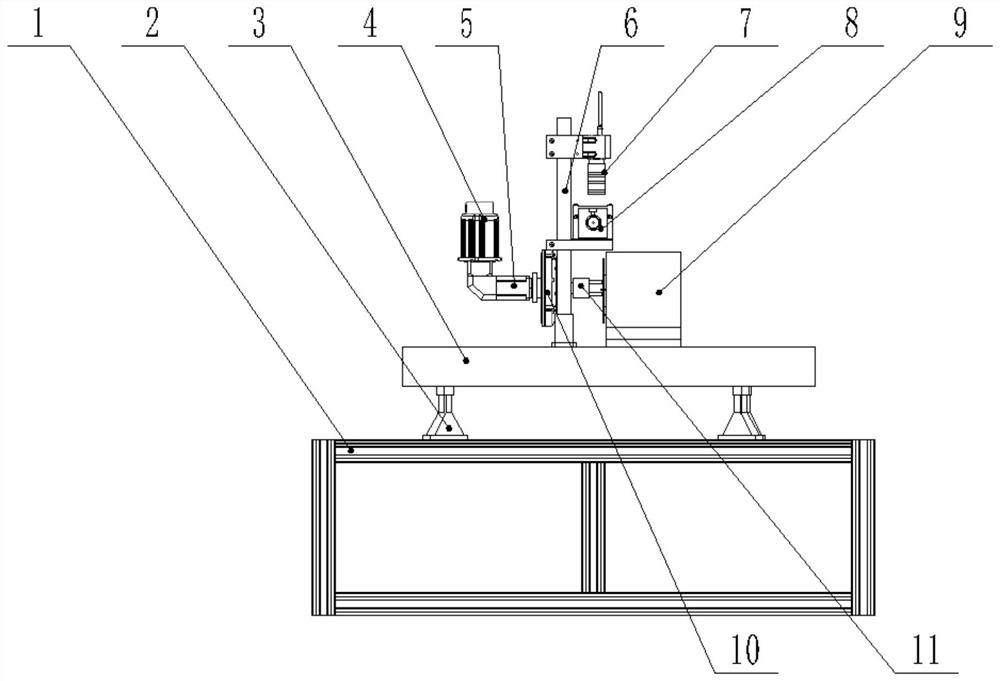

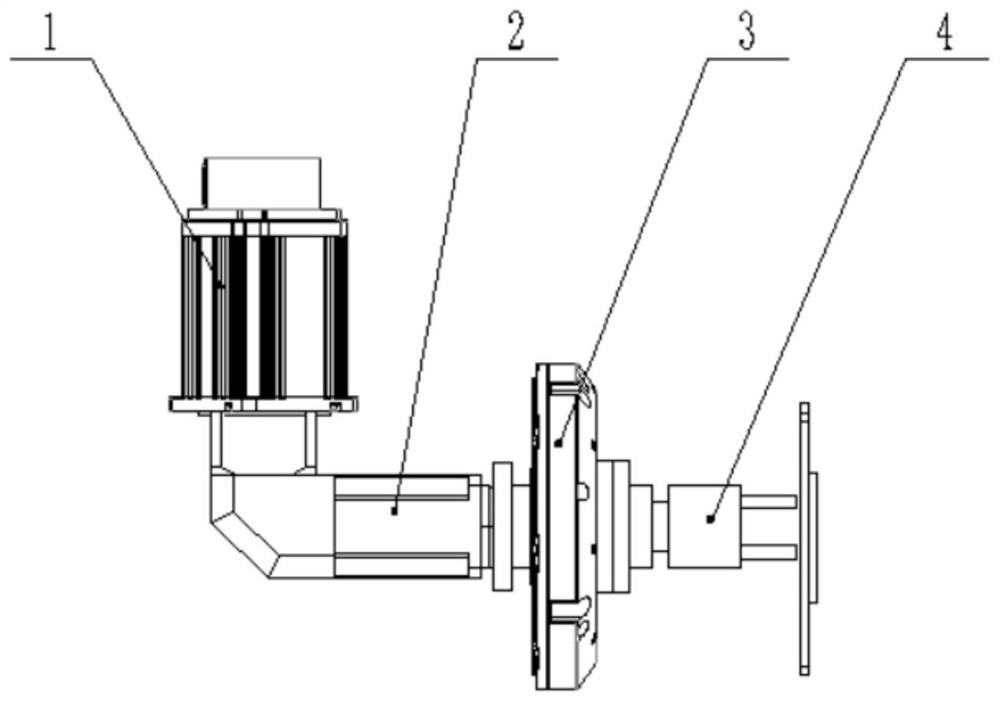

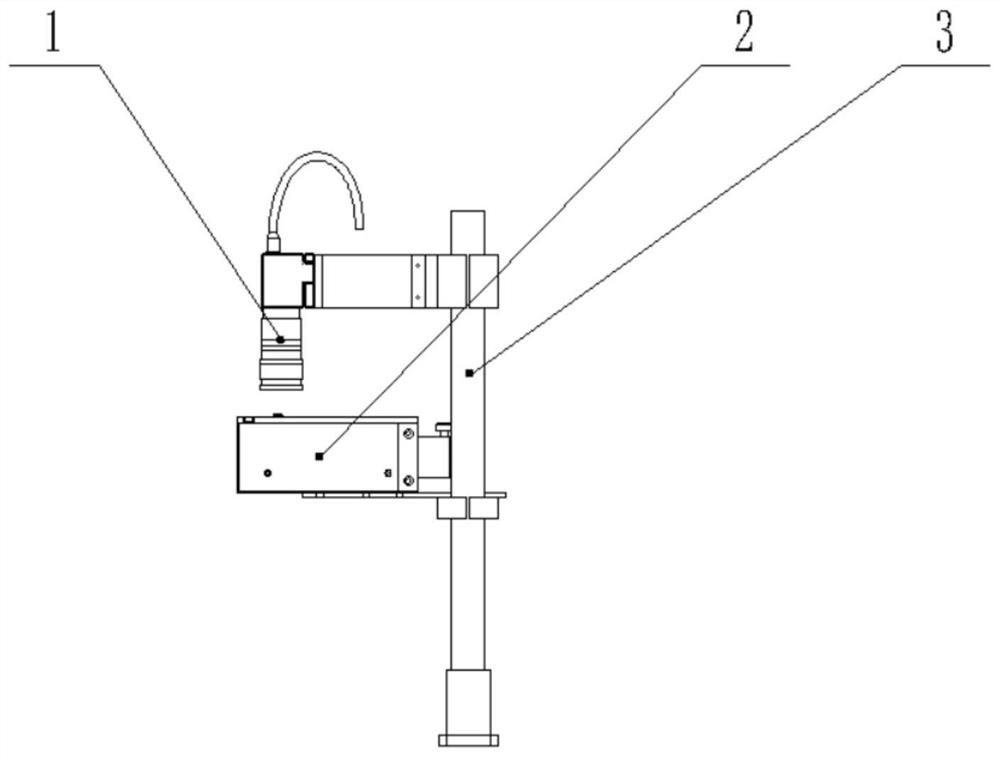

[0037] Such as Figure 1~4 As shown, a method for realizing mechanical zero position detection and adjustment relying on monochromatic light imaging, the device used includes aluminum profile support 1, marble support 2, marble platform 3, servo motor 4, reducer 5, rotating spindle, optical support 6. Industrial camera 7, coaxial parallel light source 8, code disc 10, customized universal joint 10 and tooling to be tested 9, industrial camera 7, coaxial parallel light source 8 and optical bracket 6 constitute the optical mechanism of the entire device, and servo motor 4 , speed reducer 5, rotating main shaft, encoder disk 10 and customized universal joint 10 constitute the driving mechanism of the whole device.

[0038] The surface of the marble platform 3 is pasted with six small white dots for detecting the levelness of the marble platform 3. The six small white dots are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com