Lanthanum oxide accelerated permeation large-permeation-layer and high-quality salt bath boron-vanadium co-permeation agent and co-permeation process

A technology of co-penetrating agent and lanthanum oxide, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of poor surface quality, slow infiltration rate, thin infiltration layer, etc., to reduce friction coefficient, Good toughness and wear resistance, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

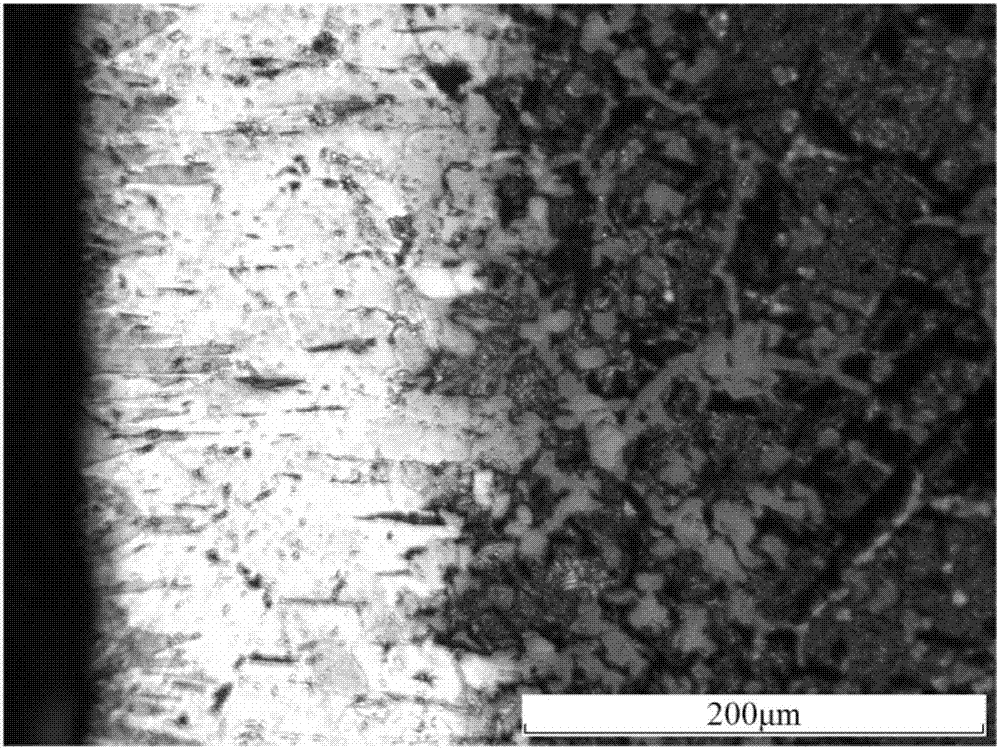

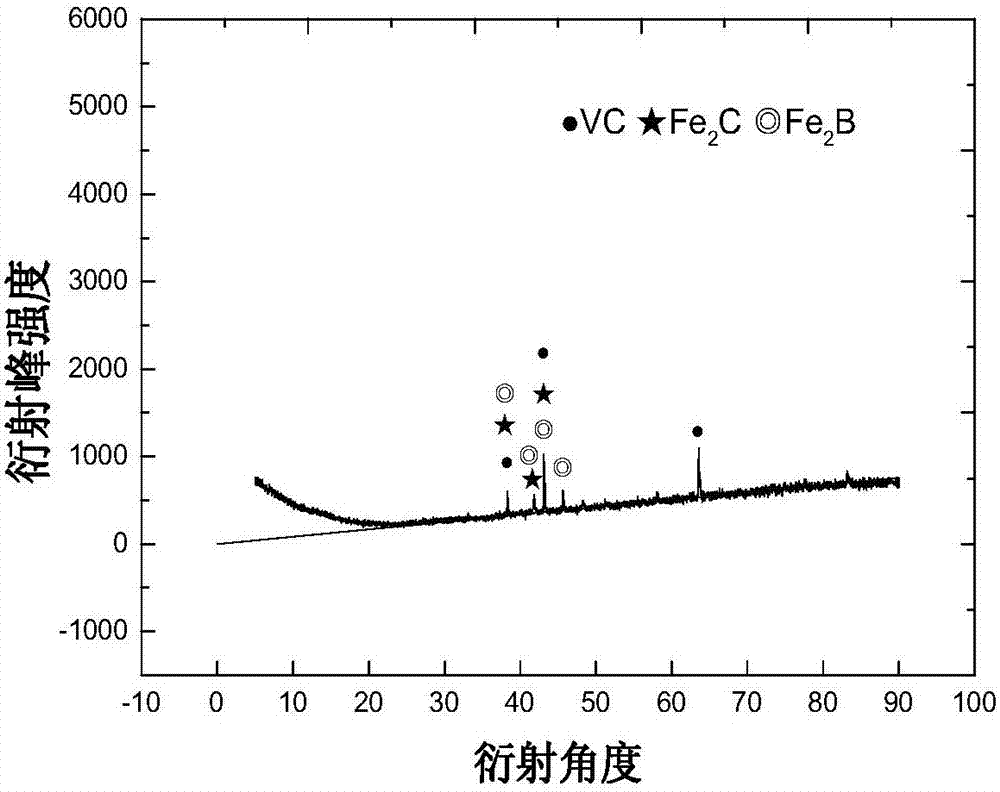

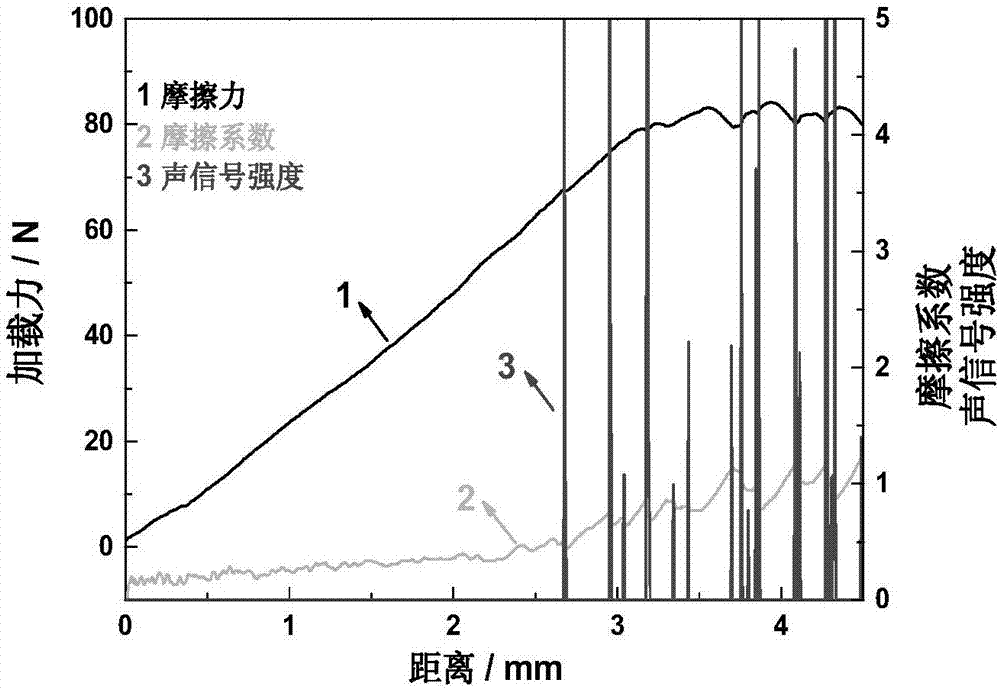

[0032] Such as Figure 1-4 shown.

[0033] The salt bath boron vanadium co-penetrating agent of the present embodiment is made of lanthanum oxide (La 2 o 3 ) 0.5g, boron oxide (B 2 o 3 ) 50.74g, sodium fluoride (NaF) 25.87g, vanadium pentoxide (V 2 o 5 ) 9.95g, barium chloride (BaCl 2 ) 7.96g, boron carbide (B 4 C) 4.98g composition.

[0034] The boron-vanadium co-infiltration process is: sample surface pretreatment-boron-vanadium co-infiltration treatment-cleaning the sample

[0035] (1) Weigh the raw materials according to the mass percentage of the boron-vanadium co-infiltration agent formula and mix them uniformly mechanically and put them in the crucible for later use; it is best to mechanically mix the prepared salt bath boron-vanadium co-infiltration agent and place it in corundum Cover the crucible, seal it with high-temperature sealant, put it in an oven and dry it at 100°C for 45 minutes.

[0036] (2) Base material pretreatment: the base material of the pre...

Embodiment 2

[0041] Such as Figure 5 shown.

[0042] The salt bath boron vanadium co-penetrating agent of the present embodiment is made of lanthanum oxide (La 2 o 3 ) 0.2g, boron oxide (B 2 o 3 ) 50.87g, sodium fluoride (NaF) 25.98g, vanadium pentoxide (V 2 o 5 ) 9.98g, barium chloride (BaCl 2 ) 7.98g, boron carbide (B 4 C) 4.99g composition.

