A rapid method for determining the dosage and cooling range of a viscosity-reducing road warm mix admixture

A technology for temperature reduction range and determination method, which is applied in the direction of measuring devices, material thermal analysis, instruments, etc., can solve the problems of lack of discrimination, not economical, and difficult to achieve the best dosage effect, so as to save the verification process and save Time-consuming and labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The method for quickly obtaining the optimum dosage of the organic viscosity-reducing temperature-mixing agent and the cooling range of the warm-mix asphalt mixture according to the present invention comprises the following steps:

[0035] (1) Preparation of experimental instruments, prepare 600mL beakers, stirring rods, five sets each, oven, holding furnace and electronic balance (accurate to 0.01g), one set;

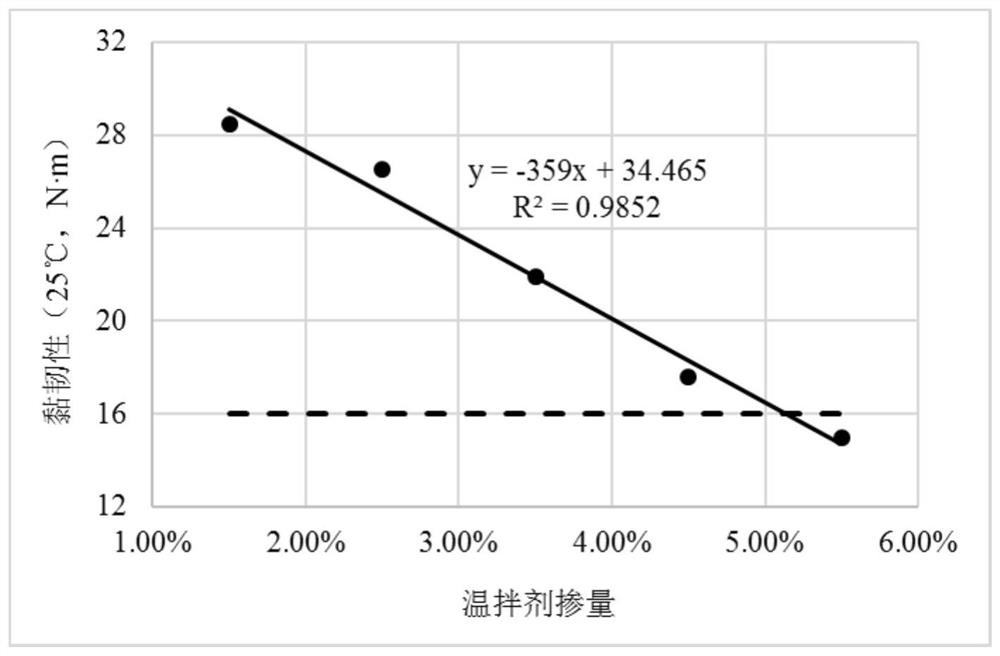

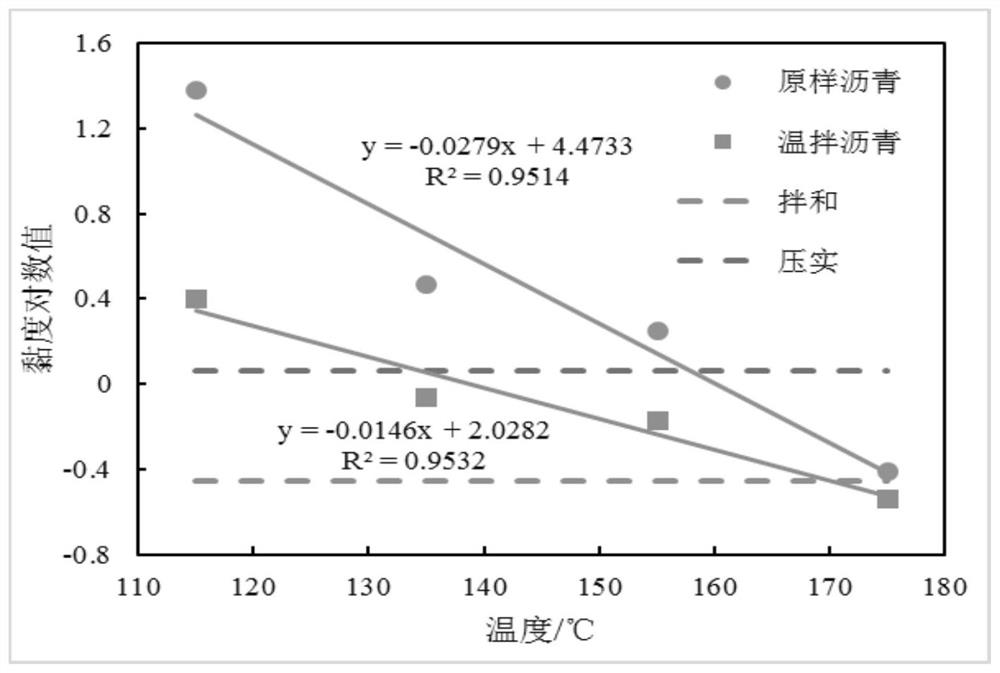

[0036] (2) 300 g of SBS-modified asphalt heated to 160° C. was weighed in each of five 600-ml beakers. All samples were placed in a holding furnace at 160 ℃ ~ 165 ℃, and 4.5g, 7.5g, 10.5g, 13.5g, 16.5g of organic viscosity reducing and temperature mixing agent A (recommended dosage of 3% to 4%) were added. The interval is 1%, that is, 5 dosage gradients such as 1.5%, 2.5%, 3.5%, 4.5%, and 5.5% are selected for the dosage. During the adding process, stir quickly and evenly, and continue stirring for 8 to 10 minutes after the addition is completed. , so that it i...

Embodiment 2

[0042] The method for quickly obtaining the optimum dosage of the organic viscosity-reducing temperature-mixing agent and the cooling range of the warm-mix asphalt mixture according to the present invention comprises the following steps:

