Magnesium-rich nickel slag geopolymer porous material and preparation method thereof

A technology of geopolymer and magnesium-nickel slag, which is applied in the fields of ceramic products, solid waste management, sustainable waste treatment, etc., can solve the problems of adverse impact on the ecological environment, polluted soil and groundwater, and large land occupation, and achieves the goal of promoting Reasonable utilization and environmental protection, high utilization rate of solid waste and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

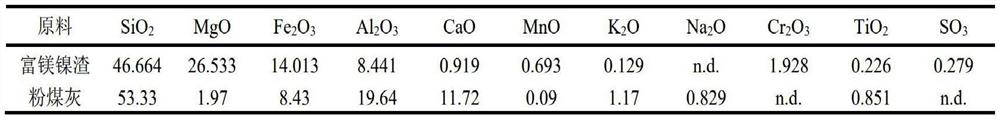

[0042]A preparation method of magnesium-rich nickel slag geopolymer porous material, comprising the following steps:

[0043] S1, put the raw material (particle diameter<3mm) of preliminary crushing into ball mill and grind, pass 200 mesh sieves after grinding to obtain the required fineness raw material;

[0044] S2, mixing the foam stabilizer and water to prepare a mixed solution;

[0045] S3, mixing the activator and the mixed solution to prepare the activator mixed solution;

[0046] S4. Add the activator solution to the uniformly mixed magnesium-nickel slag and fly ash, stir and mix to obtain a clean slurry;

[0047] S5, mixing the clean pulp and foaming agent to prepare foam homogenate;

[0048] S6. The homogenate is poured into a mold of 100 mm×100 mm×100 mm for molding, and then cured to obtain a porous material of green solid waste.

[0049] Further, after solidification and molding in the step S6, the mold poured with the clean slurry is sealed and then placed in ...

Embodiment 1

[0054] This embodiment provides a green porous material based on magnesium-rich nickel slag and fly ash. The contents of each component of the porous material are: 70-90% for magnesium-rich nickel slag and 10-30% for fly ash 10-40% of activator (phosphoric acid), 20-40% of deionized water, 0.1-10% of foaming agent (hydrogen peroxide), and 0.1-2% of foam stabilizer (sodium lauryl sulfate).

[0055] The green porous material based on magnesium-rich nickel slag and fly ash is obtained through the following steps:

[0056] Powder refinement: put the magnesium-nickel slag and fly ash in an oven, and bake until the quality does not change. After cooling to room temperature, the magnesium-nickel slag is ball-milled with a ball mill, and then passed through a 200-mesh sieve, and the fly ash is directly Pass 200 mesh sieve;

[0057] Prepare mixed solution: foam stabilizer and water are mixed with mixed solution, after cooling for subsequent use;

[0058] Preparation of activator solu...

Embodiment 2

[0063] This embodiment provides a green porous material based on magnesium-rich nickel slag and fly ash, the content of each component of the porous material is respectively: 50-70% of magnesium-rich nickel slag, 30-50% of fly ash , activator (NaOH) 10-40% (solid content), deionized water 20-40%, foaming agent (aluminum powder) 0.1-10%, foam stabilizer (sodium lauryl sulfate) 0.9-3% .

[0064] The green porous material based on magnesium-rich nickel slag and fly ash is obtained through the following steps:

[0065] Powder refinement: put the magnesium-nickel slag and fly ash in an oven, and bake until the quality does not change. After cooling to room temperature, the magnesium-nickel slag is ball-milled with a ball mill, and then passed through a 200-mesh sieve, and the fly ash is directly Pass 200 mesh sieve;

[0066] Prepare mixed solution: foam stabilizer and water are mixed with mixed solution, after cooling for subsequent use;

[0067] Preparation of activator solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com