[0043] The boron-vanadium co-infiltration process is: sample surface pretreatment-boron-vanadium co-infiltration treatment-cleaning the sample

[0044] (1) Weigh the raw materials according to the mass percentage of the boron-vanadium co-infiltration agent formula and mix them uniformly mechanically and put them in the crucible for later use; it is best to mechanically mix the prepared salt bath boron-vanadium co-infiltration agent and place it in corundum Cover the crucible, seal it with high-temperature sealant, put it in an oven and dry it at 100°C for 45 minutes.

[0045] (2) Base material pretreatment: the base material of the prese...

Embodiment 3

[0050] Such as Figure 6 shown.

[0051] The salt bath boron vanadium co-penetrating agent of the present embodiment is made of lanthanum oxide (La 2 o 3 ) 1g, boron oxide (B 2 o 3 ) 50.49g, sodium fluoride (NaF) 25.74g, vanadium pentoxide (V 2 o 5 ) 9.9g, barium chloride (BaCl 2 ) 7.92g, boron carbide (B 4 C) 4.95g composition.

[0052] The boron-vanadium co-infiltration process is: sample surface pretreatment-boron-vanadium co-infiltration treatment-cleaning the sample

[0053] (1) Weigh the raw materials according to the mass percentage of the boron-vanadium co-infiltration agent formula and mix them uniformly mechanically and put them in the crucible for later use; it is best to mechanically mix the prepared salt bath boron-vanadium co-infiltration agent and place it in corundum Cover the crucible, seal it with high-temperature sealant, put it in an oven and dry it at 100°C for 45 minutes.

[0054] (2) Base material pretreatment: the base material of the present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com