[0043] (1) Preparation of experimental instruments, prepare 600mL beakers, stirring rods, five sets each, oven, holding furnace and electronic balance (accurate to 0.01g), one set;

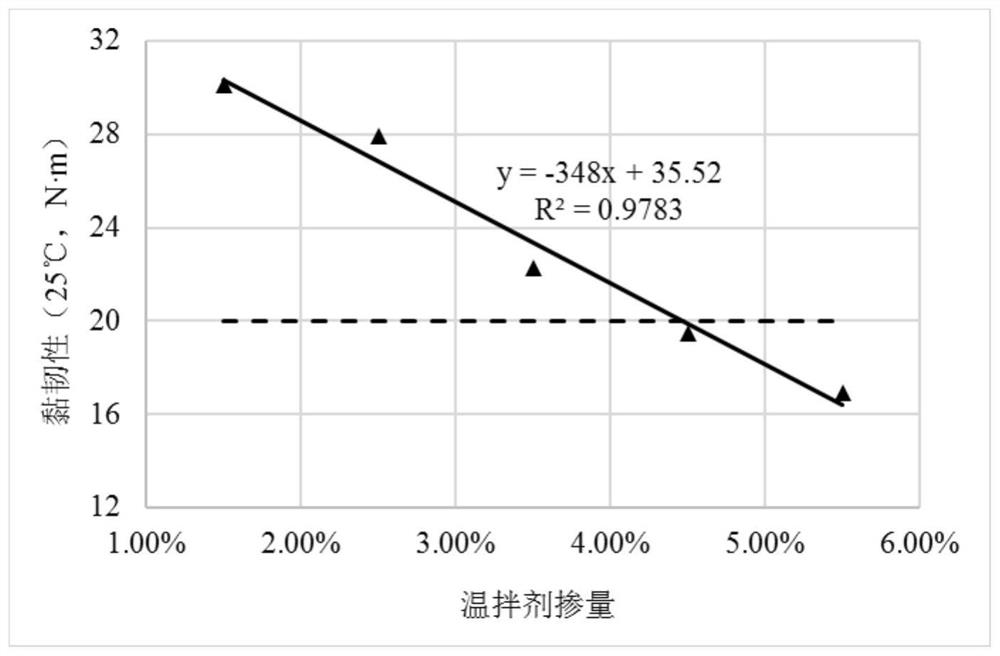

[0044] (2) Weigh 300 g of the finished high-viscosity asphalt heated to 175° C. in each of five 600-ml beakers. All samples were placed in a holding furnace at 175°C ± 5°C, and 4.5g, 7.5g, 10.5g, 13.5g, 16.5g of organic viscosity-lowering and temperature-reducing agent A (recommended dosage of 3% to 4%) was added, respectively. The interval is 1%, that is, 5 dosage gradients such as 1.5%, 2.5%, 3.5%, 4.5%, and 5.5% are selected for the dosage. During the adding process, stir quickly and evenly, and continue stirring for 8 to 10 minutes after the addition is comple...

Embodiment 3

[0050] The method for quickly obtaining the optimum dosage of the organic viscosity-reducing temperature-mixing agent and the cooling range of the warm-mix asphalt mixture according to the present invention comprises the following steps:

[0051] (1) Preparation of experimental instruments, prepare 600mL beakers, stirring rods, five sets each, oven, holding furnace and electronic balance (accurate to 0.01g), one set;

[0052] (2) 300 g of SBS-modified asphalt heated to 160° C. was weighed in each of five 600-ml beakers. All samples were placed in a holding furnace at 160 ℃ ~ 165 ℃, and 6g, 7.5g, 9g, 10.5g, 12g of organic viscosity-lowering and temperature-reducing agent B were added (recommended dosage 2.5%~3.5%), and the dosage interval was 0.5 %, that is to say, the dosage is selected from 5 dosage gradients such as 2.0%, 2.5%, 3.0%, 3.5%, and 4.0%. During the addition process, stir quickly and evenly. After the addition is completed, continue to stir for 8 to 10 minutes to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com