Method for degumming sesame oil

A sesame sesame oil, degumming technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problem that non-hydratable phospholipids are difficult to remove, and achieve good fragrance retention effect, high stability, and short removal time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

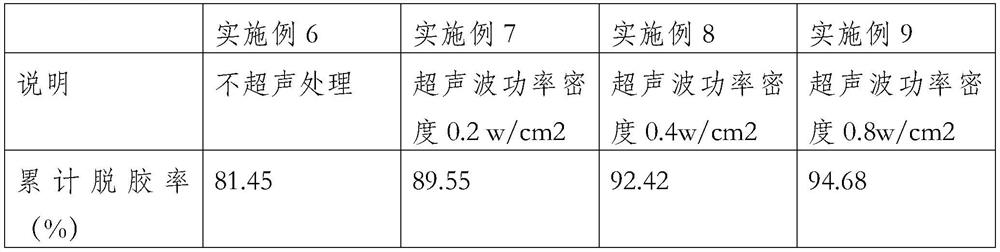

Examples

Embodiment 1

[0027] This example provides a method of sesame oil delash:

[0028] (1) Prepare the amount of sesame oil purifier and the amount of phosphorium is 1000 mg / kg;

[0029] (2) The concentration of 50% citric acid solution; 50% of the citric acid solution was added to sesame oil, and its added amount was 0.30%, added 4.00% water, at a temperature of 62 ° C, ultrasonic power density 0.4 W / cm 2 After 25 minutes of treatment time, centrifuge at 8000 r / min, 10 min, collect the upper oil layer, i.e., the product obtained after acid method dehydration;

[0030] (3) The compound enzyme formula is a phosphatidase Lecitase Ultra: phospholipase C = 1: 1, concentration of 0.8%, dosage 250mg / kg sesame oil, ultrasonic power density 0.6W / cm 2 The treatment time is 55min, the treatment temperature is 58 ° C; the enzymatic sesame oil is tapered to 90 ° C, and the enzyme is 10 min, centrifuged at 8000 r / min for 10 min, and the upper oil layer is collected from the sesame oil, and the cumul...

Embodiment 2

[0032] This example provides a method of sesame oil delash:

[0033] (1) Prepare the amount of sesame oil purifier and the amount of phosphorium is 1000 mg / kg;

[0034] (2) The concentration of 50% citric acid solution; 50% of the citric acid solution was added to sesame oil, and its added amount was 0.30%, added 4.00% water, at a temperature of 62 ° C, ultrasonic power density 0.4 W / cm 2 After 25 minutes of treatment time, centrifuge at 8000 r / min, 10 min, collect the upper oil layer, i.e., the product obtained after acid method dehydration;

[0035] (3) The compound enzyme formula is a phosphatidase Lecitase Ultra: phospholipase C = 1: 2, concentration of 0.8%, dosage 250mg / kg sesame oil, ultrasonic power density 0.6W / cm 2 The treatment time was 55min; the enzymatic sesame oil was warmed to 90 ° C, and the enzyme was rt, centrifuged at 8000 R / min for 10 min, and the upper oil layer was collected to obtain sesame oil, and the cumulative degummion reached 95.15%.

Embodiment 3

[0037] This example provides a method of sesame oil delash:

[0038] (1) Prepare the amount of sesame oil purifier and the amount of phosphorium is 1000 mg / kg;

[0039] (2) Citric acid solution having a concentration of 50 to 60%; add 50% of the citric acid solution to sesame artifice oil, which is 0.30%, add 4.00% water, at a temperature of 62 ° C, ultrasonic power Density 0.4W / cm 2 After 25 minutes of treatment time, centrifuge at 8000 r / min, 10 min, collect the upper oil layer, i.e., the product obtained after acid method dehydration;

[0040] (3) The compound enzyme formulation is phosphatidase Lecitase Ultra: phospholipase C = 2: 1, concentration of 0.8%, used in dosage 250mg / kg sesame oil, ultrasonic power density 0.6W / cm 2 The treatment time was 55 min; the enzymatic sesame oil was warmed to 90 ° C, and the enzyme was ly enzyme 10 min, and centrifuged at 8000 r / min for 10 min, and the upper oil layer was collected to obtain sesame oil, and the cumulative degummi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com